Test Taping Consistent Machine

Model: SY-1906

High automation, automatic troubleshooting, automatic tape cutting, etc., maximize production efficiency and reduce manual operations, so that one person can watch multiple devices at the same time;

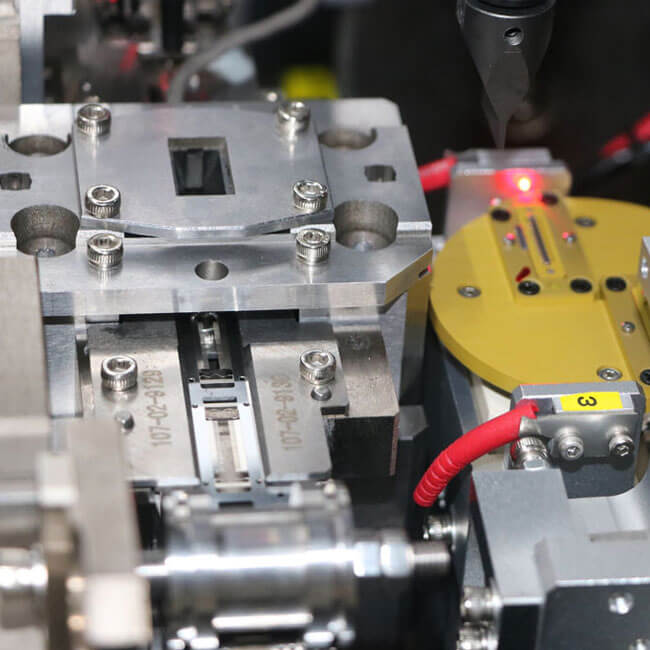

Vibration plate: The front end of the direct vibration track is specially optimized to ensure reliable separation of materials;

Positioning mechanism: using motor control, precise, low noise and sensitive response;

Modular Design

Structural modular design (universal)

Easy adjustment of mechanism parts (microcards, etc.)

Modules are easy to replace and low cost

Smart production

Connection of MES system

Human-machine linkage

Fast data transfer and storage

Good stability and high detection accuracy

High-strength machined precision parts

100% brand electronic components

The most mature testing institution and the most leading brand CCD inspection system

Specification Parameters

|

Adapt to the product |

Semiconductor components such as QFN, BGA, IC, integrated circuit, crystal oscillator, etc. |

|

UPH |

15K/H (related to test time and marking time) |

|

Sealing method |

Heat sealing/self sealing |

|

Operation method |

Touch screen |

|

Carrier tape width |

8-32mm |

|

Statistics function |

Production data statistics, yield statistics |

|

Visual system |

Detection of size, appearance defects, characters, etc. |

|

Feeding method |

Manual feeding/automatic feeding |

|

Feeding method |

Vibrating plate |

|

MTBA |

≥1Hr |

|

Filling accuracy |

100% |

|

Detection accuracy |

99.50% |

|

Machine size |

1600*780*1810mm (length, width and height) |

|

Machine weight |

350KG |

|

Power supply |

220V 50HZ |

|

Gas source |

0.5Mpa |

|

Rated power |

1100W |

|

Test function |

Select the test machine according to the test content |

|

Marking function |

Laser marking / inkjet typing |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky