Solder Dross Recovery Machine SD09F

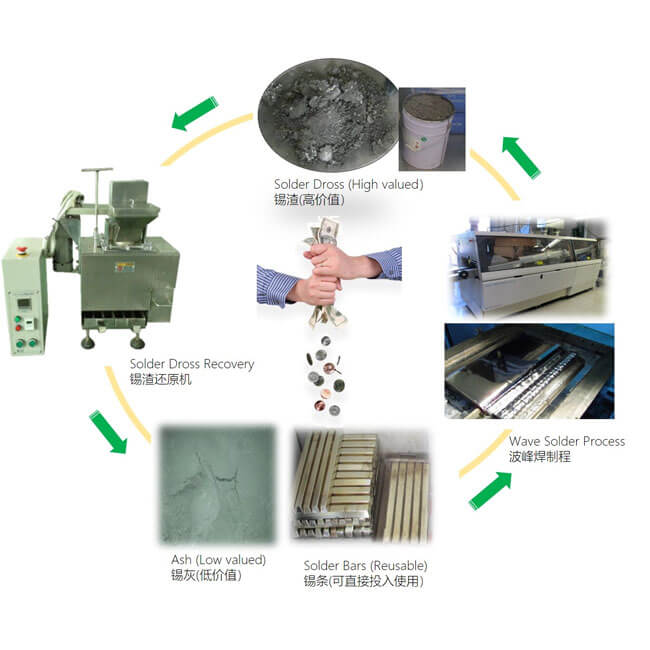

This equates to a reduction in your solder usage of up to 50% for the same amount of production, the alloys separation rate is up to 98%, economic design with a small footprint and easy to transport, offline or inline operation without dust, High recovery ration, medium capacity.

Feature :

■ Pure physical separation without using any chemicals.

■ Tin alloy separation rate is up to 98%.

■ The recycled solder bar can be directly use for wave soldering.

■ Compact in size, all stainless steel and is easy to maintain.

■ Patented mixing and separation system for improved separation efficiency.

■ Solder pot is made of corrosion resisting ss 316L material with has a long service life.

■ The unit uses a “U” shape heater covered cast iron heating plate, which will avoid deformation.

■ OMRON temperature controller and SSR relay ensure accurate temperature control and long service life.

■ Machine will alarm when separated solder is in the cabin and reaches the full volume, this indicates to discharge the solder.

■ Machine is equipped with 2 sets of molding tray, which are convenient for forming solder bars.

■ Reclaim capacity is about 6KG/Hr, it can be embedded inside wave soldering machine as an inline machine.

■ Separated tin oxide ash will collect in separate box, for easy disposal.

■ Asset payback period <6 months.

■ CE is optional and available.

■ 15 years of R&D and sales in WW.

Specifications :

|

Model |

SD800 |

SD10MS |

SD09F |

|

Power Supply |

3P 4¢ 380V @50HZ |

1phase 220v @50HZ |

1phase 220v @50HZ |

|

Connected Power |

5.8KW |

4.5KW |

2KW |

|

Normal Running Power |

1.8KW |

1.5KW |

1.0KW |

|

Bottom Tin Capacity of Mixing Zone |

100Kg |

70Kg |

10Kg |

|

Heating-up Time |

60mins |

60mins |

50mins |

|

Controlling System |

HMI+PID |

PID + Buttons |

PID + Buttons |

|

Reclaim Capacity |

30Kg/Hr. |

15Kg/Hr. |

6Kg/Hr. |

|

Solder Bar Molding Tray |

Automatic forming |

2 EA |

2 EA |

|

Net Weight Approx. |

500Kg |

110Kg |

45Kg |

|

Dimension (LxWxH mm) |

1800x1050x1600 |

680 x 850 x1050 |

500x250x650 |

|

140x330x390 |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky