Nordson AXM Nordson XM8000™ SMT X-ray Inspection Machine

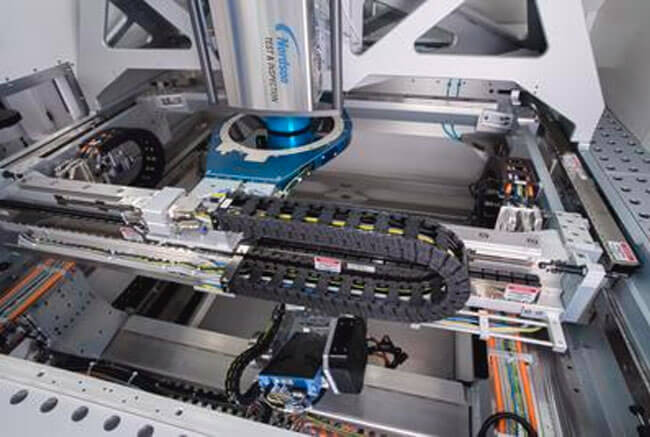

The complete solution for operator free, automated X-ray wafer metrology. Nordson XM8000™ is specifically designed for inline use in clean room environments.

Overview

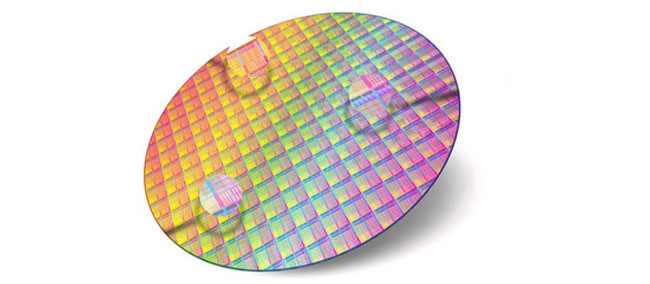

This platform takes the market-leading capabilities from Nordson Test & Inspection's existing X-ray systems to provide an automated, high-throughput X-ray metrology and defect review system for both optically hidden and visible features of TSVs, 2.5D and 3D IC packages, MEMS and wafer bumps.

The Nordson XM8000™ provides unprecedented, non-destructive, in-line wafer measurement of voiding and fill levels, overlay, critical dimensions and much more. In this way the XM8000 can be used as an integral part of the fabrication and packaging of integrated circuits or as part of quality control and product acceptance.

Measured Solutions

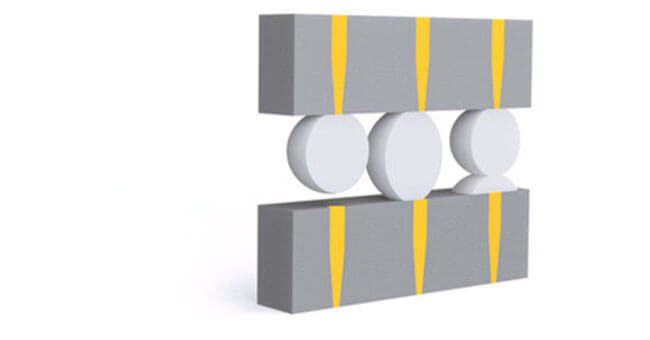

TSV Metrology

Wafer Level Packaging

XM8000-WLP enables in depth analysis of all forms of wafer level packaging. This analysis is customized for such defects such as Cold Joints, Head in Pillow (HiP), misalignment and missing features. The intelligent, self learning capability of XM8000 allows unrivaled detection of micro defects in complex packages

Intelligent Defect Analysis

Intelligent Defect Measurement

The XM8000’s intelligence provides optimum defect analysis, which eliminates the need for operator interpretation and minimizes false calls. As a fully automated system, exact measurement criteria are measured, reproduced and repeatable for consistent analysis across multiple sites, customized to the specific device.

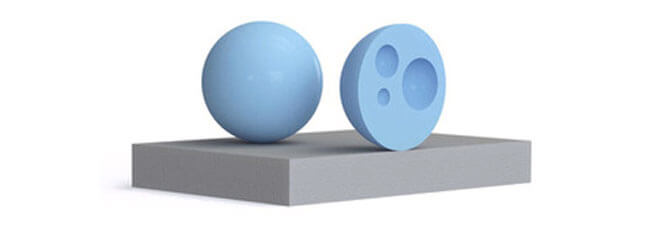

Wafer Bump Metrology

XM8000-5 WB measures wafer bump characterization including voiding, presence, position, shape, size and bridging. Unlike optical tools, XM8000-5 WB can measure voids within the wafer bump

Advantages

X-ray Metrology and Defect Review

High-throughput of optically hidden and visible features of:

TSVs

2.5D & 3D IC Packages

MEMS

Wafer Bumps

Consistency as Standard

With unrivaled GR&R to less than 5%, the XM8000 utilizes the latest high resolution stages to 1um accuracy providing supreme repeatability.

IC-Safe Radiation Shield

When selective sampling is utilized, IC-Safe shields completely eliminate radiation exposure to all other device samples not under test.

Unbeatable Performance

The XM8000 performance is unbeatable in 24/7 operation. Clean room compatible and designed to S2 and S8 standards, XM8000 fully integrates into your production process further reducing unit cost.

XM8000-7 TSV delivers high throughput metrology of TSVs. Advanced 3D techniques are used to analyze shape, fill and voiding at sub-micron levels

Jacky

Jacky Jacky

Jacky