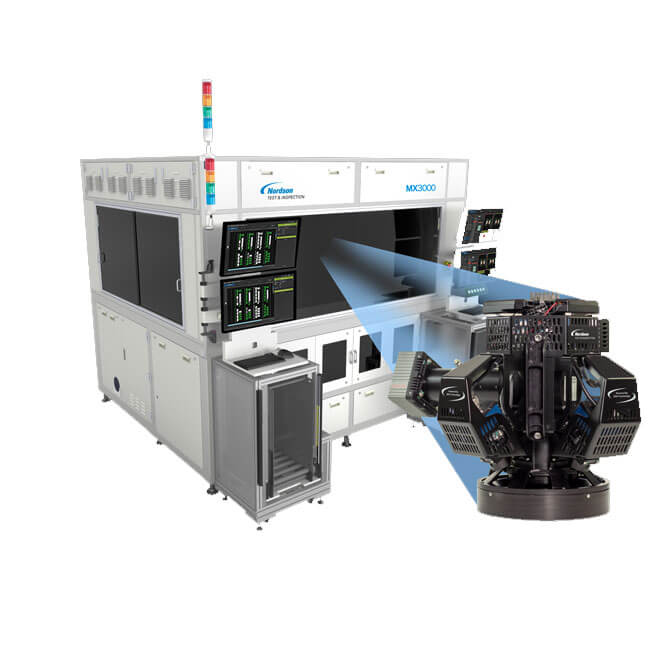

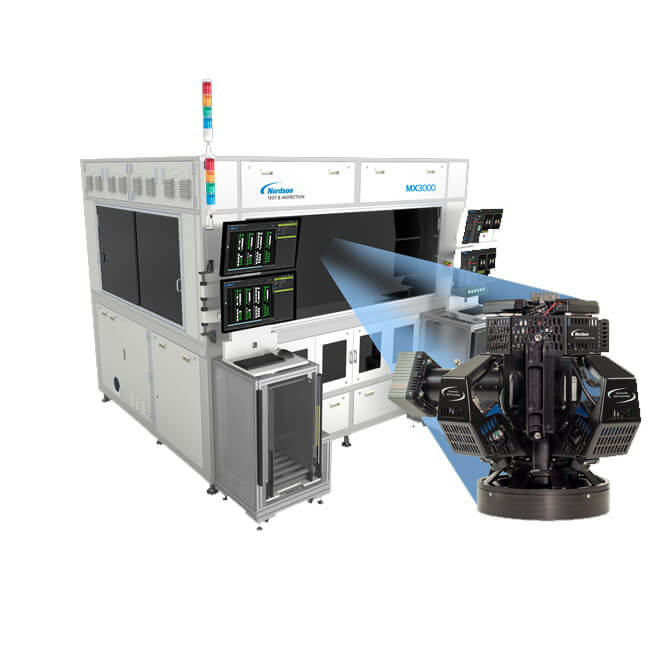

Nordson MX3000™ 3D AOI Machine

The MX3000™ is powered by CyberOptics’ breakthrough 3D sensing technology comprising of two MRS® Sensors delivering simultaneous dual-sided automated final vision inspection for singulated memory modules – for metrology grade accuracy at production speed.

Overview

Multi-Reflection Suppression® (MRS®) Technology

MX3000™ offers unmatched accuracy with the revolutionary MRS technology by meticulously identifying and rejecting reflections caused by shiny components and reflective solder joints. Effective suppression of multiple reflections is critical for highly accurate measurements making MRS an ideal technology solution for a wide range of applications including those with very high quality requirements.

Flexibility At Its Best

The MX3000™ 3D Automated Optical Inspection (AOI) system enables high resolution, dual-sided final vision inspection that doubles productivity. In-line multiple module grippers minimize handing tact time, and autoconversion supports various memory module form factors (RDIMM, SODIMM, VLPDIMM, UDIMM and others.)

Faster, Smarter Programming

With ultra-fast programming capabilities, auto tuning and other enhancements, CyberOptics’ AOI software significantly speeds set-up, simplifies the process, reduces training efforts and minimizes operator interaction.

Specifications at a Glance

|

Inspection Speed |

50 cm2/sec (2D+3D) |

|

Board Length |

Min. 25 mm / Max. 140 mm |

|

Board Width |

Min. 17 mm / Max. 35 mm |

|

Component Types Inspected |

Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header |

|

pins, and more |

|

|

3D Measurement inspection |

Lifted lead, package coplanarity, polarity dimple and chamfer identification |

|

Resolution |

Sub 10 μm |

|

Component Height Clearance (max) |

35mm |

|

Solder Joint Defects Categories |

Solder bridge, opens, lifted leads, wettability, excess and insufficient solder, debris, and more |

|

Other Items Detected |

Gold-finger contamination, pin-in-hole, bent pins, debris, OCR/OCV and many others |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky