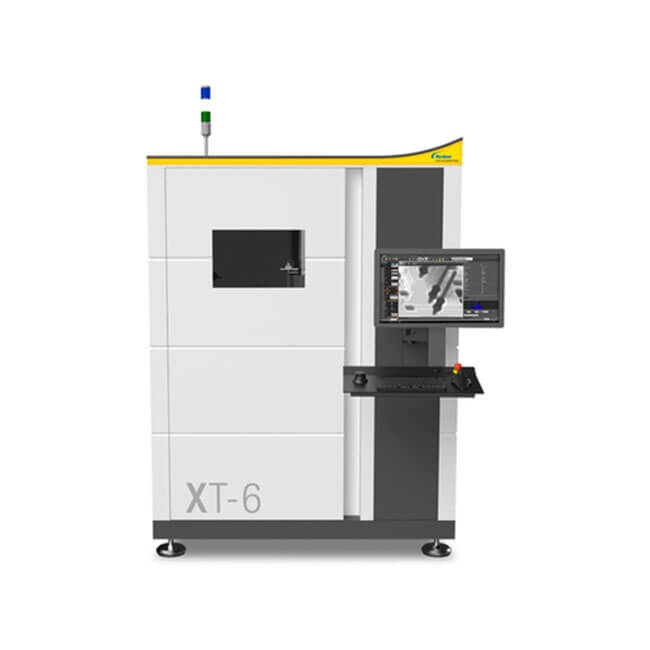

Nordson AXI XT-6 Series AXI SMT X-ray Inspection Machine

The XT-series provides the advanced inspection capability of Nordson TEST & INSPECTION's inline system in a smaller footprint manual load/island of automation system. The platforms are designed for flexibility and ease of use for a wide variety of products requiring 2D and 2.5D automated X-ray inspection. The XT-6/XT-6A platform is a highly flexible automated X-ray inspection system with minimum footprint and a parallel-kinematic Hexaglide manipulation unit for extreme-angle off-axis image acquisition with high resolution. It is suitable for high-quality X-ray analysis of electronic assemblies and material analysis of parts that require flexible part manipulation with multiple inspection angles. For batch modes and volume inspection the XT-6 can be equipped with a single-sided conveyor setup and magazine load/unload station (XT-6A).

High flexibility, island type AXI systemX-ray System Features

Flexible AXI system for manual load and island of automation configurations

Microfocus X-ray tube (sealed tube / maintenance free)

Extreme angle shot capability (up to 65 deg)

Multiple programmable motion system with servo drives

Digital CMOS flatpanel detector

Automatic grey-level and geometrical calibration

Barcode scanner for serial number and product type selection

Full product traceability via customized MES-Interface

Automatic grey-level and geometrical calibration

Full product traceability via customized MES-Interface

Highlights

Barcodereader

Heavy duty transport system

Low dose radiation filter

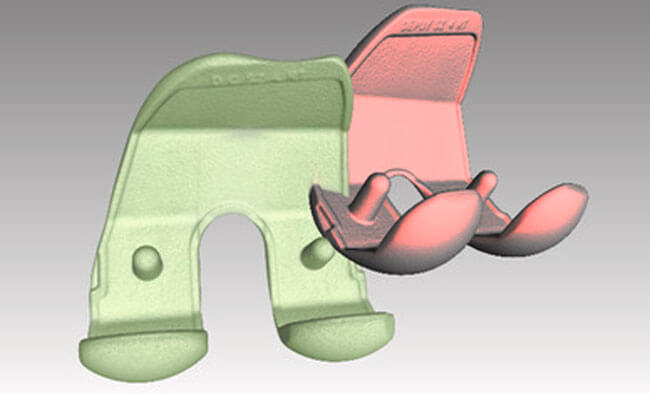

Hybrid or chip level assembly setup

Available Configurations

Depending on the type of product & inspection task

SMT setup for component and solder-joint inspection on PCB

XT-6(A) Transmission (2D) + SFT™ + Off-Axis (2.5D)

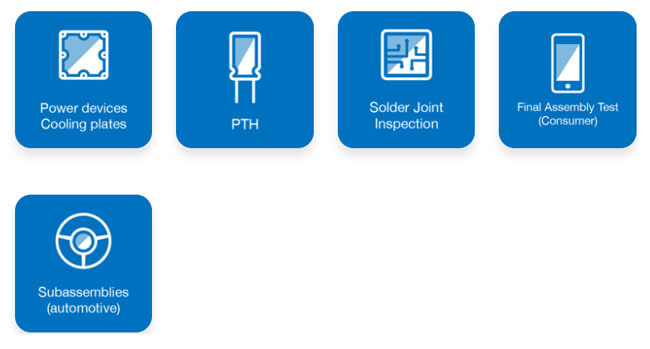

Applications

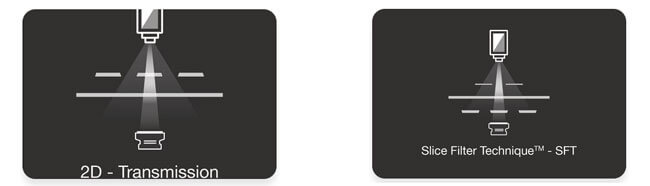

Inspection Technologies

The modular AXI system concept provides the unique capability to use several inspection technologies in one system. Depending on the specific application request the optimum inspection technique can be selected and/or combined.

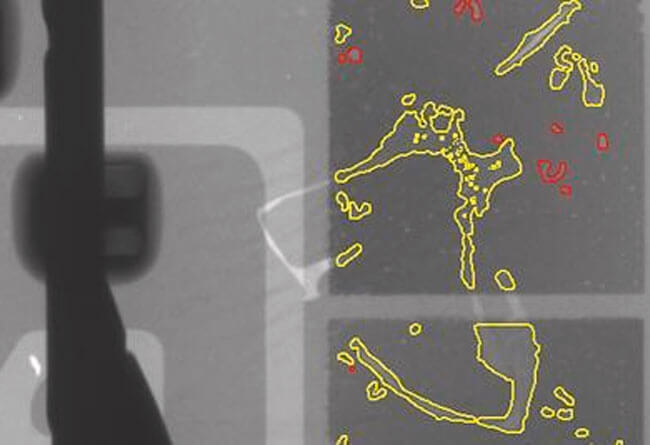

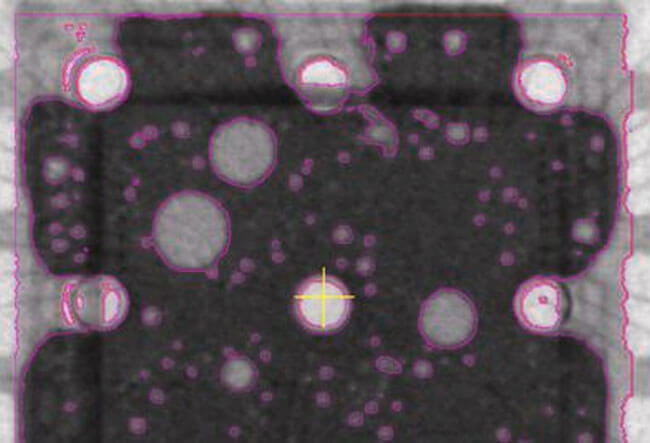

2D Transmission

Transmission is two-dimensional image capturing with a fixed detector position

SFT Slice Filter Technique

High-speed technique using first side image to filter out from double-side image

2.5D-Oblique View

AXI on programmable angle-shots up to 50 (60) dgr (used for high performance BGA and PTH inspection)

Specifications at a Glance

| Dimensions: | 1940 mm (H) x 2250 mm (W) x 1610 (D |

| Weight: | 2,000 kg |

| Safe Operating Temperature: | 15°-28°C optimal 20°-25°C |

| Power Consumption: | Max.6k W |

| Line Voltage: | 220 VAC, single phase, 16A |

| Air: | 5-7 Bar, < 21/min, filtered (30μ), dry, oil free |

| X-ray Source (sealed tube) | |

| Energy: | SMT-Setup |

| 120 kV / 40 W | |

| Grey resolution: | up to 14 Bit |

| Detector Types: | |

| CMOS Flatpanel Detector | 50 μm pixel size ( 5 MPix) |

| 75 μm pixel size ( 3 MPix) | |

| Parallel-kinematic Hexaglide unit with 6 axes | |

| x,y (linear drives) | sample table |

| Position repeatability | +/- 5 mm |

| X-ray tube (sealed): | Z-drive |

| Handling | |

| XT-6A | single lane, |

| in-out same side[ | |

| Inspection features | |

| Max. sample size | 400 mm to 350 mm |

| Max. inspection area | 400 mm to 350 mm |

| Min. sample size | 100 mm to 50 mm |

| Sample thickness | 0,8 - 10 mm |

| Max. sample weight: | 5 kg |

| Angle shot capability: | 0 - 65 dgr |

| Resolution | down to 3 μm / pix |

| Assembly clearance | |

| Topside (incl. board thickness): | 160 mm |

| Bottom side (excl. board thickness) | 35 mm |

| Min. edge clearance for clamping: | 3 mm |

| Inspection speed | |

| Transmission | up to 2 images /s |

| Off-Axis | up to 2 images /s |

| Options | |

| Barcodereader | |

| Heavy duty transport system | |

Jacky

Jacky Jacky

Jacky