SAKI 3Xi-M200 3D AXI SMT X-ray Inspection Machine

A 3D-CT X-ray inspection system that is ideal for Power module inspection with multi-layered solder, the 3D-AXI achieves the industry’s fastest speed inspection while reliably detecting difficult defects such as voids in three-layer soldering.

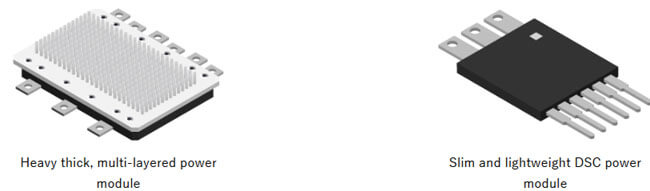

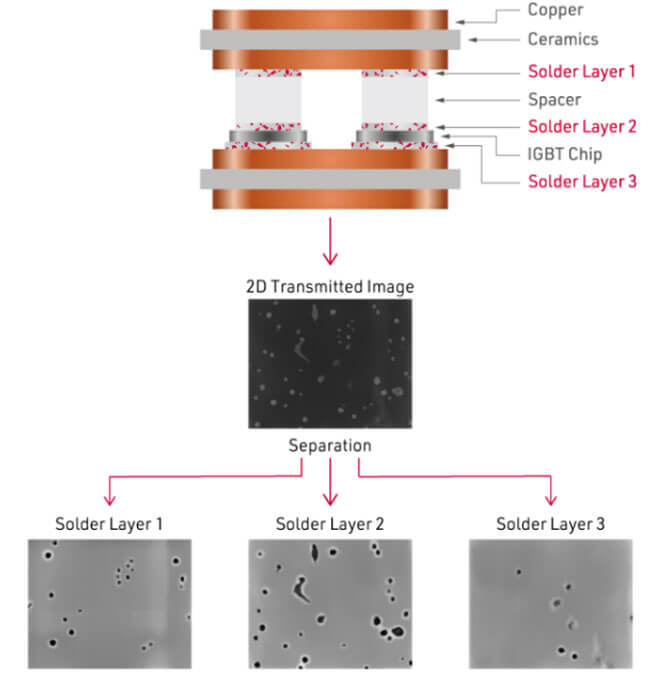

Power module with multi-layered solder that Saki can inspect

Unrivaled Defect Detection Ability with 3D-CT X-Ray Inspection

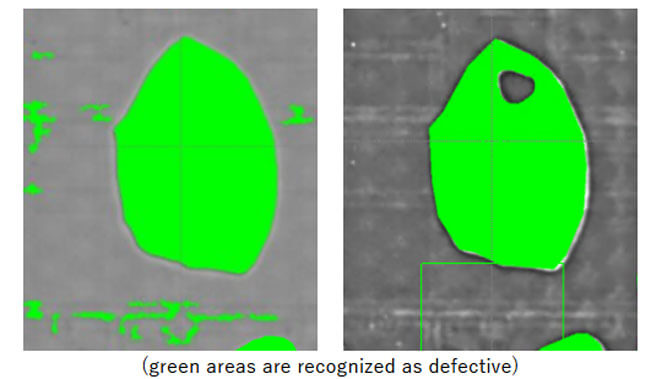

Accurately detects thin voids that are historically problematic for inspection

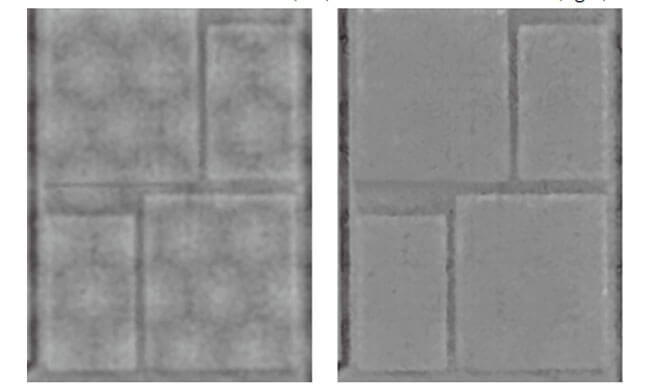

Image noise removal is achieved by separating the solder layer and heat dissipation fins

Planar CT technology suitable for solder layer separation

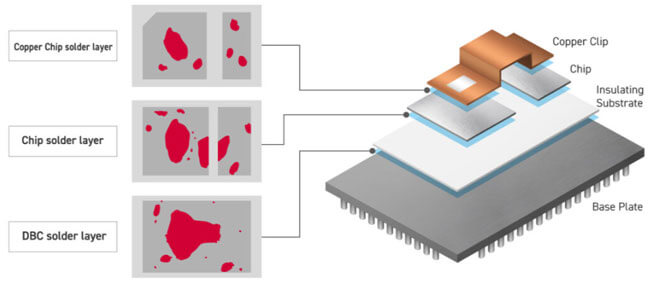

In power module, 2D inspection using X-rays from directly above makes it impossible to measure voids because the solder layer overlap with heat dissipation fin and spacer.

With Saki’s unique Planar CT technology, which specializes in imaging flat objects, each solder layer is separated to accurately detect voids.

Cross-sectional image of IGBT power module

Saki’s high-precision hardware design is essential for the creation of high-definition 3D data. The ultra-rigid gantry and high-resolution linear scale provide incredible accuracy in positioning for stable imaging.

Gantry position information is reflected in real-time calculations to obtain high-definition 3D images with clear edges.

Saki’s high-precision hardware design is essential for the creation of high-definition 3D data. The ultra-rigid gantry and high-resolution linear scale provide incredible accuracy in positioning for stable imaging.

Gantry position information is reflected in real-time calculations to obtain high-definition 3D images with clear edges.

Highly accurate void inspection

Prior to application of the noise cancellation filter, artifacts other than the central void are also detected (left image). After filter application, the shape of the defect is detected more accurately (right image).

Before Noise Cancelation (left) After Noise Cancelation (right)

Supports inspection of Slim and lightweight DSC power module

Recently, advances in DSC technology have led to an increase in the number of slimmer and lighter power modules.

Sectional view of DSC power module

Debug without stopping the production line

The offline debugging function enables the collection and debugging of images without stopping the operating equipment. Alongside real-time library updates, a catalogue of historic defect data is saved and can be re-inspected, significantly contributing to overall quality assurance.

Industry’s Fastest Inspection Speed

High-speed inspection achieved through multiple concurrent wide-area imaging processes

Optimized calculation processing means imaging and calculation processing are completed almost simultaneously

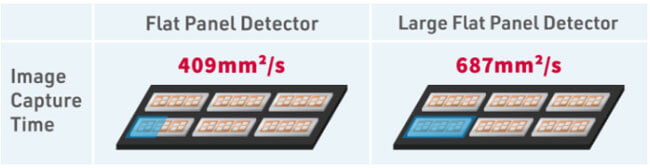

Imaging time reduced with expanded detector field of view

Saki’s latest technology, all developed in-house, has increased the scan speed by 64%*.

Reducing the cycle time by transporting large jigs

An improved conveyor design allows for the loading of larger carriers, now up to 460mm x 600mm. Through batch imaging and inspection of multiple samples, cycle time is decreased, preparation time is shortened, and operator workload reduced, especially during tray setting.

Imaging process optimization with unique CT calculation technology

Saki’s combined hardware and software development ensures optimal image processing, with CT calculations presenting almost zero delay to the inspection process.

Ease of Maintenance

Long-life hardware design

Self-diagnostic function, X-ray dosage simulator and reduction

Long-life hardware design

High-precision, accurate, and stable inspections in a mass production environment require quality, durable hardware.

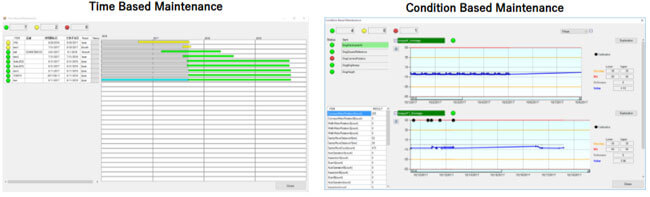

Self-diagnostic functions

Sustaining high-precision, high-accuracy inspection is important to maintain high productivity.

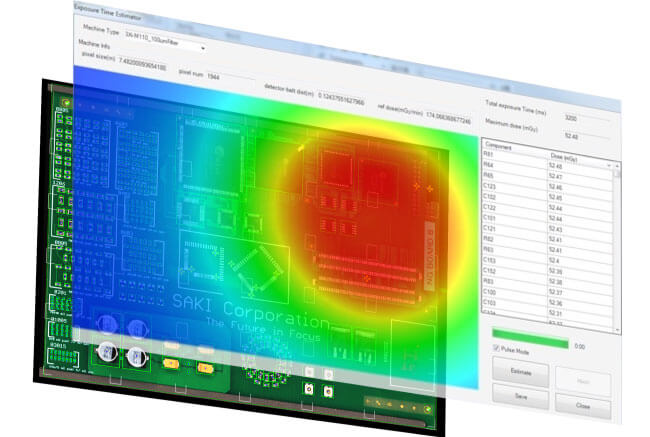

X-ray Dosage Simulator

When performing X-ray inspections, many people are concerned about the risk of component failure due to radiation exposure.

Saki’s X-ray inspection equipment is equipped with an exposure dose simulator, predicting the exposure dose for each area to optimize imaging conditions. X-rays are irradiated only during imaging, minimizing irradiation.

X-ray dosage simulator

Pass / fail judgments are made by measuring the void area of the solder layer. The noise cancellation filter of the new void inspection algorithm accurately detects thin voids that have been historically problematic for inspection.

Even with such multi-layer components, Saki’s 3Xi-M200 can clearly separate layers such as spacers from multiple solder layers and detect void defects.

This is achieving imaging speed equivalent to our PCB AXI (M110).

Additionally, the integration of a large, high-sensitivity detector enables the capture of high-quality images in significantly less time.

*Compared to our previous model

Saki’s X-ray inspection machine features a unique ultra-rigid gantry that results in a long equipment lifetime and high repeatability. Designed for the easy replacement of parts, maintenance is greatly improved, while Saki’s new detector offers significantly reduced component radiation thanks to its redeveloped lead protection design.

Saki’s X-ray inspection equipment regularly diagnoses the deterioration of the X-ray source, uneven image brightness, frame distortion, and more. Maintenance can be carried out in a planned manner and high-accuracy can be maintained.

Self-diagnosis prevents sudden equipment failure, reduces equipment downtime, prevents unnecessary replacement of non-defective parts, and reduces maintenance man-hours.

Specification

Model

3Xi-M200

Size

1400x2176x1862 (55.12 x 85.67 x 73.31 in)

(W) x (D) x (H)mm (in.)

Resolution

15μm-42μm

PCB Clearance

Top : 68mm (2.68 in.)

Bottom : 40mm (1.57 in.)

Electric Power Requirement

Three Phase 200-240V +/-5%, 50/60Hz

X-ray Tube

180kV, Closed X-ray Tube

X-ray Leakage

0.5μSv/h以下

PCB Size

50×460 – 140×440 (1.97 x 18.12 – 5.52 x 17.33 in.)

(W) x (L) mm (in.)

70×460 – 140×600 (1.97 x 18.12 – 5.52 x 23.63 in.)*

Jacky

Jacky Jacky

Jacky