VISCOM X8068 3D SMT X-ray Inspection Machine

X8068 — Fast and convenient for excellent X-ray results

Whether it's for the fast and powerful random sample analysis of special components or for automated and smooth series inspection of large assembly loads – X8068 ensures that you are equipped with the ideal system. The manual semi-automatic inspection system combines two inspection concepts in one system, the Viscom XMC and the Viscom SI analysis software. The X8068 is ideal for inspection objects up to 722 mm in diameter and inspects components up to 15 kg effortlessly. The open, high-performance micro-focus X-ray tube ensures the highest resolution and detail recognistion in first-class image quality. With a detector swivel range of up to 60 degrees, 2.5D X-ray inspections and a correspondingly wide inspection area can be realized. Thanks to user-friendly operation and extensive automatic analysis functions, inspection objects can be checked quickly and precisely. In addition, 3D reconstructions are made possible with Viscom XVR computed tomography. This means that the X8068 X-ray system offers optimal solutions for a wide range of inspection requirements to virtually all individual users. The long-standing and combined expertise in the field of in- and offline X-ray inspection makes Viscom X-ray systems the leading solutions in the field of manual and semi-automatic quality control.

Advantages at a glance

Two inspection concepts in one system: Viscom XMC and Viscom SI

Inspection of large heavy objects up to 15 kg

Robust inspection ability in the shortest cycle time

Especially suitable for high-mix, low-volume manufacturing

Simple and convenient system operation

Simple, fast inspection program creation

High resolution and excellent image quality

The use of high-quality system components

The leading solution for in-line and off-line X-ray inspection

Inspection scope

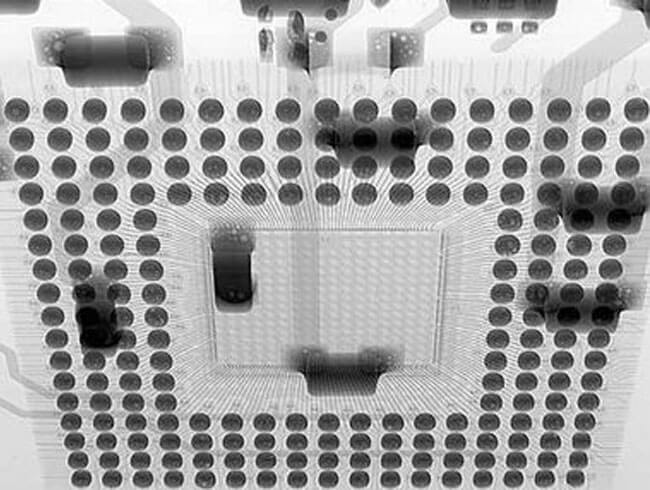

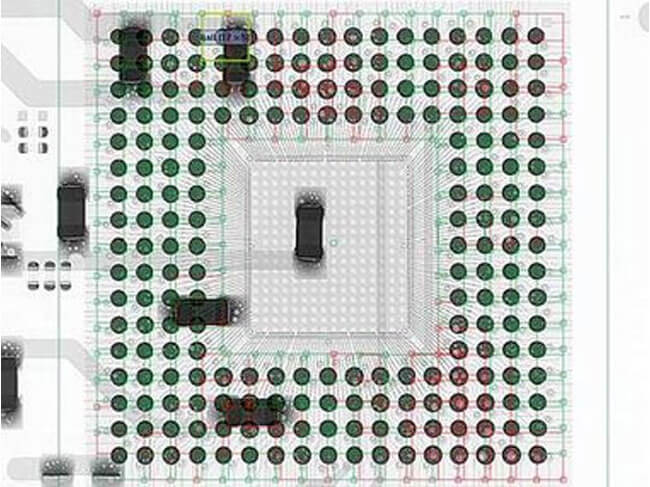

BGA overview under angled radiation

BGA defect analysis

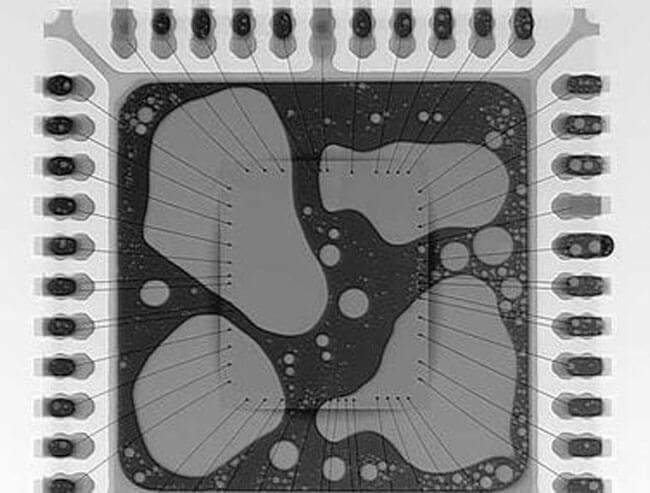

QFP orthogonal radiation

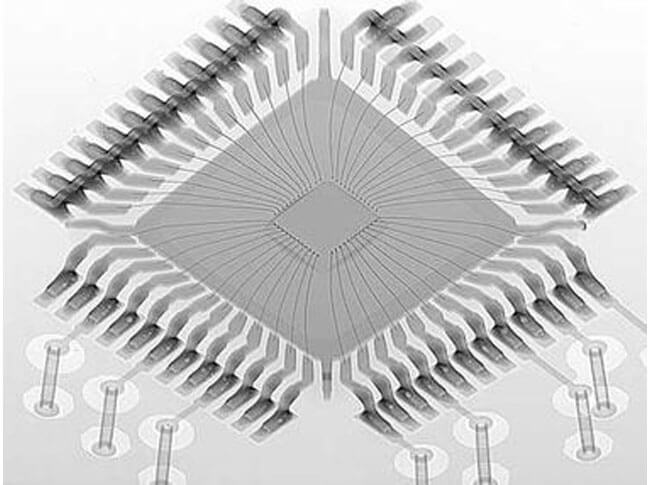

QFP under angled radiation

HIGHLIGHTS

Optimum flexibility with manual and semi-automatic inspection modes

Modular, low-maintenance all-metal tube

Flexible sample sizes up to 722 mm Ø

Variable angled radiation, simple and quick use

Excellent image quality thanks to flat-screen detectors

High resolution

All 5 axes are CNC axes

CONNECTIVITY

Customized software adaptation

Robust inspection strategies using Viscom standard library for solder joint inspection

Analysis software for BGA, QFN, THT, wire-sweep, area defect

Intuitive operation and comprehensive analytics with Viscom XMC/SI

Compatible with SMT inspection systems with Viscom SI

Independent real-time image processing with by Viscom via analysis tools

Verification station Viscom HARAN

Viscom Quality Uplink to AOI, AXI, and SPI from Viscom for process optimization

INSPECTION

Components: Electronic components and SMT components (BGA, μBGA, flip chips, and assembled circuit boards)

Solder joints: Visible and concealed solder joints

Defects/defect features: Air inclusions/blow holes in the solder joint (voids), presence, offset, too much/insufficient solder, solder bridge, solder splash (optional), soldering error, non-wetting, contamination, damaged component, missing or incorrect component, imperfect shape, tombstoning, lifted lead, billboarding, supine, twist, polarity error, wick-up effect (optional), head-in-pillow (balls), THT fill level, and pin height

Jacky

Jacky Jacky

Jacky