Nordson AXI X1 Series SMT X-ray Inspection Machine

Overview

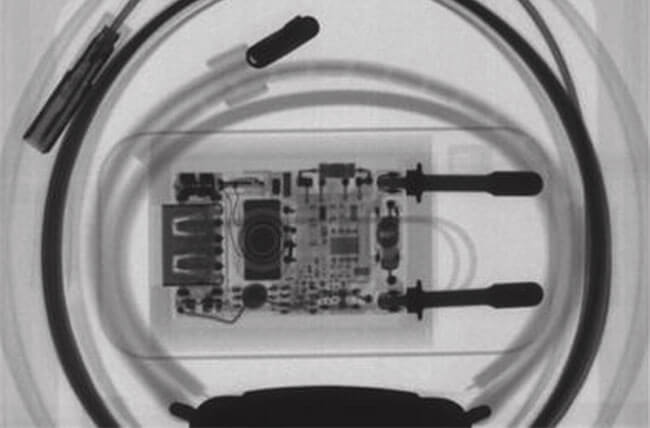

The X1# is a high-resolution, low-footprint and portable AXI system. It is a dedicated platform for FATP and advanced failure analysis applications in connection with smart devices.

High flexibility, island type AXI system

X-ray System Features

This system features a manual drawer for part loading. In order to minimize the motion range of the drawer to reduce the necessary space for the system, it showcases a parallel-slide motion system, bringing the carrier to the front of the drawer when it is pulled out.

Offline AXI system

Microfocus X-ray tube (sealed tube / maintenance free)

Digital CMOS flatpanel detector

Automatic grey-level and geometrical calibration

Barcode scanner for serial number and product type

selection

Full product traceability via various Industry 4.0 MES-Interfaces

IPC-CFX ready

Available Setups & Configurations

According to the dedicated field of application,

this system is available with the following setup:

Sealed, microfocus tube

14bit CMOS flat-panel detector

The X1# machine features the following configuration:

2D + SFT

Applications

Final Assembly Test for Consumer

Best in class final assembly inspection for complete electronic products such as smart phones, notebooks, wearables etc.

Inspection coverage (extract):

Integrity: extra and missing components/material (e.g. screws)

Missaligned components and modules (e.g. cables, connectors, screws)

Connector alignment check

Comprehensive screw test (e.g. loosen, missing, tilted screws, tightness)

Inspection via high speed X-ray line scan technique and/or multiple image capturing using latest flatpanel-detectors.

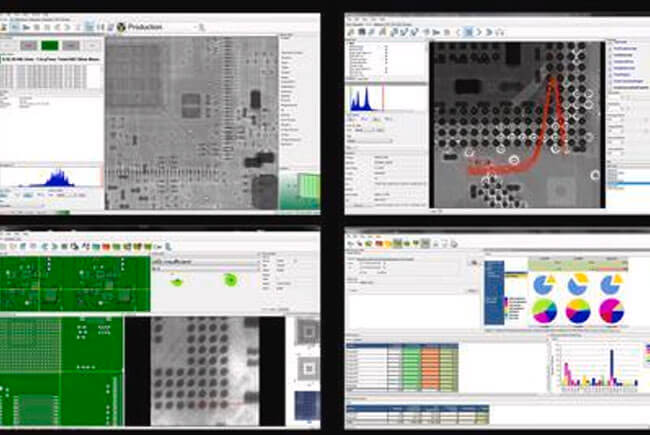

Inspection & Process Software

PC- Station with multi - core processor setup

Windows 10 platform

MIPS 5 Inspection Platform

Advanced algorithm library

CAD import for automatic inspection list generation

Automatic Tree Classification (ATC) for Auto-Rule-Generation

Offline programming for AXI program generation & simulation, tuning and defect reference catalogue

Verification & Process control

MIPS Verify link with closed loop repair

MIPS Process with real time SPC

Specifications at a Glance

| System | |

| Footprint | 1330 mm (H) x 850 mm (W) x 880 mm (D) |

| System Weight | 731 kg |

| Power Consumption | Max. 6kW |

| Line Voltage | 220 VAC, 50/60 Hz 3 phase, 16A |

| Air Supply | 6 Bar |

| Operation Temperature | 15° - 32° C optimal 20° - 25° C |

| Adjustable conveyer height (SMEMA) | 890 - 980 mm |

| Inspection features | |

| Max. carrier size | 94 mm x 54 mm |

| Max. inspection area | 50 mm x 50 mm |

| Resolution | down to 10μm /pix |

| Options | |

| Barcodereader | |

Jacky

Jacky Jacky

Jacky