Yxlon UX50 SMT X-ray Inspection Machine

With its large inspection envelope, multiple field-of-view extensions, and a powerful 450 kV X-ray tube, the UX50 takes the inspection of complex, dense parts to the next level.

UX50 highlights

Wide application range: 450 kV and large inspection envelope

Choice of line and/or flat-panel detectors for maximum flexibility

CT techniques for extended field of view and image processing

Simple creation of inspection sequences with Geminy

Automated detector calibration and image sharpness measurements

For applications e.g., in automotive, metal casting, and additive manufacturing

Maximum flexibility for quality assurance testing

Whether its massive motor blocks, larger steel parts, or complex e-mobility components – the Comet Yxlon UX50 CT system scans the most challenging items in record time. Fast switching between line and flat-panel detectors, intuitive operation with the user interface Geminy, and a comprehensive set of image processing tools make the UX50 ideal for an unlimited range of X-ray and CT applications in the industrial environment.

One system, two detectors: line detector and/or flat-panel detector

The UX50 offers a variety of detector configurations to meet the individual inspection needs of manufacturers. While CTScan 3, a line detector array (LDA) designed and produced by Comet Yxlon, is highly efficient at high energies, the Y.Panel 4343N offers more versatility. The configuration with both detectors provides the best solution for each task, allowing for quick and easy switching between the image chains in one sequence.

Easy upgrades for a future-proof investment

Simply choose the image chain that meets your current tasks and budget. If your requirements change, single detector configurations can be upgraded on site. In addition, the Geminy user interface will provide regular updates including new features.

See more of UX50 in the gallery:

Which items can be inspected with the UX50?

Components made of aluminum, steel, and superalloys

Mechatronic assemblies

Electromobility drive components and batteries

Geological samples

Fossils for paleontological research

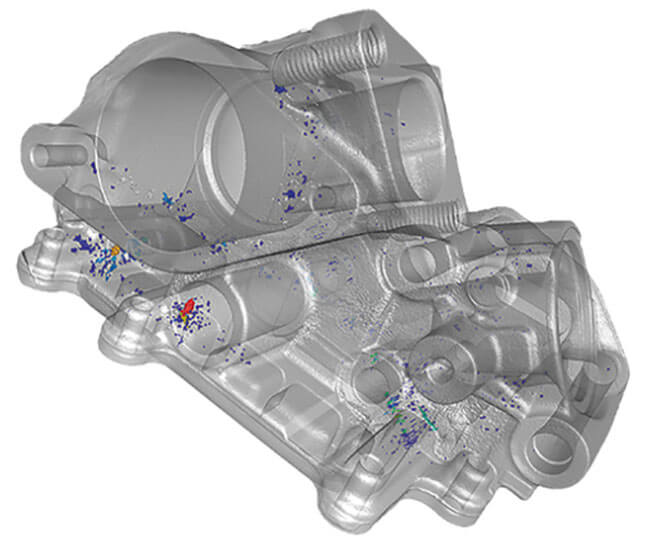

CT volume of an automotive cast part with porosity analysis

CT techniques for field-of-view extension and maximum image quality

The UX50’s powerful CT techniques facilitate the optimum part size spectrum, speed, and image quality.

Special techniques for cone-beam CT with the DDA

QuickScan® – continuous rotation image acquisition

QualityScan – start-stop image acquisition, also for ring-artifact reduction

HeliExtend – to avoid cone-beam artifacts

Horizontal and vertical field-of-view extension

Combination of horizontal and multiple vertical field-of-view extensions

Special techniques for fan-beam CT with the LDA

Horizontal field-of-view extension, a Comet Yxlon patent unique in the market

Determination of regions of interest (ROI) to be scanned with different line pitches with effect on image quality and speed

Image quality optimizations

ScatterFix 2.0, e.g. for optimized surface determination

Beam hardening correction (BHC) to correct unwanted gray-value gradients

Metal artifact reduction (MAR) to minimize interfering effects which occur at complex components consisting of plastics and metals.

Technical data

| Sample Diameter | 600 [mm] |

| Sample Height | 850 [mm] Flat-Panel Detector / 800 [mm] Line Detector |

| System Dimensions (W/D/H) | 2,620 x 1,945 x 2,560 [mm] Flat-Panel Detector / 2,620 x 2,585 x 2,775 [mm] Line Detector |

| Maximum Sample Weight | 100 [kg] |

| X-ray Tube | 450 kV mini-focus |

| Detector Type | Flat-panel detector 4343 N and/or Comet Yxlon line detector CTScan 3 |

| CT Modes | Cone-beam CT, QuickScan, QualityScan, HeliExtend, SpeedMode, Fan-beam CT, ScanExtend (FoV extensions), Volume Crop |

| Voxel Size | Down to 55 [µm] |

| Inspection Envelope CT (3D) with Flat-Panel Detector | 570 x 850 [mm] |

| Inspection Envelope CT (3D) with Line Detector | 600 x 800 [mm] |

| Inspection Envelope DR (2D) | 520 x 850 [mm] |

| Manipulation | 5 axes |

Jacky

Jacky Jacky

Jacky