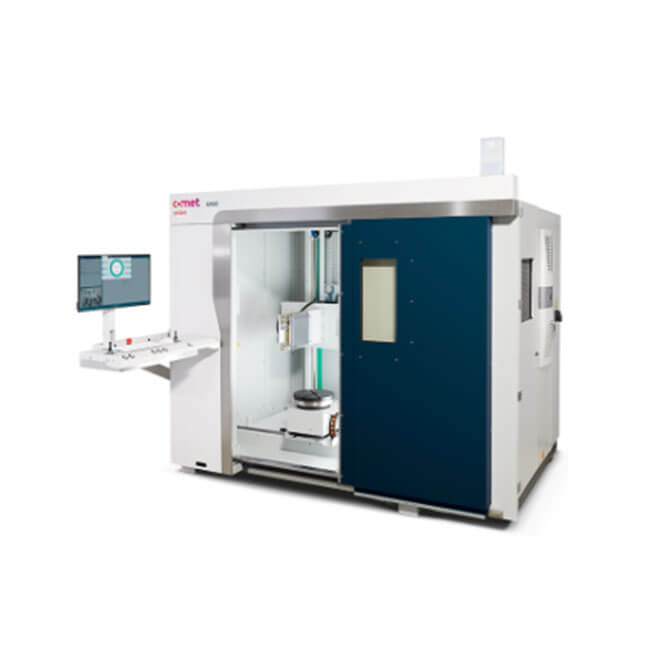

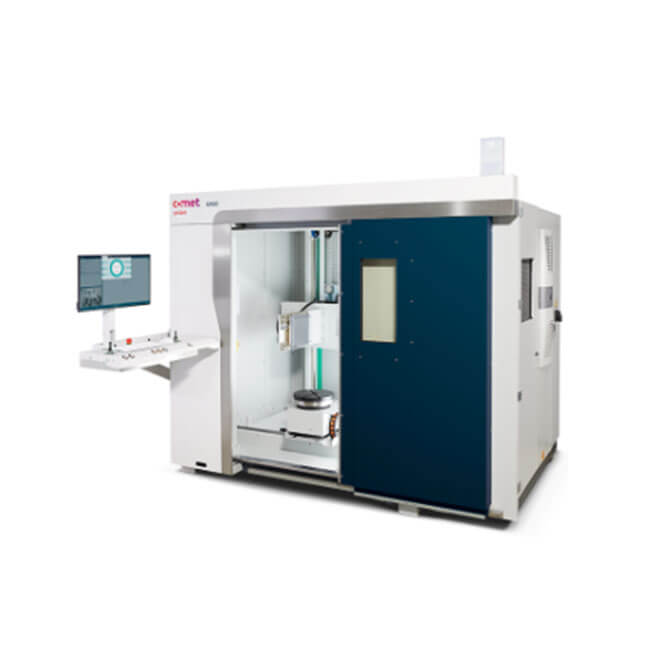

Yxlon UX20 SMT X-ray Inspection Machine

Designed to provide intuitive operation, the UX20 system makes it easy for users of all expertise levels to conduct highly efficient X-ray and CT inspections in record time - in manual, assisted or automated mode.

UX20 highlights:

Field-proven "Casting Insights" ADR software

Benchmark image quality

Fast results in 2D and 3D

Optional MesoFocus tube 225 kV

Image optimization with ScatterFix 2.0

Automated Data Transfer

SmartGuard crash protection

Compact footprint

Robust design

Effortless X-ray and CT inspection of cast parts

Due to the transformation to electric mobility, foundries are increasingly producing larger and more complex components. With its exceptional inspection envelope and our smart "Casting Insights" ADR packages, the UX20 facilitates fast and precise inspections of cast parts and helps increase overall production efficiency.

Casting Insights: Choose your automation level

Stay flexible and choose the level of automation that suits your production processes! Our new “Casting Insights” packages are built around our powerful, field-proven automated defect recognition (ADR) software TrueInspect. They enable reliable, fast and user-independent inspection decisions, in complete compliance with automotive requirements.

Your benefits with automated defect recognition (ADR)

Objective, reliable results

100% repeatability

Easy program teaching for new products

No false rejects

Increased yield

Enhanced productivity

Significant savings in time and costs

No product recalls

Significant savings in time and costs

See UX20 in our image gallery

Intuitive operation with Geminy

As the unique user interface for all workflows, Geminy makes x-ray and CT inspections as intuitive as possible. Diverse user roles help to streamline tasks: While the expert can tweak all parameters, less experienced operators will be guided through the workflow by wizards and presets.

Avoid collisions: SmartGuard

SmartGuard, a Geminy software wizard, helps to safely generate highly detailed images without the risk of collision when positioning the test part, especially when it comes to asymmetrical parts.

Keep track: part ID and part type

Track & trace capabilities provide the flexibility to add the ID/serial number of parts to the inspection data and reports manually or via a barcode scanner.

Simply share: Automated Data Transfer

Save time and effort in providing 2D and 3D inspection data such as images and reports by activating the Automated Data Transfer to a fileserver outside the system.

Stay informed: Healthmonitor

Operators can quickly analyze the system’s condition and performance with one look at the Healthmonitor.

The optimized image chain of the UX20 enables any operator to achieve reliable benchmark image quality.

ScanExtend: Enlarging the field of view

The UX20 is equipped with a strong suite of computed tomography features. With ScanExtend, the wizard guides users through the set-up of various scan-field extensions, while FlexCenter sets a virtual rotation axis to inspect difficult parts or regions of interest without the need to reposition the object.

With ScanExtend large parts can be inspected easily

ScatterFix 2.0: Optimized surface determination

ScatterFix 2.0 improves the quality of the CT data by reducing parasitic scattered radiation –for an optimized surface determination when inspecting large and massive components.

MesoFocus: Higher resolution, low maintenance

The MesoFocus technology combines the benefits of the mini-focus and the open micro-focus tubes. Three selectable focal spots provide optimum spatial resolution into the micro-focus range, while the robust design of a sealed tube makes the optional MesoFocus tube perfect for rough environments.

Which parts can be inspected with the UX20?

Automotive and aerospace castings

Welded structures

Multi-material components

Additive manufactured parts

Special alloys

Plastics and fiber-reinforced composites

Ceramics

Which applications is it designed for?

Quality assurance and material analyses

Failure analyses e.g., flaws, porosities, cracks, inclusions

Assembly checking

Measurements of inner structures

First inspections

Small series inspections

Spot-check inspections

Process control

Ergonomic design, no distractions

The clean layout of the operator desk allows users to stay focused on the inspection task. The height of the control panel can be adjusted to meet individual requirements to work in a standing or sitting position. The joysticks and buttons on the panel can also be operated when wearing gloves.

Height adjustable operator desk

Technical Data

| Configuration | Flat-panel detector 2323 HB | Flat-panel detector 4343 DXi |

| Maximum Sample Weight | 100 [kg] | 100 [kg] |

| System Dimensions | 2250 x 1770 x 2350 [mm] | 2250 x 1770 x 2350 [mm] |

| Available X-ray Tubes | 160-225 [kV] mini-focus, 225 kV MesoFocus | 160-225 [kV] mini-focus, 225 kV MesoFocus |

| Detector Active Area | 1280 x 1280 [px] | 3072 x 3072 [px] |

| Pixel Pitch | 179 [µm] | 139 [µm] |

| Oblique Viewing | +/-55 (45° in central beam) | +/-55 (45° in central beam) |

| CT Modes | Cone-beam CT, QuickScan, QualityScan, FlexCenter (virtual rotation axis), ZoomScan, SpeedMode, ScanExtend (FoV extensions) | Cone-beam CT, QuickScan, QualityScan, FlexCenter (virtual rotation axis), ZoomScan, SpeedMode, ScanExtend (FoV extensions) |

| Inspection Envelope DR (2D) | 710 x 1090 [mm] | 800 x 1100 [mm] |

| Inspection Envelope CT (3D) | 190 x 165 [mm] | 340 x 280 [mm] |

| Inspection Envelope CT (3D) with ScanExtend | 315 x 1085 [mm] | 540 x 1100 [mm] |

Jacky

Jacky Jacky

Jacky