Yxlon FF85 CT SMT X-ray Inspection Machine

With its dual-tube configuration, the high-energy, high-resolution FF85 CT achieves extremely precise inspection results for a wide variety of material types and part sizes.

FF85 CT highlights:

Extensive range of applications from microCT to high-energy CT due to dual tube configuration and both flat-panel and line detector

Large inspection envelope by diverse field-of-view extensions, helical and dual-helical CT techniques

Granite base for temperature stability and precise manipulation

Maximum versatility through up to 7 manipulation axes

Intuitive Geminy user interface with touchscreens for easy system operation

High energy. High resolution. High versatility.

Small parts or large parts, the optional combination of two X-ray tubes with a spacious flat-panel detector (DDA – digital detector array) and a linear detector array (LDA) caters to the broadest application range. While the mini-focus tube, with its high energy of up to 600 kV, is the right solution for large and dense parts, the directional micro-focus tube (up to 300 kV) provides detailed insights into the inner structures of small components. Seamless switches between 2D radioscopy, 3D cone-beam, and fan-beam CT provide outstanding flexibility and the creation of individual inspection processes.

See more of FF85 CT in the gallery:

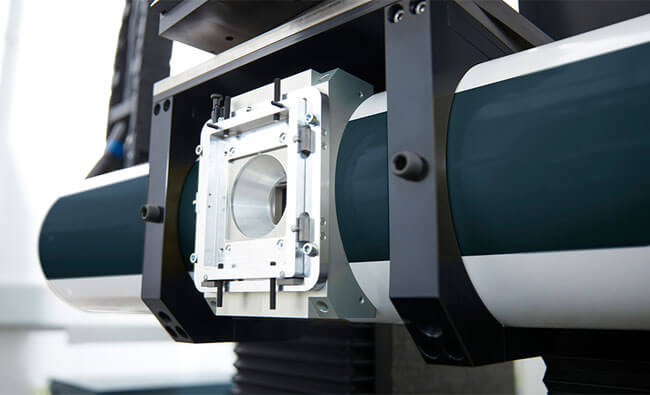

Comet Yxlon CTScan 3 line detector array

Comet Yxlon developed the CTScan 3 line detector array (LDA) for customers’ special requirements and challenging applications. With its unprecedented signal-to-noise ratio, its dynamic range, and a pixel pitch of 254 μm, it is the no-alternative solution for the crystal-clear inspection of large and/or dense components. It is designed for up to 600 kV operation reducing unwanted scatter radiation and providing low-noise electronics and highly efficient scintillators.

Comet Yxlon Line Detector CTScan 3

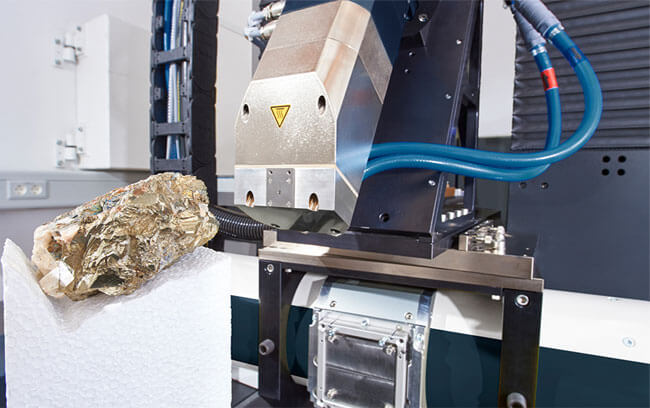

Almost indestructible: the granite-based manipulator

Another building block that contributes to the premium performance of FF85 CT is the rock-solid granite-based manipulator. It makes the system extremely precise and durable by providing warp resistance and temperature stability.

Various trajectories for maximum flexibility

Graphic symbols and a wide range of automated functions, displayed on the intuitive user interface Geminy make operation easy – regardless of the operator’s skill level. At the same time, it offers a great number of features for flexibility regarding part sizes and inspection tasks, like CT trajectories such as HeliExtend (helical CT scan and reconstruction method), horizontal and vertical field-of-view extensions, a virtual rotation axis, and standard quick/quality scans. Image enhancement tools like ScatterFix 2.0, beam hardening reduction (BHC), or metal artifact reduction (MAR) reduce or eliminate scattered radiation or artifacts in the image.

Which items can be inspected with the FF85 CT?

Aluminum, steel, and super alloy components

Additively manufactured parts

Battery cells, modules, and systems

Fiber-reinforced composites

Plastic injection molded parts

Cultural assets, historical art, and archeological objects

Geological, paleontological and biological samples

Mechatronic modules

Which applications is the FF85 CT designed for?

Material and structural analysis in research and development

First article inspection

Dimensional measurement

Small series inspection

Failure analysis

Assembly checks

Digitization

Segmentation

Technical Details

| Sample Diameter | 1000 [mm] |

| Sample Height | up to 1840 [mm] |

| Maximum Sample Weight | 400 [kg] |

| Focus-Detector-Distance (FDD) | up to 2050 [mm] |

| Available X-ray Tubes | 600 kV Minifocus |

| 450 kV Minifocus | |

| 450 kV Mesofocus | |

| 300 kV Microfocus | |

| 225 kV Microfocus | |

| 190 kV Nanofocus | |

| Available CT Modes | Cone-beam CT, QuickScan, QualityScan, HeliExtend, FlexCenter (virtual rotation axis), ZoomScan, LayerScan, SpeedMode, Fan-beam CT, ScanExtend (FoV extensions), Volume crop |

| Manipulation | 7 axes, granite base |

Jacky

Jacky Jacky

Jacky