Yamaha Z:LEX YSM20R Pick and place machine

Achieves both a whole new dimension of versatility and high-speed for mounters via the 1-head solution

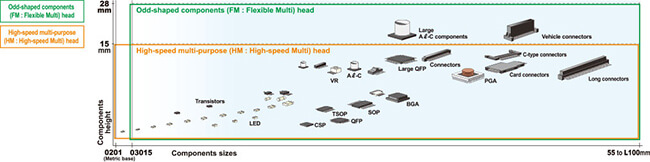

Two types of heads are available that bring the "1-head solution" to an even higher dimension capable of accommodating a wide range of components while maintaining high speed with no head replacement. High-speed general-purpose heads can be used for ultra-small (0201mm) chip components.

High-speed multi-purpose (HM : High-speed Multi) head

This universal type head made for high-speed mouuting and versatility supports from ultra-tiny chips of 0201mm to large-size components of 55 x 100 mm and height of 15 mm.

Odd-shaped components (FM : Flexible Multi) head

Super wide-ranging type head supports load control, and handles a broad spectrum of components from ultra-tiny chips of 03015mm, to ultra-large components of 55 x 100 mm and tall components of heights to 28 mm.

Superb mounting performance 95,000 CPH (under optimum conditions as defined by Yamaha Motor)

Improving mounter operation from component pickup to mounting and using high-speed XY axes achieved production of 95,000 CPH which is 5% higher than conventional models.

Huge improved adaptability to actual production

Mounting a new type wide-scan camera increases and expands recognition capability to support high speed mounting of components down to only □8 mm to □12 mm in size. Also, use of side lighting gives high-speed recognition of ball electrode components such as CSP (chip scale packages) and BGA (ball grid arrays).

Beam variations available in 2 types

Achieving a common platform allows selecting from 1-beam and 2-beam for configuring the X-axis according to production mode and mounting capability.

Wide support capability turns the concept of “Limitless EXpansion” into a reality!

Compatible components

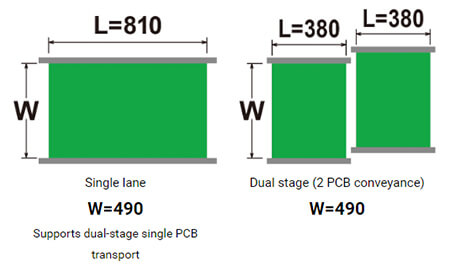

Conveyors available in freely configurable variations

Conveyor system is selectable from dual stage, single lane. Supports PCB sizes to a max.L810 x W490 mm (Dual stage, single lane for conveying single PCB). Single lane also available in M size specifications (max. PCB size L360 x W490 mm) having superior cost performance.

Numerous functions to support high-quality mounting are included as standard features.

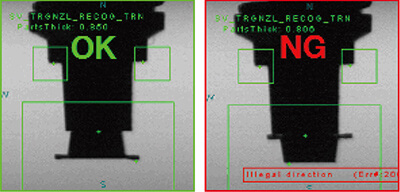

Side view function

Detects pickup status and component’s presenge with no downtime loss.

Blow station

Automatic blow cleaning function keeps nozzle clean for long periods.

High-speed smart recognition

Highly robust “High-speed Smart Recognition” that also creates recognition data for custom or unique components in a short time is now standard equipment.

Accumulation of all images (All Image Tracer)

Saves all of your mounter component recognition images on-time, and all the way through the production process yet with no stress. Gives powerful support for analyzing component mounting quality.

Achieves highly-streamlined components supply

sATS30NS Auto Tray Sequencer (ATS) for nonstop tray replacement

In addition to sATS30 and cATS10, automatic replaceable tray component feeders, sATS30NS which enables pallet replacement with automatic operation continued has been added to the product lineup. Supply of pallets to the magazine is complete just by setting new pallets in exchange for empty pallets that have been automatically ejected and pressing a button. It is possible to set magazines at once in the setup process, achieving a substantial reduction in trouble and loss regarding component supply.

Auto Loading Feeder

Tape components can be supplied just by inserting the tape without stopping the machine. The unique center open technique from Yamaha drastically reduces components pickup errors that occur from static electricity and the residue when peeled from the tape. No recovery of top tape is needed which vastly increases the operating rate.

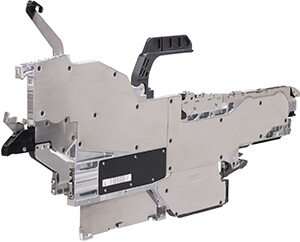

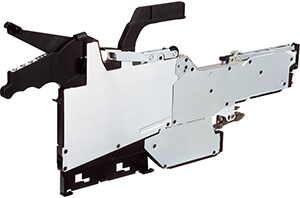

ZSR feeder

Super-slim, ultra-light electric intelligent feeder that realizes high workability and reduction of work burdens of operators. With its high durability, comfortable workability is supported without maintenance over an extended period of time.

| Model | YSM20R |

| Applicable PCB | Single lane |

| L810 x W490 to L50 x W50 | |

| Dual stage Note: For X-axis 2-beam option only | |

| 1PCB conveyance: L810 x W490 to L50 x W50 | |

| 2PCB conveyance: L380 x W490 to L50 x W50 | |

| Head / Applicable components | High-Speed Multi (HM) Head * |

| 0201mm to W55 x L100mm, Height 15mm or less | |

| Odd-shaped components (FM: Flexible Multi) head: | |

| 03015mm to W55 x L100mm, Height 28mm or less | |

| Mounting capability | X axis 2-beam: High-speed multi-purpose |

| (under optimum conditions as defined by Yamaha Motor) | (HM: High-speed Multi) head x 2 |

| 95,000CPH | |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) |

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder) |

| Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) | |

| Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) | |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L 1,374 x W 1,857 x H1,445mm (Main unit only) |

| Weight | Approx. 2,050kg (Main unit only) |

Specifications and appearance are subject to change without prior notice.

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky