VISCOM iX7059 PCB 3D AXI SMT X-ray Inspection Machine

iX7059 PCB Inspection – 3D X-ray inspection for high-density and double-sided PCB assemblies at the highest level

With its iX7059 product line, Viscom is setting a new standard for high-precision inline X-ray inspection of printed circuit boards. Outstanding inspection performance for SMD and THT solder joints as well as exact measurement of voids deliver 100% quality assurance in modern SMT production, so that hidden defects can be detected even when complex assemblies cause massive shadowing effects. In addition to traditional SMD inspection, the compact iX7059 PCB Inspection or iX7059 PCB Inspection XL 3D AXI system also provides high-precision, reliable inspection of soldering defects such as head-in-pillow and pores in BGA and LGA components. Cutting-edge, powerful microfocus X-ray technology, new dynamic 3D image acquisition methods and seamless handling guarantee the best throughput rates. The iX7059 PCB Inspection XL with extended longboard option comes into play for especially large PCB assemblies measuring up to 1,400 mm – this solution is ideal for server boards, LEDs, semiconductors and 5G electronics.

Advantages at a glance

Optimal FPY results in SMT production

Future-ready 3D inline X-ray with CT

Inspection even for large PCB assemblies

Best defect coverage for zero defect strategy

Space-saving system design

Extremely simple programming

Inspection Scope

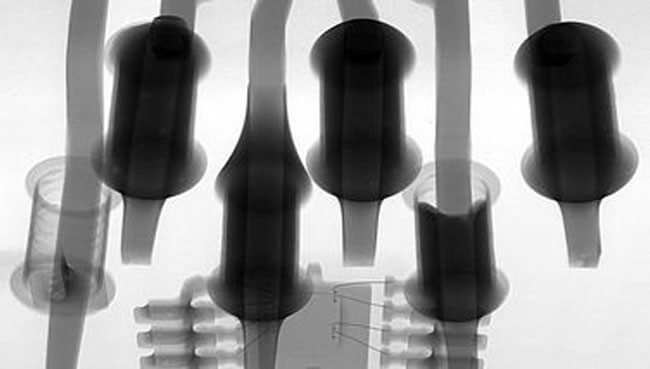

THT solder joint, good/poor, insufficient degree of filling

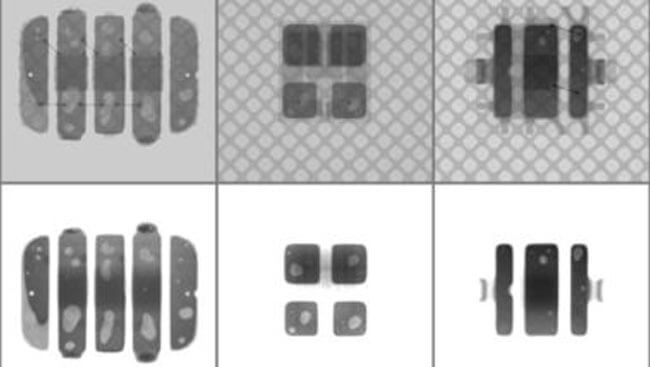

Comparison of 2D AXI and 3D AXI slice images of different LEDs

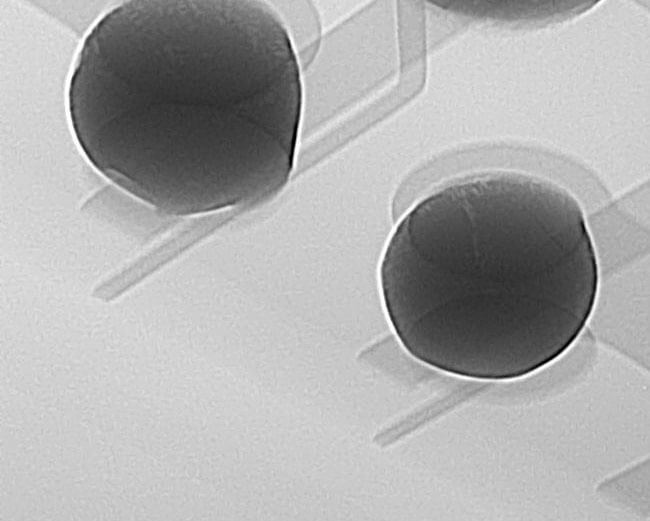

Head in pillow defect

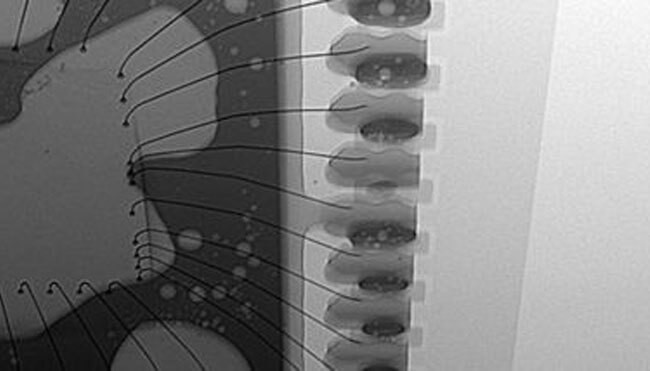

Poor QFN, insufficient solder volume

HIGHLIGHTS

Seamless, perfect handling of PCB assemblies – even for very large PCBs measuring up to 1,400 mm

Powerful X-rays with 130 kV or optionally 160 kV

Unbeatably fast dynamic image acquisition concept Evolution 4 or optionally 5 for even more speed and the highest throughput

High-precision inspection in 2D, 2.5D and 3D

High-quality 3D AXI volume calculation with planar CT

Additional vertical slices for optimum analyses and dependable verification

Fast inspection program creation thanks to 3D analysis and an IPC-compliant AXI inspection library

Maximum inspection program optimization through integrated verification

CONNECTIVITY

Global libraries, global calibration: transferability to all systems

Automated grayscale value calibration for consistent inspection results

Traceability, statistical process control, offline programming, multiline verification

Viscom Quality Uplink: effective networking and process optimization

Interfaces: SMEMA, IPC Hermes Standard (optional)

INSPECTION

Scope of inspection:

Air inclusions/blow holes (voids) in surface soldering, presence, offset, excessive/insufficient solder, solder bridge, solder balls, solder sputter, soldering defects, THT fill level and pin height, nonwetting, contamination, damaged component, missing or incorrect component, imperfect shape, tombstoning, lifted lead, billboarding, supine, twist, wick-up effect (optional)

Jacky

Jacky Jacky

Jacky