VISCOM iX7059 Device 3D AXI SMT X-ray Inspection Machine

iX7059 Device Inspection – Innovative X-ray inspection for maximum product quality and process efficiency

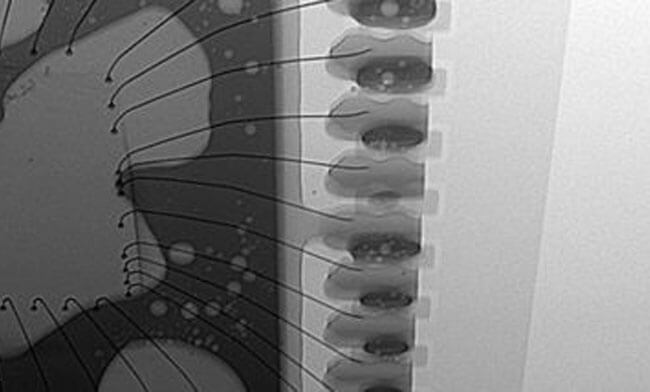

The iX7059 Device Inspection X-ray system offers a cost-effective solution for fast and reliable final inspection across a wide range of devices and applications that demand flawless, day-to-day functionality. Its versatility supports inspection of products including smartphones, tablets, notebooks and desktop PCs to smart watches, earphones, Smartglasses, ring scanners, cartridges, braizings, RFID wristbands and hearing aids.

Whether in the production line or as a stand-alone unit, the system identifies hidden faults such as foreign objects that can lead to short circuits or missing components that may later impair functionality. The robust and maintenance-friendly design of the iX7059 Device Inspection allows 24-hour operation, ensuring short cycle times and a large inspection depth guarantee compliance with high quality standards with maximum productivity.

Seamless networking with other Viscom systems enhances process control. Viscom offers powerful tools for statistical monitoring and documentation of the production steps, enabling insightful analysis of inspection results. The inspection programs can be quickly created and optimized with ease, an advantage for adapting to frequent product changes.

Advantages at a glance

Options for targeted oblique radiation (2.5D)

3D X-ray system

Networking with other Viscom systems

24-hour opertion

Inspection Scope

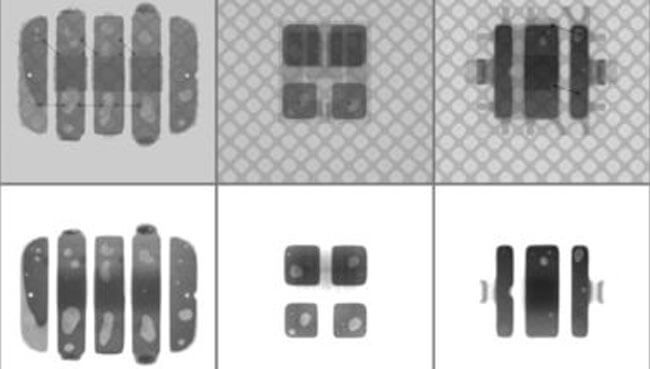

Comparison of 2D AXI and 3D AXI slice images of different LEDs

Poor QFN, insufficient solder volume

HIGHLIGHTS

Seamless, perfect handling of PCB assemblies – even for very large PCBs measuring up to 1,600 mm

Powerful X-rays with 130 kV or optionally 180 kV

High-precision inspection in 2D, 2.5D and 3D

High-quality 3D AXI volume calculation with planar CT

Additional vertical slices for optimum analyses and dependable verification

CONNECTIVITY

Global libraries, global calibration: transferability to all systems

Automated grayscale value calibration for consistent inspection results

Traceability, statistical process control, offline programming, multiline verification

Viscom Quality Uplink: effective networking and process optimization

Interfaces: SMEMA, IPC Hermes Standard (optional)

INSPECTION

Scope of inspection:

Air inclusions/blow holes (voids) in surface soldering, presence, offset, excessive/insufficient solder, solder bridge, solder balls, solder sputter, soldering defects, THT fill level and pin height, nonwetting, contamination, damaged component, missing or incorrect component, imperfect shape, tombstoning, lifted lead, billboarding, supine, twist, wick-up effect (optional)

Jacky

Jacky Jacky

Jacky