VISCOM iX7059 Heavy Duty 3D SXI SMT X-ray Inspection Machine

iX7059 Heavy Duty Inspection – fast inline inspection with maximum precision

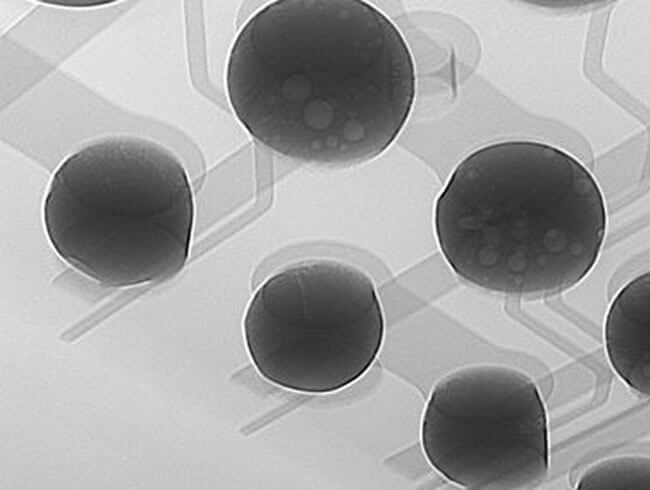

Large, heavy, and solid assemblies – whether encased or as complete models – require 100% quality assurance, depending on the area of application. As a result, perfect-fit inline X-ray inspection in 2D, 2.5D, or 3D is the first choice for high current and high voltage electronics. This is because inspected components and flawless solder joints are the only way to guarantee the necessary functional reliability in cases where, for example, critical solder joints that have air inclusions of an excessive number or size could jeopardize heat dissipation in power electronics and lead to overheating. With its iX7059 product line, Viscom is setting a new standard for fast, high-precision inline X-ray inspection. The special transport system enables seamless handling of inspection objects on workpiece carriers or in soldering frames with a weight of up to 40 kg – a unique feature that offers huge advantages for trending segments such as e-mobility, new energies, and telecommunications.

ADVANTAGES AT A GLANCE

100% quality assurance

Future-ready inline X-ray

Fast inspection of heavy electronics

Space-saving system design

Also ideal for the final assembly line

Rapid delivery times

Inspection Scope

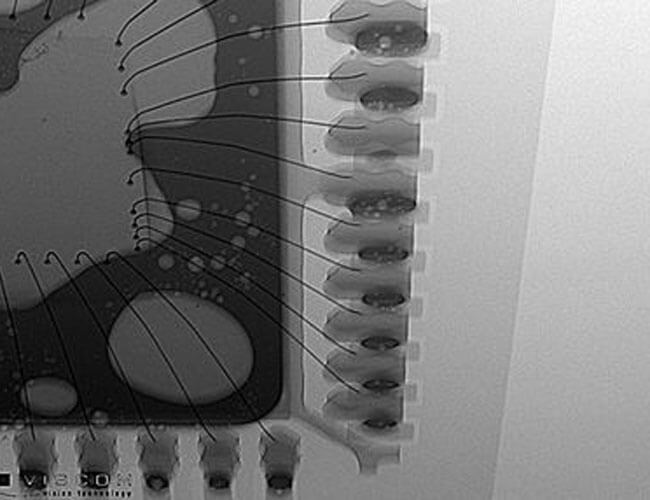

Poor QFN, insufficient solder volume

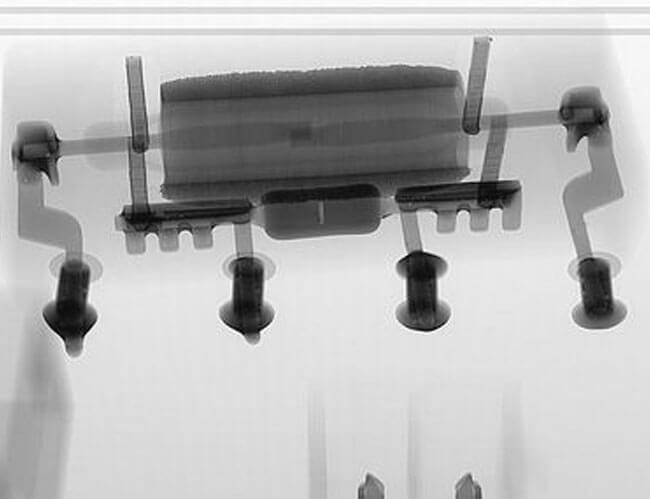

Poor THT solder joint, insufficient degree of filling

Poor THT solder joint, good and bad degree of filling

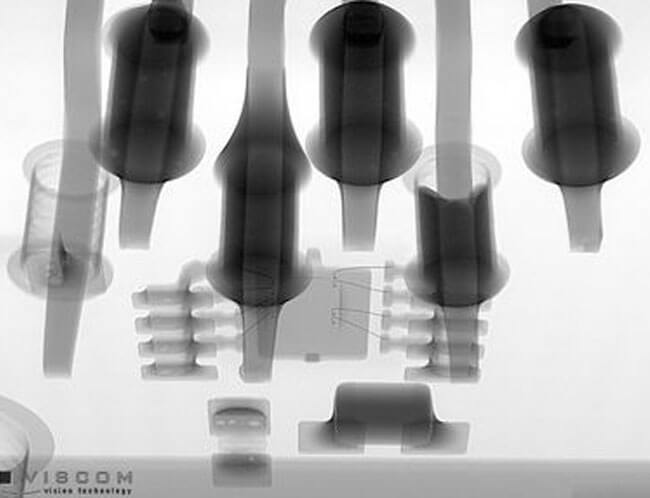

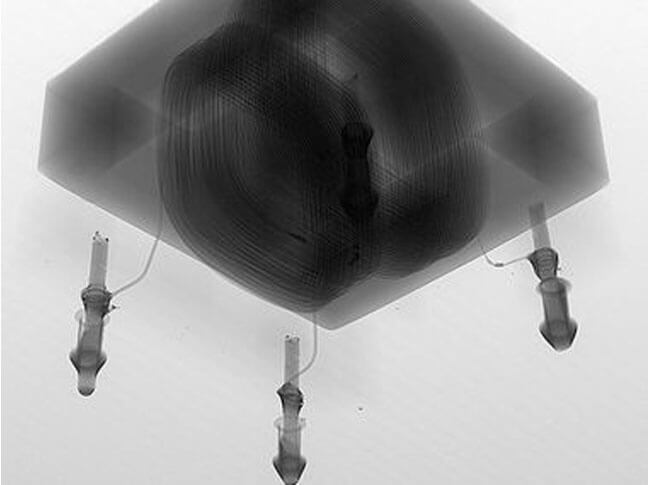

Transformer including THT terminals with varying fill levels

[Translate to Asia English:] Coil with good and bad THT solder joints

Lower solder ball set not on solder paste pad

HIGHLIGHTS

Reliable inspection for heavy, solid, and encased components

Powerful X-rays with 130 kV or optionally 160 kV

One-of-a-kind transport concept for fast handling of workpiece carriers and soldering frames

High-precision inspection in 2D, 2.5D, and 3D

Fast inspection program creation thanks to 3D analysis and an IPC-compliant AXI inspection library

Maximum inspection program optimization through integrated verification

Additional vertical slices for optimum analyses and dependable verification

High-quality 3D AXI volume calculation with planar CT

CONNECTIVITY

Global libraries, global calibration: transferability to all systems

Automated grayscale value calibration for consistent inspection results

Traceability, statistical process control, offline programming, multiline verification

Viscom Quality Uplink: effective networking and process optimization

Interfaces: SMEMA, IPC Hermes Standard (optional)

INSPECTION

Scope of inspection: Air inclusions/blow holes (voids) in surface soldering, presence, offset, excessive/insufficient solder, solder bridge, solder balls, solder sputter, soldering defects, THT fill level and pin height, nonwetting, contamination, damaged component, missing or incorrect component, imperfect shape, tombstoning, lifted lead, billboarding, supine, twist, wick-up effect (optional)

Jacky

Jacky Jacky

Jacky