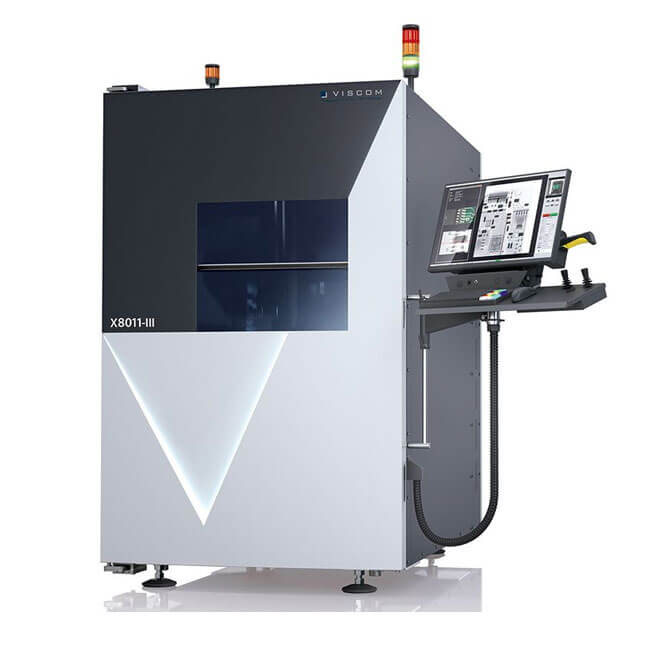

VISCOM X8011-III 2D and 3D SMT X-ray Inspection Machine

The Viscom X-ray system X8011-III is designed as a team player for individual and reliable use for 2D and 3D X-ray inspection. Thanks to its innovative and simple system operation, the system can be used for manual and automatic X-ray inspection of components, assemblies during production, quality assurance and development – thereby making a sustainable and result-oriented contribution to cost optimization, process reliability and increased product quality. High-quality system components, maximum flexibility through the use of interchangeable modules for perfect specimen handling, as well as simple and intuitive system operation with the option of rapid inspection program creation through to automatic results documentation in the form of professional reports with radiation dose information for X-ray inspection are just some of the highlights of the new X8011-III. Yet more features: the X8011-III X-ray system can be integrated into the production line and intelligently networked with other systems to optimize the manufacturing process.

ADVANTAGES AT A GLANCE

Practice-oriented, proven system concept

Extensive system options and extensions

Intuitive system operation

High resolution and excellent image quality

Automatic, personalized documentation of test results

Information on radiation dose during X-ray inspection

High target power of 40 W – open microfocus X-ray tube

Universal, flexible exchangeable module for perfect sample handling

Suitable for high-mix, low-volume manufacturing

Inspection Scope

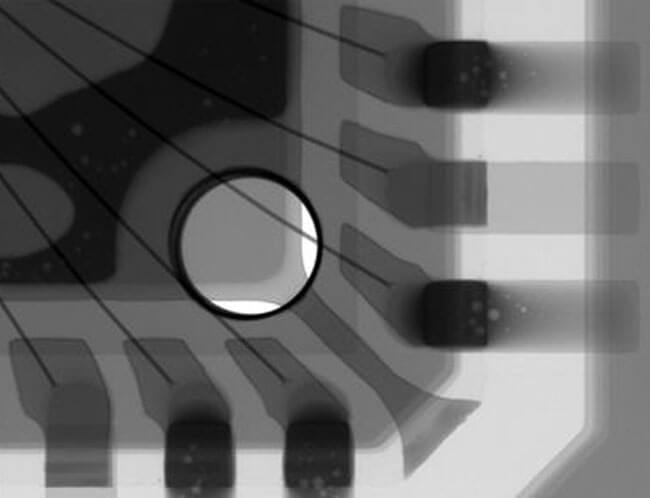

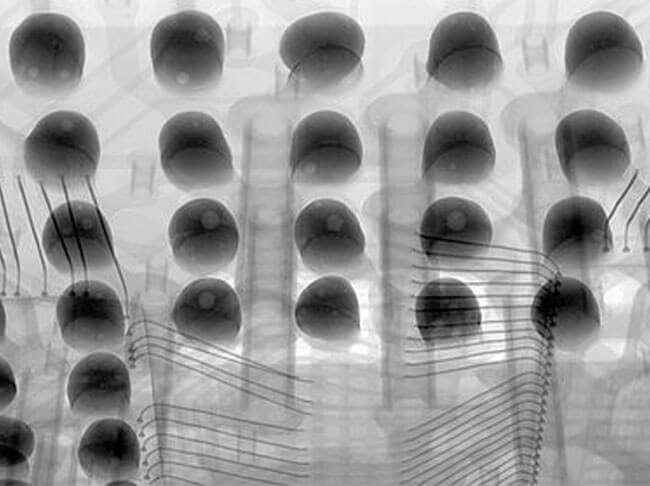

Partial view of a QFN

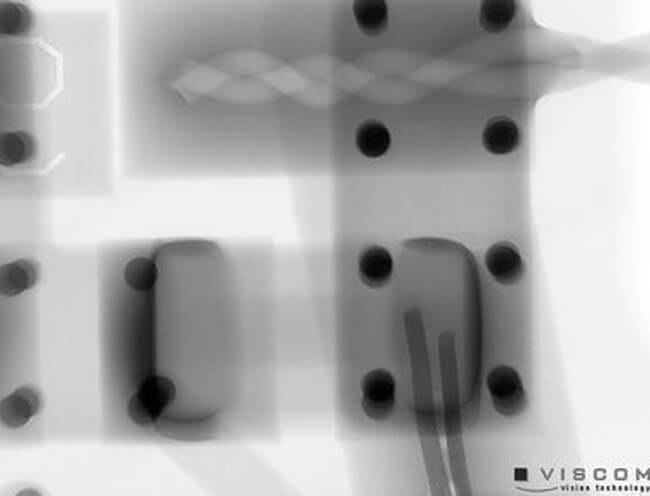

Detail of a medical product

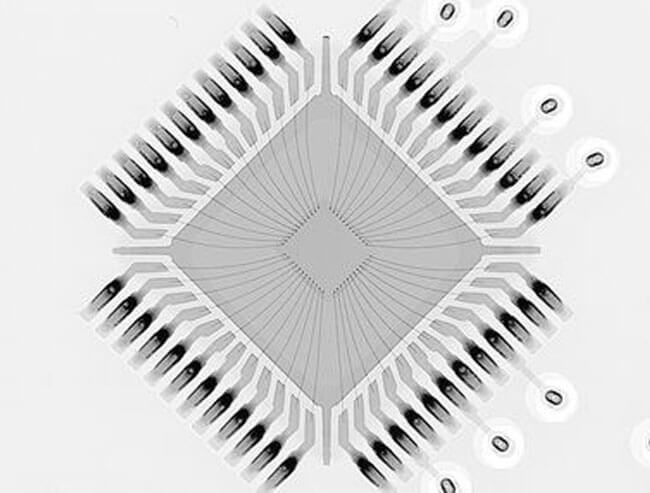

Chip component with orthogonal radiation

BGA with partially defective solder joints

HIGHLIGHTS

Simple system operation

Fully manual or inline-compatible inspection mode

Quick, easy inspection program creation

Leading X-ray solutions for inline and offline X-rays

A flexible system configuration of all Viscom X-ray tubes up to 200kV

Optimum magnification and high-end image quality

The use of high-resolution, digital flat-screen detectors

Rapid axis and module change via EasyClick method

Upgradable with Viscom-native computed tomography

Reliable inspection in 2D and 3D in the shortest cycle time

Intuitive user interface for manual and automatic use

Upgradable for future inspection tasks due to the modular system design

CONNECTIVITY

Use of high-quality system components

Automated software analyses and inspection programs

Customer-specific software adaptations

Robust inspection strategies using the Viscom standard library

Independent real-time image processing with Viscom analysis tools

Verification station Viscom HARAN

Viscom Quality Uplink to AOI, AXI, and SPI for cost optimization and process reliability

Maximum system uptime thanks to individual service concepts

INSPECTION

Components: Electronic components and SMT components (BGA, μBGA, flip chips, and assembled circuit boards)

Solder joints: Visible and concealed solder joints

Defects/defect features: Air inclusions/blow holes in the solder joint (voids), presence, offset, too much/insufficient solder, solder bridge, solder balls, solder sputter (optional), soldering defects, non-wetting, contamination, damaged component, missing or incorrect component, imperfect shape, tombstoning, lifted lead, billboarding, supine, twist, polarity error, wick-up effect (optional), head-in-pillow (balls), THT fill level and pin height

Jacky

Jacky Jacky

Jacky