VISCOM X7056-II 3D AXI 3D AOI SMT X-ray Inspection Machine

X7056-II – An Innovative Inline X-ray System

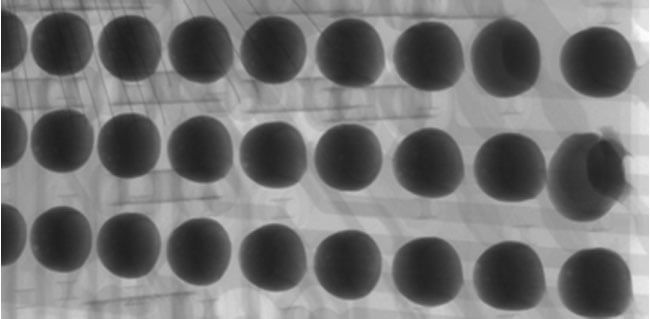

The X7056-II's state-of-the-art X-ray technology ensures precise inspection of high-end electronics. The inline X-ray system has won five international awards for its extremely high throughput and outstanding image quality. Even concealed solder joints and components are displayed as crystal-clear slice images to guarantee seamless quality control. The option to also integrate AOI inspection within the system and to perform combined inspections is a special feature of the X7056-II – an efficient, space-saving highlight that provides fast and comprehensive inspection results.

ADVANTAGES AT A GLANCE

Maximum inspection result stability

Ultra-fast inspection times

Maximum flexibility

Combined AOI/AXI saves space

Long-term investment security

Inspection scope

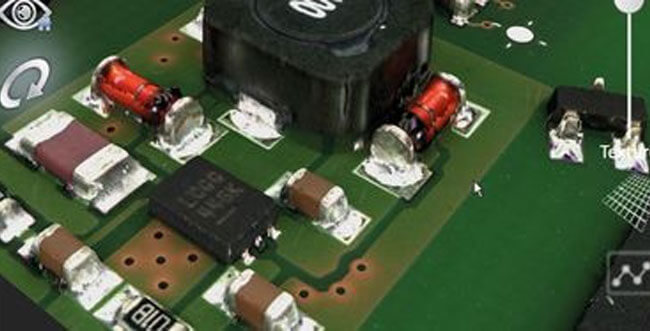

3D AOI view in the AOI/AXI combined inspection

Surface soldering with voids

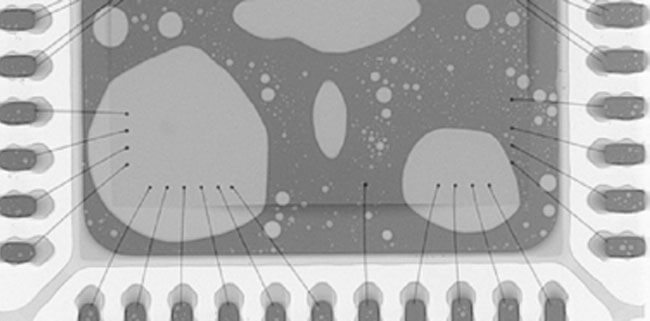

Head-in-Pillow defect on BGA component

HIGHLIGHTS

System can be used as a 3D AXI system or combined 3D AXI / 3D AOI

Revolutionary xFastFlow handling concept for changing printed circuit boards in as little as 4 seconds

Ultra-thorough inspection of single or double-sided electronic assemblies

Three different flat panel detector sizes for scalable throughput

Fast inspection program creation thanks to 3D analysis and an IPC-compliant AXI inspection library

Maximum inspection program optimization through integrated verification

Additional vertical slices for optimum analyses and dependable verification

High-quality 3D AXI volume calculation with planar CT

CONNECTIVITY

Global libraries, global calibration: Transferability to all systems

Automated grayscale value calibration for consistent inspection results

Traceability, statistical process control, offline programming, multiline verification

Viscom Quality Uplink: Effective networking and process optimization

Optional:

Freely configurable interfaces for connecting various modules

Control of label printers, bad-board markers and FIFO buffers

Communication with MES systems

Support for M2M communication standards such as SMEMA, IPC-CFX,

The Hermes Standard, and JARAS 1014

INSPECTION

Components: BGA up to 0.3 mm pitch, QFN, DFN, LGA, THT/THR, LEDs

Solder joints: Visible and concealed solder joints

Defects/Features: Air inclusions/blow holes in solder joints (voids), presence, misalignment, excessive/insufficient solder, bridging, solder balls, solder sputter (optional), soldering defects, nonwetting, contamination, damaged component, missing or incorrect component, imperfect shape, tombstoning, lifted leads, billboarding, face down, rotation, polarity, solder wicking (optional), head-in-pillow (balls), THT filling degree and pin height

Combined AOI/AXI: character recognition, color recognition, barcode recognition, OCR (optional), analysis of free surfaces (optional)

Jacky

Jacky Jacky

Jacky