UNICOMP LX9200 SMT X-ray Inspection Machine

Unicomp Technology 3D Inline X-ray Inspection Equipment——LX9200

As a new generation of upgraded and optimized LX9200 online inspection equipment, it can easily meet the multi-directional and multi-angle product inspection needs of different users.

Application Field

Function Features

Off line programming , realtime program modification

In-line Automated X-Ray , inspection System

Repair Station , barcode reading+realtime display

Server , Database&SPC&MES

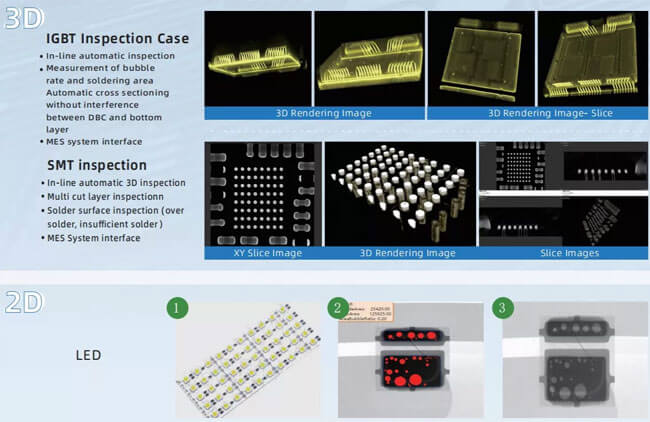

Inspection images

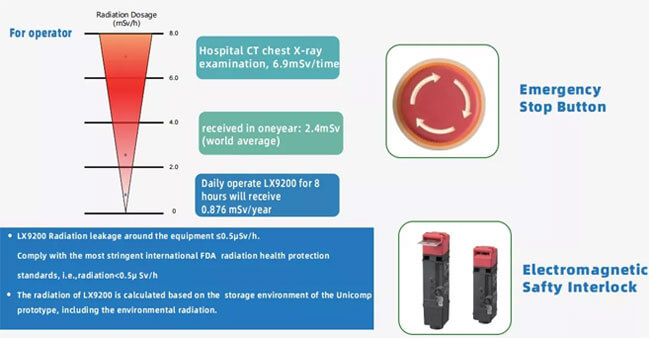

Safety Protection

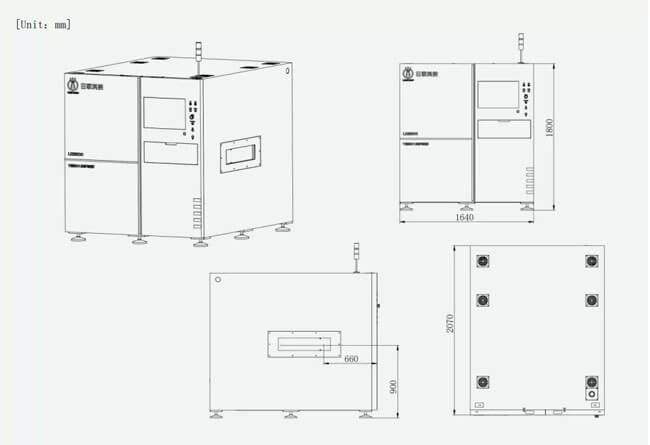

Dimensions and Appearance

Technical Parameters and Specifications

| Imaging system | |

| Imaging method | 2D, 2.5D, 3D (All in one) |

| X-ray source | Sealed tube (Max.130kv / 65w) |

| Detector | High resolution FPD (flat panel detector) |

| Image Resolution | 9um,12um,18um,24um,30um (option 3um or 6um) |

| Camera | CCD camera |

| Main Body | |

| Power supply voltage | 110-220V |

| Power supply frequency | 50/60HZ |

| Air pressure, capacity | 0.4~0.6Mpa |

| Dimensions | 1640mm(W) x 2070mm(D) x 1800mm(H) |

| Weight | 3710Kg |

| Motion | High speed smooth flying capture(High precision linear motor + linear encoder |

| CT mode | Planar CT |

| PCBA | |

| Conveyor height | 900±50mm |

| Inspection Area | 3D: 510mm X 670 mm ; 2D: 510mm X 730mm |

| Weight | max. 2kg (option:5kg) |

| Clearance | Top: 70mm ; Bottom : 40mm@30um |

| Application | |

| Inspection object | BGA, CSP, SOP, QFP, QFN, POP, inserted components, chips, T/H, Press-fit CN, IGBT, etc. |

| Inspection Items | Missing, misalignment, void, open, non-wet, shifting, foreign object, bridging, tombstone, insufficient / excess solder, solder ball, wrong polarity etc. |

Jacky

Jacky Jacky

Jacky