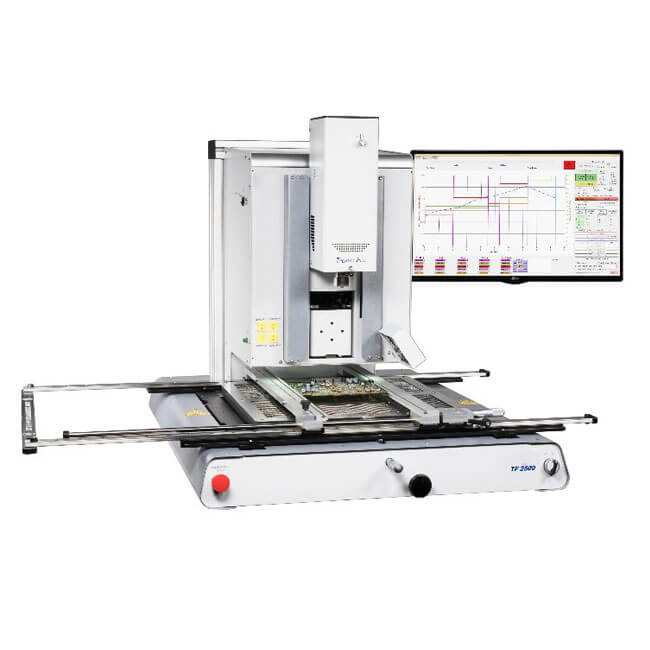

TF2800 BGA and SMD Rework System

Conventional resistance coil heating technology has been successfully used in convective rework stations for decades to install and remove a variety of BGA, QFN, CSP, CGA, PoP, Flip Chip, 0201 and other bottom terminated components. However, today’s extremely high thermal mass boards, ultra-fine pitch components and challenging production rework environments demand greater process control, thermal performance and faster throughput than ever before.

Enter PACE’s TF 2800 BGA/SMD Rework System. With its groundbreaking, patented Inductive-Convection Heating Technology, the TF 2800’s top-side heater reaches the target temperature in just seconds for safe, rapid solder joint reflow in virtually any component installation or removal application.

Features

Ultra-Precise 28µm Placement Accuracy

Revolutionary Inductive-Convection Heater

Active Cooling Through Nozzle Provides Rapid Solder Cooldown

4 Thermocouple Inputs

Adjustable Height Bottom-Side IR Preheater

Board Support Beam

Precision 24" x 24" PCB Holder

Auxiliary Cooling Fan

Motorized, High-Def (1080p) Optical Alignment System with Quad-Field Imaging

Single-Axis Operation

Windows 10 Micro PC with 24" LCB Monitor

Operator-Friendly Software Suite

Made in the USA

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky