TF1800 BGA and SMD Rework System

Conventional resistance coil heating technology has been successfully used in convective rework stations for decades to install and remove a variety of BGA, QFN, CSP, CGA, PoP, Flip Chip, 0201 and other bottom terminated components. However, today’s extremely high thermal mass boards, ultra-fine pitch components and challenging production rework environments demand greater process control, thermal performance and faster throughput than ever before.

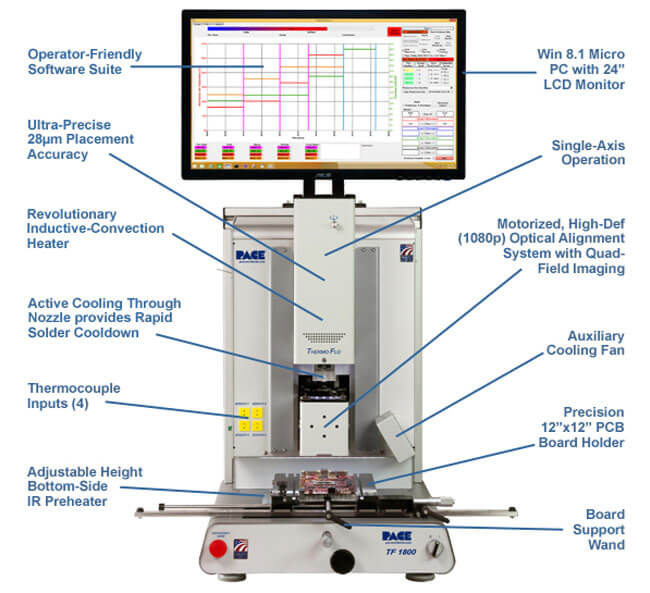

Enter PACE’s TF 1800 BGA/SMD Rework System. With its groundbreaking, patented Inductive-Convection Heating Technology, the TF 1800’s top-side heater reaches the target temperature in just seconds for safe, rapid solder joint reflow in virtually any component installation or removal application.

Top-Side Heater: Fast Heat Up - Rapid Cool Down

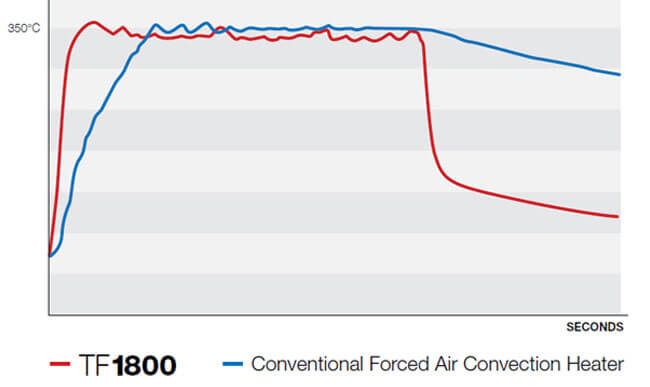

PACE’s Inductive-Convection Heater easily outperforms competitive heaters which utilize standard forced air convection technology, achieving target temperature instantaneously, about 4x faster than competitive heaters. Unlike conventional heaters, the TF 1800 immediately drops to temperatures well below solder melt when the heater is de-energized (results shown for TF 1800 Heater).

How Inductive-Convection Heating Works

The TF 1800’s patented Inductive-Convection Heating Technology provides ultimate thermal performance by its ability to instantly heat up and cool down the temperature of the air it delivers to the work.

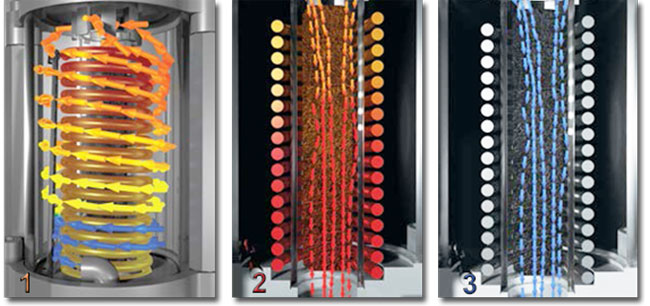

1.) The air is first pre-heated in the outer heater chamber as it moves in a cyclonic fashion around the induction coil before it enters the inner chamber. 2.) After entering the inner chamber, the pre-heated air is then heated to target temperature through a highly efficient heat transfer process in an energized induction field. 3.) During active cooling, the induction coil is de-energized and the TF 1800 delivers fast, controlled, active cooling of the component and PCB directly through the nozzle, eliminating the risk of excessive intermetallic growth and yielding the highest quality solder joints.

Powerful, Energy Efficient Performance

The TF 1800’s Inductive-Convection Heating Technology delivers all the power you need to tackle the most challenging high thermal mass PCBs available today. Yet, its highly-efficient design does it with just a fraction of the power required by yesterday’s conventional heating technology.

Advanced Features

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky