Nordson MXI Jade Plus SMT X-ray Inspection Machine

Overview

Restrictions in manufacturing materials and ever increasing expectations for reliability mean ensuring quality product manufacture is more important than ever. Jade Plus enables you to Prove Your Quality and reduce product returns from the field, and the associated cost and damage to reputation.

Prove Your Quality

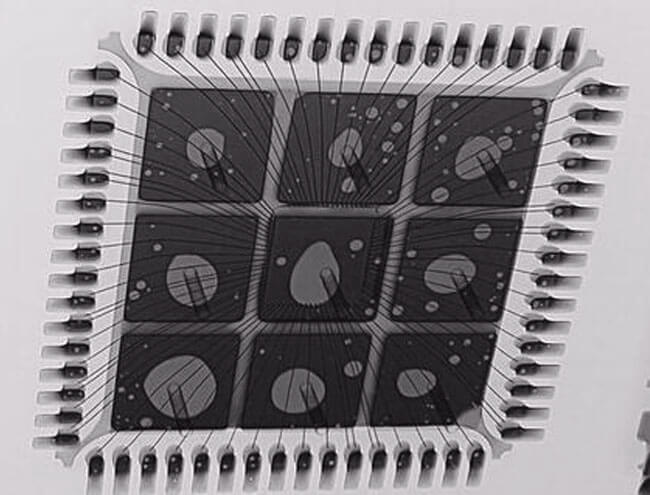

Jade Plus inspects the hidden regions of your products which are inaccessible to optical tools.

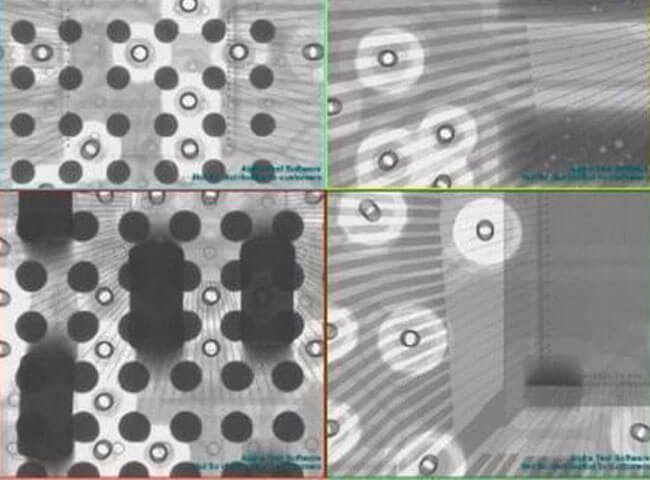

Spot quality process trends early using advanced measurement tools for distance measurement and voiding.

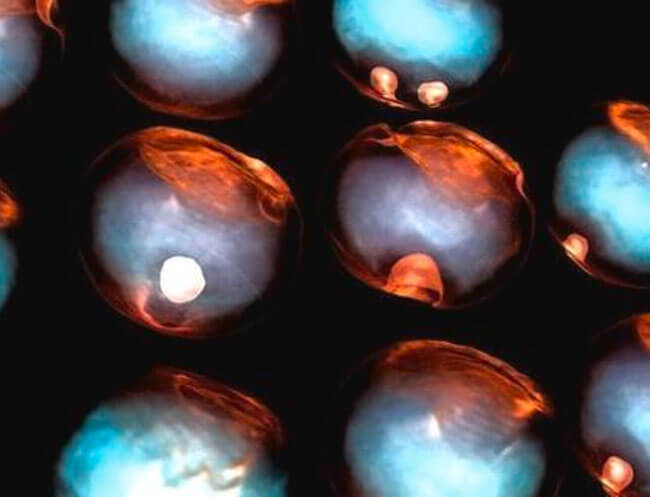

Ensure IPC-A-610 and IPC-7095 compliance with built in checking for BGA and QFN voiding, solder ball diameter, roundness, bridge and missing.

See assembly defects clearly with 0.95 µm image resolution.

Screen for solder pad defects quickly with automated voiding measurement.

See what you are inspecting and move to parts quickly with the Component Location feature.

Prove Your Quality

Measurement

Jade Plus gives a unique insight into your product quality. Advanced measurement functions, included as standard, turn X-ray images into quantitative data that you can use to spot emerging quality trends early, before it’s too late.

Compliance

In-built tools for dimension measurement, BGA void analysis, bump diameter and roundness and through hole filling make quick work of finding and characterizing defects, helping you achieve IPC-A-610 and IPC-7095 compliance.

Advanced Technology

Fast Throughput

Enjoy high throughput even with a high mix of products.

Save time inspecting multiple boards. Program an automated inspection routine once, then load, click and go.

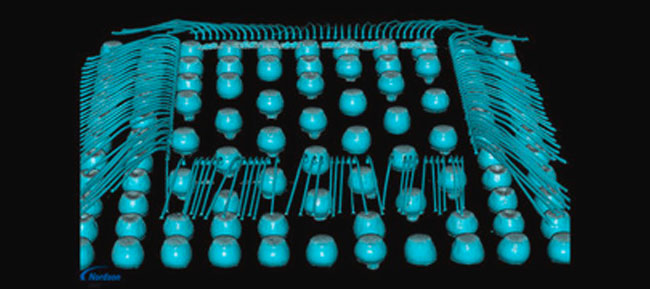

See from every side at high magnification. Nordson DAGE’s unique double angle geometry does not rotate the board so you never lose orientation.

Click to jump directly to a specific part. Component Location uses board design data so you always know what you are looking at.

Open Tube Technology

Jade Plus features an open X-ray tube with a replaceable tungsten filament.

Designed with maintenance in mind so you can be up and running fast, whenever the filament defocuses or expires.

Tungsten filaments fade over time, however you can experience ‘as new’ performance at any time by swapping in a new filament.

Training included, to minimize the risks of contaminating or damaging the X-ray tube during filament changes.

For a maintenance free alternative, consider Quadra® 3 which requires no filament changes, ensuring ‘as new’ uninterrupted performance for life.

Never loose your way

To prove your quality with confidence you need the highest quality tools.

Easy Navigation

See what you are inspecting and move to parts quickly with the Component Location feature.

Automated Inspection Routines

See what you are inspecting and move to parts quickly with the Component Location feature.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky