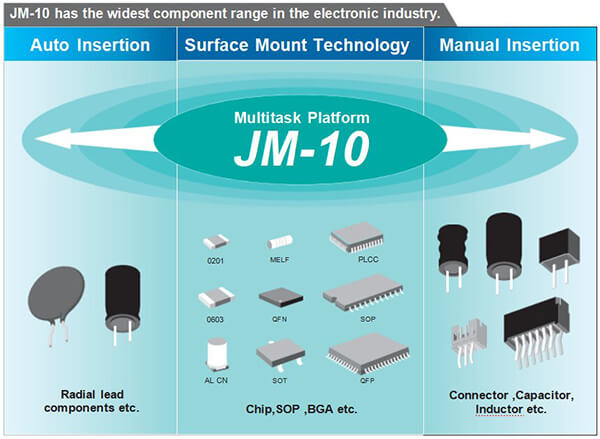

JUKI JM-10 Automatic Insertion Machine

Introducing the JM-10,the world's first multi-task platform.

The JM-10 is a revolutionary new concept from JUKI that allows the placement or insertion of both surface mount and through-hole components.

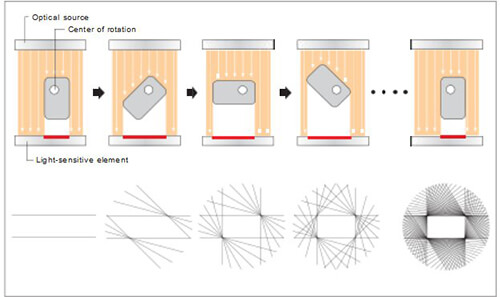

- Component centering using laser

Components are rotated 360 degrees in the laser. The entire outline of the component is measured accurately by a high resolution CCD sensor. The exact component position and angle are obtained in a fraction of a second without a side trip to a camera. Laser recognition can be performed from 0201 up to 33.5 x 33.5 mm.

- Simplified Data Entry

Simple data entry and fast, accurate lead-based component centering is accomplished using Laser Align.

Insertion lead part recognition.

Component handling and feeders

Bowl Feeder (MBF)

Vibratory bowl feeders are avail- able for bulk components.

Each feeder can hold up to six different components.

Two feeders can be mounted on each machine for a maximum of 12 different bulk components.

Radial Feeder (MRF-S / MRF-L)

For taped components, radial feeders are available.

The radial feeder cuts the leads and presents the components accurately for pick up.

Up to 10 feeders with MRF-S, 7 feeders MRF-L can be mounted both on the front and rear sides of the JM-10.

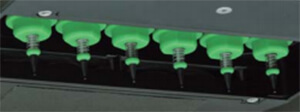

Standard equipped with 6 nozzles

The standard placement head has 6 nozzles and laser centering. A variety of common nozzle types also are included, and a vast assortment of specialized and custom nozzles are available for unusual components. Please consult your local JUKI representative regarding the production of special order nozzles to match components.

| MODEL | JM-10 | ||

| Board size | min. 50 x 50 mm / max. 410 x 250 mm | ||

| Component height | 28mm (component body 25mm + lead length 3mm) | ||

| Component size | Laser recognition | 0201 to 33.5 x 33.5 mm | |

| Placement speed | Pickup nozzle (optimum)*1 | 0.8 sec./component | |

| Gripper nozzle (optimum)*1 | 1.3 sec./component | ||

| Number of component to be attached | Bowl feeder | max. 12 types | |

| Radial feeder (MRF-S) | max. 20 types | ||

| Radial feeder (MRF-L) | max. 14 types | ||

| Board size | min. 50 x 50 mm / max. 410 x 250 mm | ||

| Component height | 25 mm | ||

| Component size | Laser recognition | 0201 to 33.5 x 33.5 mm | |

| Vision recognition (optional) | 54 mm view camera *2 | 3.0 x 3.0 mm to 33.5 x 33.5 mm | |

| 27 mm view camera *2 | 1.0 x 0.5 mm to 24.0 x 24.0 mm | ||

| Placement speed | Chip | (optimum) | 17'500 cph |

| (IPC9850) | 12'500 cph | ||

| IC | 4'100 cph*3 | ||

| Placement accuracy | Laser recognition | ±0.05 mm (±3σ) | |

| Vision recognition (optional) | ±0.04 mm | ||

| Number of component to be attached | max. 60 (8 mm tape feeder) | ||

| Power supply | 200 to 415 VAC, 3-phase | ||

| Apparent power | 1.8 kVA | ||

| Operating air pressure | 0.5 ±0.05 MPa | ||

| Air consumption | 345 l/min (optional: vacuum pump with 50 l/min) | ||

| Machine dimensions (W x D x H)*4 | 1,455 x 1,295 x 1,510 mm | ||

| Mass | approx. 1000 kg | ||

*2 Upward looking component centering camera is optional. Choose from either a 54 or 27mm field of view.

*3 Estimated value when using Vision centering system, Simultaneous pick up for components 10mm or smaller QFP or BGA by all nozzles.

*4 Dimensions of machine described are for conveyor height 950mm.

Options

| for Insertion Mounting | Component handling and feeders | Bowl Feeder (MBF) / Radial Feeder (MRF) / Table for radial components | |

| Conveyor | Handle arm (forMBF)*1 | ||

| for Surface Mounting | Recognition system | Vision centering system,*2 (54 mm view camera, 27 mm view camera) | |

| Safety device | Feeder floating detecting sensor (front) / Feeder floating detecting sensor (rear) | ||

| Others | Residual number-of-components control | ||

| Component handling and feeders | Tape feeder 8 to 72 mm / Bulk feeder / Stick feeder / Feeder stocker / Connector gig for tape | ||

| for Insertion Mounting and Surface Mounting | Conveyor | Conveyor extension guide / Conveyor height 900 mm | |

| Safety device | Ground-fault interrupter | ||

| Others | Caster / Vacuum pump / Main line filter / Quick connect coupling / | ||

| Three-color signal light (with buzzer) / DVD , CD-ROM drive (USB) / FD drive (USB) / ATC 6-6 | |||

| Software | EPU | ||

| Component handling and feeders | Tray Holder / Tape reel mounting base (for Tape Feeder,MRF) | ||

*2 Upward looking component centering camera is optional. Choose from either a 54 or 27 mm field of view.

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky