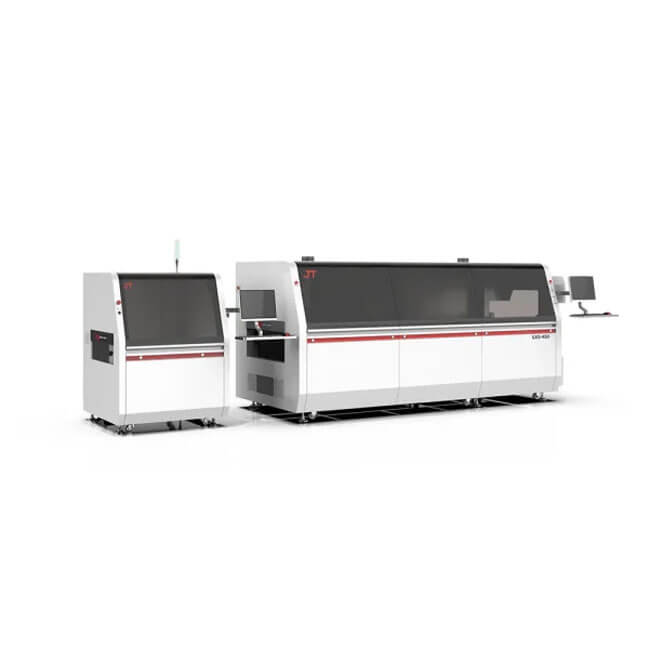

JT GXS-350-M Wave Soldering Machine

GXS Series of Wave Soldering Machine

● New solution of preheating:

The hot air preheating u- shaped heater, long service life, reduce maintenance downtime. Internal reinforcement insulation plus optional external protection device can effectively reduce the heat loss , energy saving up to 20% compare with traditional equipment. Low equipment surface temperature can optimize the working environment.

● External Spray Fluxer , safety, cost, space and maintenance problems resolved:

External Spray Fluxer combined the advantages of inner and independent spray, the spray and machine can be integrated control, no increase in cost; Spray fluxer away from preheating zone, and ensure safety and clean; Transportation of new type titanium alloy heavy duty claw, sectional guide rail design, stainless steel strip supported in guide rail, long life; The solder pot adopts special materials, Anti corrosion coating on surface; Adopt imported precision nozzle, atomization uniformity, high efficient.

● The large promotion of solder pot:

Nozzle quick released, reduce maintenance time, 2 hours to a few minutes; Grid type of mesh, reduce the mesh block by solder dross monthly maintenance extended to six months; Optional solder supply device, reduce the influence of wave height caused by the change of tin solder level;

Description

| Model No. | 350 Series |

| GXS-350-M | |

| Dimension(L×W×H)mm | 3885*1655*1710 |

| Spray Fluver Dimension (L*W*H)mm | 1300*1350*1595mm |

| Power Supply | AC 380V 3Φ5W 50/60Hz (Option :AC 220V3P 50/60Hz) |

| Initial/Operating Power | 80KW/8KW |

| Starting power | 37KW |

| Air Source | 0.5-0.8Mpa |

| Control System | PC+PLC |

| Flux Flow | 10〜100ml/min |

| Exhaust Tube Diameter | Φ 200 mm |

| Exhaust Mode. | Upward |

| Preheat Mode | IR / Hot Air |

| Preheat Zone Number | 3 zones/1800mm |

| Preheat Temp. Range | Room Temp.〜230℃ |

| Temp. Control Mode | PID+SSR |

| Solder Pot Type | Mechanical Pump |

| Pot Capacity | Approx. 480kg |

| Max. Soldering Temp. | MAX :300 ℃ |

| Wave Driving Power | 1/4 HP X2 |

| Wave Height Control | Inverter |

| Heat Up Time | Approx .150min (Setting:250℃) |

| PCB Conveying Speed | 300〜1800mm/min |

| The Width Of PCB | 50-350mm |

| Component Height | Top:120mm Bottom: 25mm |

| Transport Height | 750±20mm (Entrance) |

| Conveyor Angle | 4〜7° Adjustable |

| Speed Control Mode | Inverter |

| Cooling Method | Forced Air Cooling (Opiton:chiller) |

| N2 System | SMART-350-M-N |

| Nitrogen Consumption | 15m³/h Below 1000ppm |

| Pressure Nitrogen Source | 0.5〜0.8Mpa |

| Oxygen Nitrogen Source | ≤10PPM |

| Oxygen Analyzer | Option |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky