Hanwha HM520 Pick and Place Machine

Hanwha HM520 Modular Pick and Place Machine is the ideal mounter for high volume/high-performance electronics, such as mobile phones and automotive applications. With component sizes shrinking and PCBs becoming more densely populated, placement repeatability and accuracy are more critical. The Hanwha HM520 series is ideally suited to this style application. The HM520 HS Module can handle the smaller chip components at a very high speed using the rotary heads to achieve that. The FS module is a multi-function module, capable of placing larger components up to 55mm square including shield can devices. HM Series machines are fully traceable from component tracking, PCB tracking by barcode, and fully Intelligent system. All are managed and controlled by the T-Solution Factory management software.

Key Advantages of HM Series:

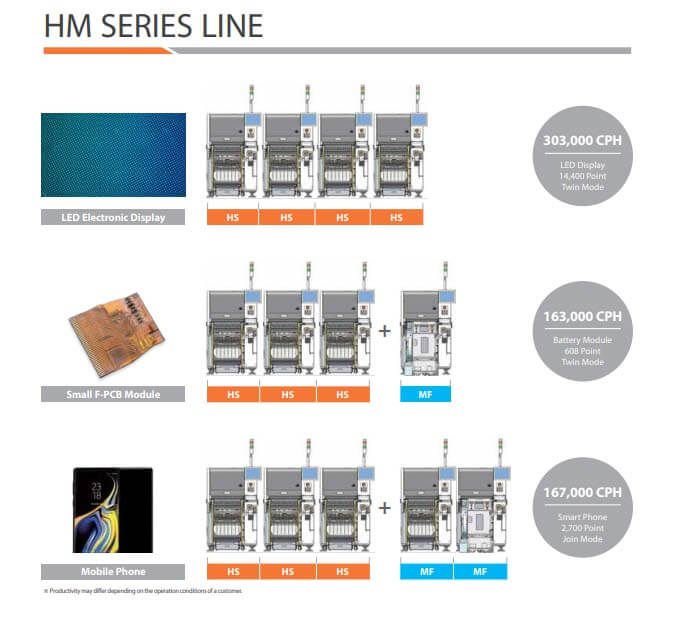

Reduction in Line Length with High Throughput

Very Low Cost of Ownership

Easy to use Software

Ideal for high-volume/High Mix production

Improved Axis and frame design over previous chip shooter models giving greater speed and higher precision

Improved component range and now capable of placing 0.2mm x 0.1mm components at high speed

Easy to use MMI and Off-Line Software with Touch Screen for operator convenience

Fully Modular System depending on target cph needed and feeder requirement

New Feeder Type for High-Speed Indexing and intelligent as standard

Hanwha HM520 modular Pick and Place Machine

Hanwha HM520 Chip Mounter

Patch speed: 80,000 CPH

size:890x2370x1930mm

weight:1605KG

Product description: Hanwha HM520 modular pick and place machine, it's Hanwha's first modular chip mounter, 890MM in length.

Patch speed: 80,000 CPH,Spindle head, Size:890x2370x1930mm,weight:1605KG

Hanwha HM520 modular Pick and Place Machine, it's Hanwha's first modular chip mounter, 890MM length.

890MM length ultra-small chip mounter

80,000CPH(Rotary Head)

60,000 CPH (Piano Head)

LED products: 72,000 CPH (Rotary)

Automatic detection of pick and placing problem.

Automatically replenishing suction/mounting position and height deviation

Preventing LED defects caused by turning

PCB: Max (L) 750x (W) 580mm (optional)

Equipment size:2370x1440x890mmEquipment weight:1605KG

The Hanwha HM520 modular Pick and Place Machine is a high-speed Modular Chip Mounter equipped with Rotary Head.

03015Chip ~ 14mm can be basically corresponding, and through the application of high-speed.

High-precision electric feeders, improve the actual productivity and placement quality.

Hanwha HM520 Chip Mounter parameters Number of shafts: 10 shafts * 2 cantilevers Mounting Speed: 80000CPH (Rotary Head Conditions)Mounting accuracy: 1mElectrically Driven High Speed and High Accuracy

High Productivity

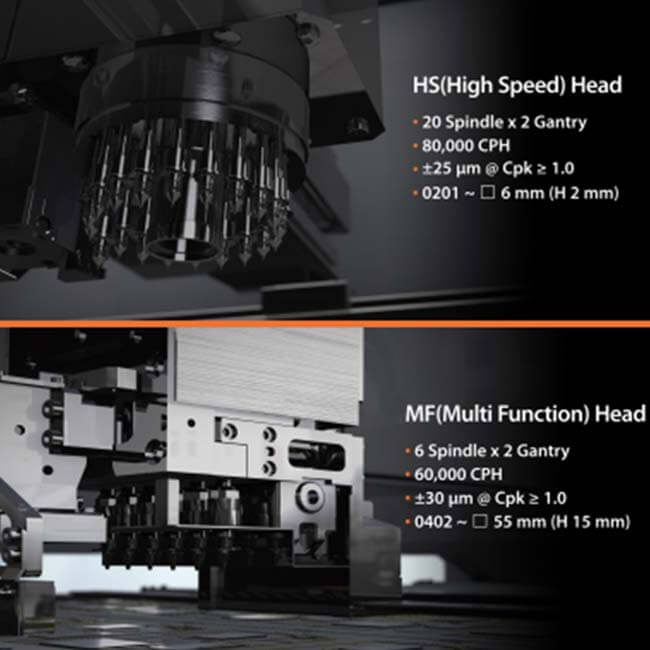

20 Spindle Head:

Design to small and light head So that can use Fix Camera to identify 20 Spindle one time.

Fix Camera High clear High Pixel:

Use a high clear(5M) camera, Can pick and place Mini LED chip, Mobile phone micro chip(0402,0603) in high speed.

HM Feeder(8mm):

New design 8mm HM feeder, successively shorted 24% pick and place time.

Optimized LED production:

By Adapting Rotary head, reached 74000CPH real production speed with a few HM feeders.

Enlarged Area Productivity:

Enlarged PCB production size(L750mm), Shrinked equipment length(W0.89M), Highly enlarged unit area's productivity.(40% more than Decan Series Pick and Place Machine).

Reduce Cycle time by sharing Badmark information:

Share bad mark information identified by first equipment with other equipment in the smt assembly line, Reduced cycle time by sharing these bad mark information.

High Reliability

Side View Camera, Prevent missing components:

Check nozzle status and components status during the production process, checking before placing the component on PCB and after place component on PCB to prevent component miss placing problem. And check the component height in real-time and automatically correct component position on PCB to prevent bad component placing.

Automatic correct picking and placing position:

Use the COR data from the Calibration result to correct pick and place position to prevent placing mistakes.

Height Sensor:

Can pick Emboss components without teaching by using Height Sensor, Automatic correct placing position tolerance caused by curved PCB.

LED components invert checking function:

Checking component invert or not by Vision Camera to prevent bad component placing on PCB.

| MACHINE TYPE | High Speed Machine | LED Machine | Multi Function Machin |

| THE NUMBER OF SPINDLES | 20 spindles x 2 Gantry | 20 spindles x 2 Gantry | 6 spindles x 2 Gantry |

| (Rotary Type) | (Rotary Type) | (Piano Type) | |

| PLACEMENT SPEED | 80,000 CPH (Optimum) | 80,000 CPH (Optimum) | 60,000 CPH (Optimum) |

| PLACEMENT | ±25 μm @ Cpk ≥ 1.0 (Chip) | ±25 μm @ Cpk ≥ 1.0 (Chip) | ±40 μm @ Cpk ≥ 1.0 (Chip) |

| ACCURACY | ±30 μm @ Cpk ≥ 1.0 (IC) | ||

| COMPONENT RANGE | 0201 ~ □ 6 mm (H2mm) | 0201 ~ □ 6 mm(H2mm) | 0201 ~ □ 6 mm (H15mm) |

| PCB SIZE (MM) | 510 x 580(Single Lane) | 510 x 580(Single Lane) | 510 x 580(Single Lane) |

| 510 x 310(Dual Lane) | 510 x 310(Dual Lane) | 510 x 310(Dual Lane) | |

| Max. 750 x 580,750 x 310 (Option) | Max. 750 x 580,750 x 310 (Option) | Max. 750 x 580,750 x 310 (Option) | |

| PCB THICKNESS (MM) | 0.3 ~ 4.2 | 1.0 ~ 4.2 | 0.3 ~ 4.2 |

| FEEDER CAPACITY | 80 ea (Docking Cart) | 8 ea (Fixed Base) | 80 ea (Docking Cart) |

| (8 MM STANDARD) | |||

| WEIGHT (KG) | Approx. 1,605 | Approx. 1,605 | Approx. 1,605 |

| EXTERNAL DIMENSION (MM) | L890 x D2,312 x H1,921 | L890 x D2,312 x H1,921 | L890 x D2,312 x H1,921 |

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky