Hanwha HM520 HS Pick and Place Machine

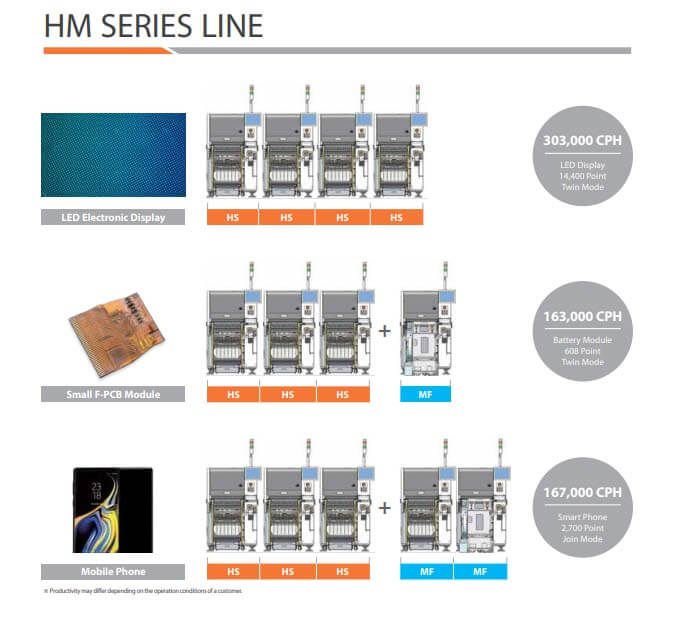

Hanwha HM520 Modular Pick and Place Machine is the ideal mounter for high volume/high-performance electronics, such as mobile phones and automotive applications. With component sizes shrinking and PCBs becoming more densely populated, placement repeatability and accuracy are more critical. The Hanwha HM520 series is ideally suited to this style application. The HM520 HS Module can handle the smaller chip components at a very high speed using the rotary heads to achieve that. The FS module is a multi-function module, capable of placing larger components up to 55mm square including shield can devices. HM Series machines are fully traceable from component tracking, PCB tracking by barcode, and fully Intelligent system. All are managed and controlled by the T-Solution.

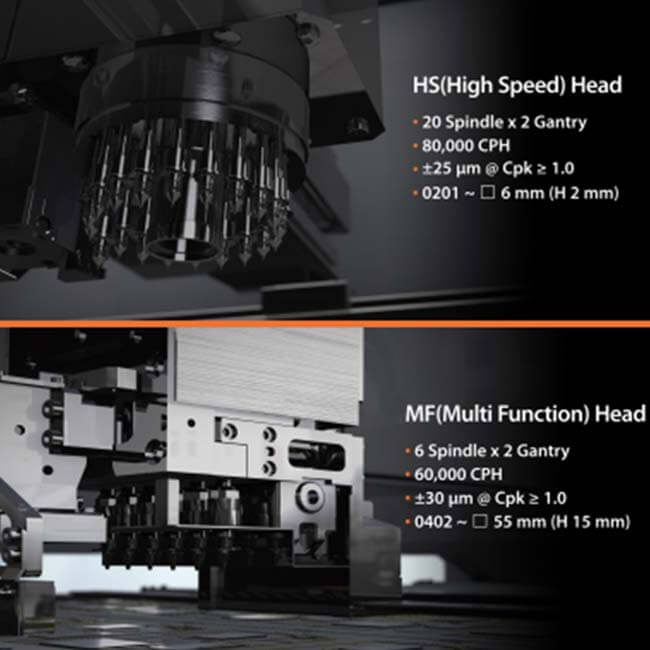

Number of Heads:Double Gantry 20 Heads (40 total)

Placement Speed:80,000 CPH (Vision Optimum)

Vision:Vision Stage Camera

Placement Accuracy:Chip: ±25µm Cpk ≥ 1.0

Dimensione:0201 - 6 mm

Max Altezza:2mm

PCB Dimension (mm)-Single:- 50 x 40 - 510 x 580mm (Standard)/- 50 x 40 - 750 x 580mm (Option)

PCB Dimension (mm)-Double:- 510 x 310mm (Standard)/- 750x330mm (Option)

Feeder Capacity (8mm standard):80ea (8mm Docking Cart)

Power:AC200/208/220/240/380/41SV±10% 3phase S0/60Hz

Weight:1,605kg

External Dimension (LxDxH mm):890x2,312x1,921

| MACHINE TYPE | High Speed Machine | LED Machine | Multi Function Machin |

| THE NUMBER OF SPINDLES | 20 spindles x 2 Gantry | 20 spindles x 2 Gantry | 6 spindles x 2 Gantry |

| (Rotary Type) | (Rotary Type) | (Piano Type) | |

| PLACEMENT SPEED | 80,000 CPH (Optimum) | 80,000 CPH (Optimum) | 60,000 CPH (Optimum) |

| PLACEMENT | ±25 μm @ Cpk ≥ 1.0 (Chip) | ±25 μm @ Cpk ≥ 1.0 (Chip) | ±40 μm @ Cpk ≥ 1.0 (Chip) |

| ACCURACY | ±30 μm @ Cpk ≥ 1.0 (IC) | ||

| COMPONENT RANGE | 0201 ~ □ 6 mm (H2mm) | 0201 ~ □ 6 mm(H2mm) | 0201 ~ □ 6 mm (H15mm) |

| PCB SIZE (MM) | 510 x 580(Single Lane) | 510 x 580(Single Lane) | 510 x 580(Single Lane) |

| 510 x 310(Dual Lane) | 510 x 310(Dual Lane) | 510 x 310(Dual Lane) | |

| Max. 750 x 580,750 x 310 (Option) | Max. 750 x 580,750 x 310 (Option) | Max. 750 x 580,750 x 310 (Option) | |

| PCB THICKNESS (MM) | 0.3 ~ 4.2 | 1.0 ~ 4.2 | 0.3 ~ 4.2 |

| FEEDER CAPACITY | 80 ea (Docking Cart) | 8 ea (Fixed Base) | 80 ea (Docking Cart) |

| (8 MM STANDARD) | |||

| WEIGHT (KG) | Approx. 1,605 | Approx. 1,605 | Approx. 1,605 |

| EXTERNAL DIMENSION (MM) | L890 x D2,312 x H1,921 | L890 x D2,312 x H1,921 | L890 x D2,312 x H1,921 |

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky