Hanwha HM510 Pick and Place Machine

High level of performance:

Flexible PCB Assembly System

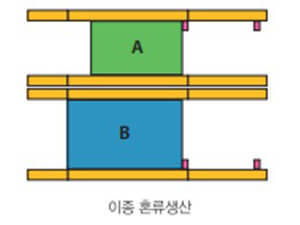

The possibility of using a single or double conveyor depending on the user’s working conditions, as well as mixed production of various models due to the use of two conveyors.

Single pipeline mode Dual-pipe mode

Multi mode

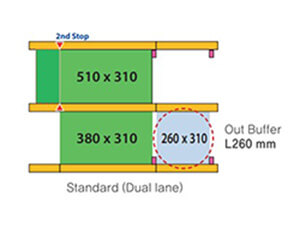

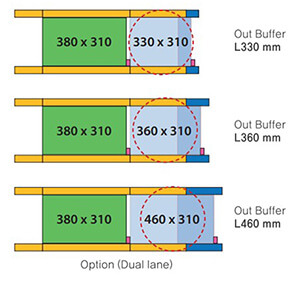

Output buffer

Increase actual productivity by optionally increasing the length of the output conveyor.

Solution for non-standard shaped components:

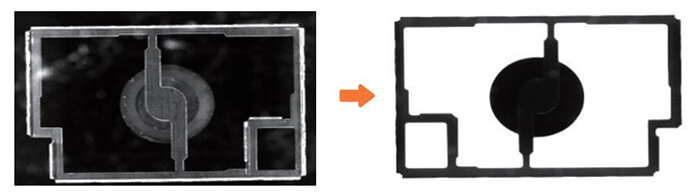

Bottom Light

Accurate detection of non-uniformly reflective and translucent components (variation of reflection).

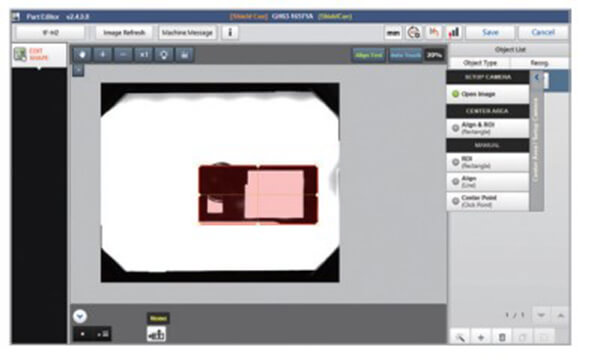

NPE function

New component registration system based on Drag & Drop technology, allowing you to register component information through automatic recognition with a simple mouse click. Recognition accuracy is improved by using the noise removal function on the component image.

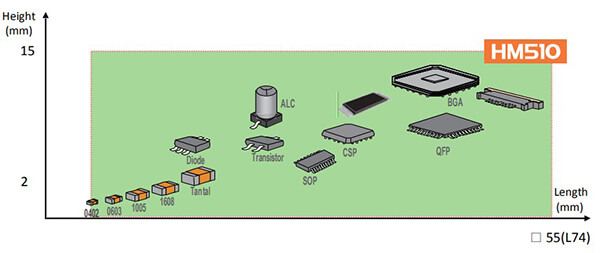

Versatility to solve any problems of modern installation technology

High speed, accuracy and the ability to mount a wide range of components.

High level of reliability:

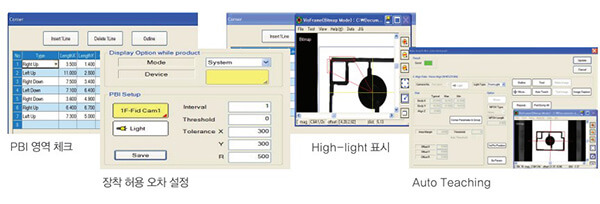

Control of poor-quality installation of components (PBI - post-installation inspection)

Checks the placement status of components in the Shield-Can system to prevent improper installation of components.

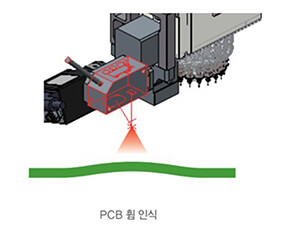

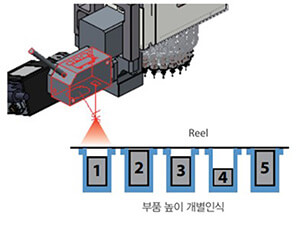

Height sensor

Captures the component using a height sensor and automatically corrects differences in installation height due to PCB warpage.

Easy to operate:

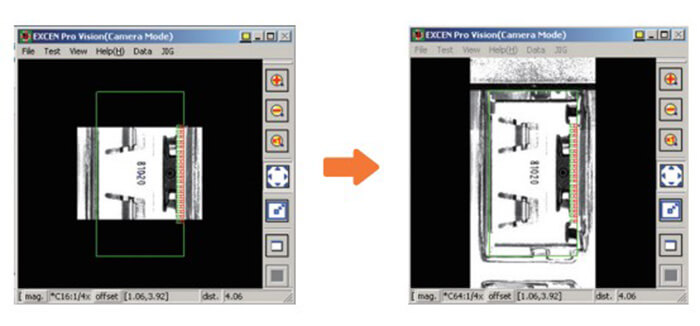

Panoramic View Function

Since large components are not displayed on the same screen, it is difficult to adjust their pick-up or placement position on the PCB. To eliminate such inconveniences, a panoramic viewing function has been added, allowing you to view large components in several stages.

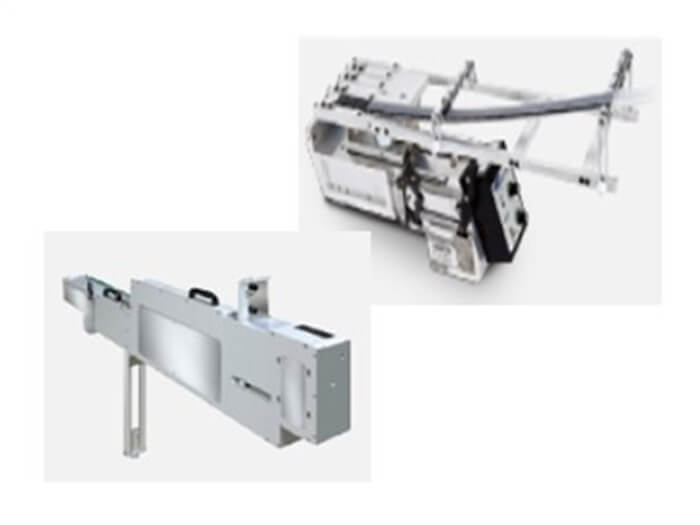

Trolleys for group change of feeders and automatic pallet change system

To the left of the automatic pallet changing system, you can additionally install a fluxing unit or 7 8 mm feeders. In addition, the automatic pallet changing system can be replaced very quickly with a trolley for group changing of feeders.

Tray feeder Docking trolley

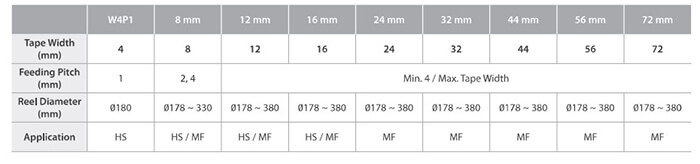

BELT FEEDERS

Tape width (mm) — Tape width (mm)

Feeding pitch (mm) - Feed pitch (mm)

Reel diameter (mm) — Reel diameter (mm)

TYPES OF FEEDERS

HM Feeder (new 8mm HM feeder reduces feed time by approximately 24% compared to existing feeders).

Feeder for pencil cases

Device for applying flux (Fluxer)

Distributes flux using a sliding method, providing high speed and high accuracy.

Pallet feeder

| Model | Hanwha HM510 Pick and Place Machine |

| Weight (KG) | 1600 |

| Showroom Location | United States, Russia |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product |

| Warranty of core components | 1 Year |

| Core Components | Hanwha HM510 |

| Place of Origin | South Korea |

| Brand Name | samsung hanwha |

| Warranty | 1 Year |

| Product name | SAMSUNG Hanwha HM510 Pick And Place Machine |

| Application | for smt line |

| Type | Hanwha smt pick and place machine |

| Quality | hight quality |

| High Speed | 60,000 CPH |

| Placement Accuracy | ±40 μm @ Cpk ≥ 1.0 (Chip) / ±30 μm @ Cpk ≥ 1.0 (IC) |

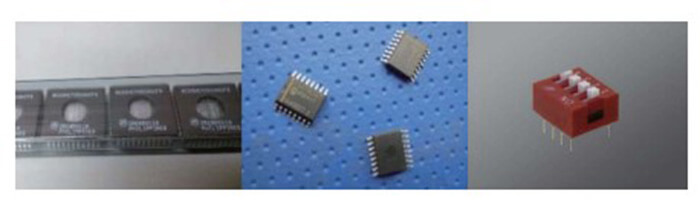

| Component Range | 0402 ~ □ 55 mm |

| Number of Spindles | 6 spindles x 2 Gantry (Piano Type) |

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky