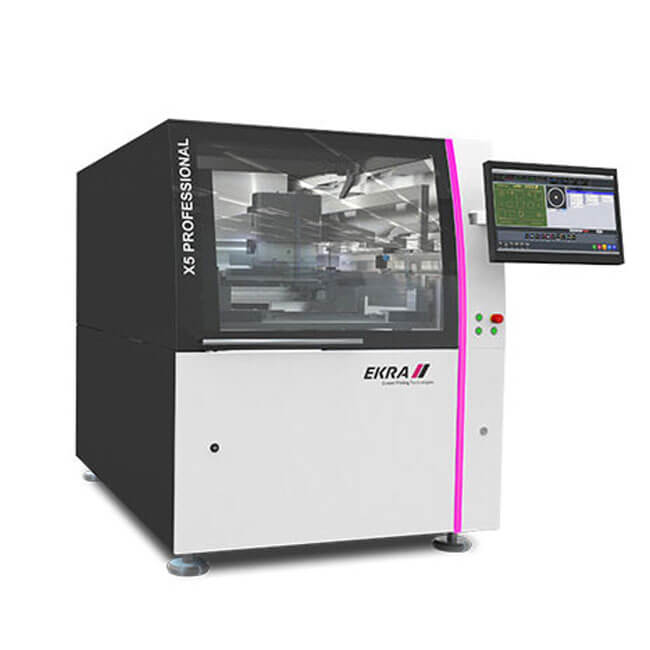

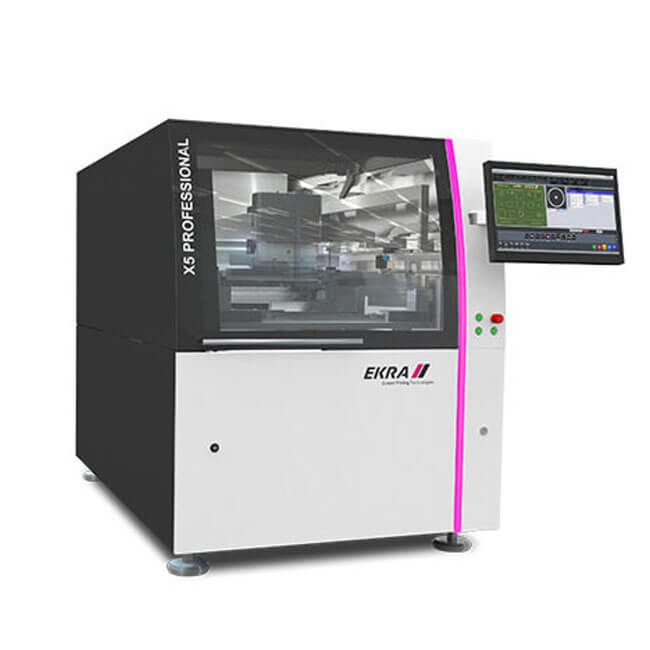

EKRA X5 professional Solder paste printer

Maximum output at highest precision

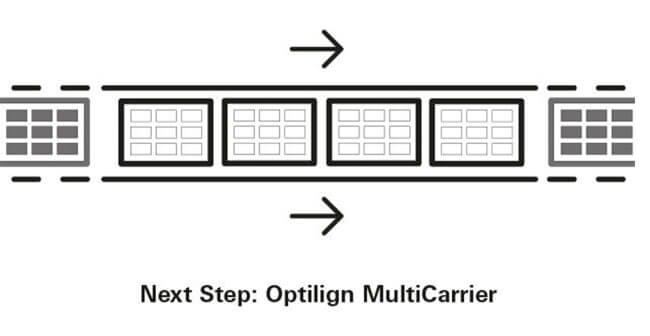

The X5 Professional Optilign MultiCarrier impresses with productivity at the highest level

The X5 Professional Optilign MultiCarrier extends EKRA's proven Optilign option. Now up to six product carriers or PCBs can be printed simultaneously. Productivity on the line increases with maximum print repeatability. Stretch problems are effectively eliminated thanks to the ingenious process. The stencil and squeegee blades have a reduced wear and tear, as more output is achieved in one printing process than with a conventional method. In addition, the consumption of cleaning paper, recalculated for the individual circuit, is reduced.

The Optilign MultiCarrier option is available for the X5 Professional printing system and can be easily integrated into an existing line concept. Many circuit board sizes and even individual circuit boards can be processed. Thus, the X5 Professional with Optilign MultiCarrier is ready for highly complex and standard applications.

High performance

Cycle time 8 sec + print

Fast product changeover < 2 min

Easy to upgrade for future needs

User-friendly software with touchscreen

Repeatability ± 12,5 μm @ 6 Sigma

Up to 610 x 510 mm boards

More Throughput

Simultaneous Processing of four substrates or carrier

Compensating Stretch

Single substrates instead of multi circuit boards

Highest Precision in Ultra-Fine-Pitch

separate adjustment of the single printing areas

The process in detail

Individually aligning, simultaneously printing - this is the principle behind Optilign. This allows multi-row carriers with the smallest of circuit boards to be processed quickly and precisely. The printed circuit boards are lifted out of the carriers individually by vacuum and then aligned on the X, Y and theta axes. Each individual substrate is positioned exactly to the stencil, completely independent of PCB tolerances.

With Optilign MultiCarrier, this is now possible for several product carriers simultaneously. The printing machine collects up to six carriers, which are transported together into the process area. Each substrate is then individually aligned and then all carriers are printed simultaneously in one step. Afterwards the carriers are transported together into the outfeed. The outfeed passes the carriers on again individually to the next production station. Instead of using large and therefore expensive individual carriers, Optilign MultiCarrier uses several small product carriers. This increases the cost efficiency of the entire production process. Instead of product carriers, Optilign MultiCarrier can also directly process up to six PCBs with a total length of up to 510mm.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky