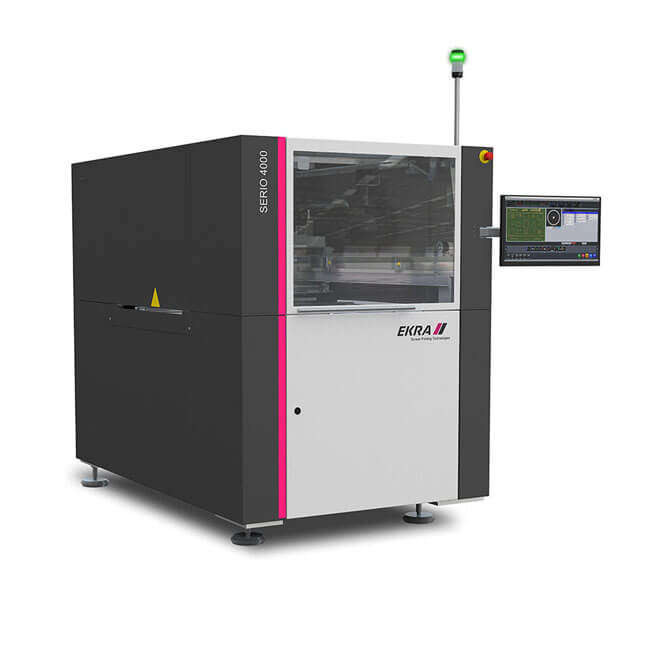

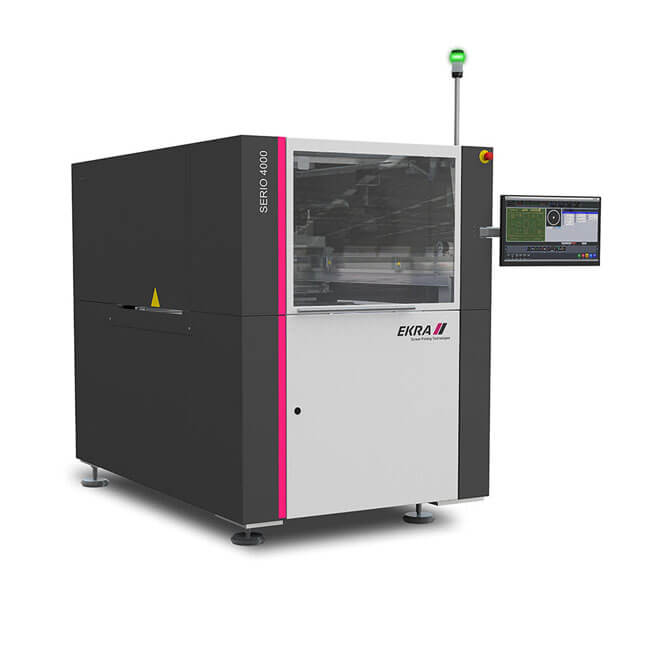

EKRA SERIO 4000 Solder paste printer

The S4 is the further development of our well-known SERIO series. The outstanding feature is the dynamic scalability. Equip the system with the options and features you need individually. Your production is developing towards the future and our S4 grows with it: You can expand any initial configuration at any time. Whether it's a standard application or a demanding application, with the S4 we offer you maximum flexibility and scalability.

Minimal footprint 100 x 127 cm

Possibility to place 2 printers “back to back”

Easy to use software with touchscreen

Alignment repeatibility ± 12,5 μm @ 6 Sigma

Program changeover < 2 min

Closed loop with SPI (option)

The ultimate Standard

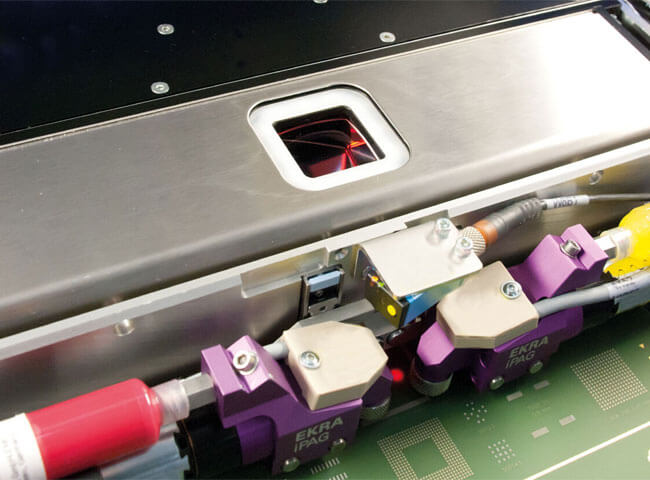

EVA Camera System

The patented EVA™ vision system is equipped with two high-resolution CCD cameras mounted into one camera module. The camera module measures the fiducial marks, while the camera moves between the stencil and the substrate. Then the board is aligned with the stencil and – using its two, independent, programmable light sources EVA™ can even recognize low contrast and uneven marks.

iQUESS Squeegee exchange system

The iQUESS squeegee exchange system enables squeegee changes within 20 seconds. The “Poka – Yoke” click and fit system is the standard with all SERIO 4000 systems.

iROCS Light Stencil Cleaning

The stencil cleaning iROCS light is an oscillating cleaning system. It works optionally dry, wet, as well as with or without vacuum, by means of low-lint cleaning cloth, which is transported consumption-optimized.

Scalable to Infinity

Over 160 extensions make all configurations possible

iSET

The RFID setup control is started by pressing a button. The setup sequence is is no longer relevant, only components that have been set up in the printer are detected.

MCU

The modular camera unit (MCU) recognizes modules and adjusts the control fully automatically. Module-specific parameters and settings are loaded in parallel

Fill level measurement of cleaning fluid

The fill level monitoring system ensures even and consumption-optimized moistening of the cloth surface.

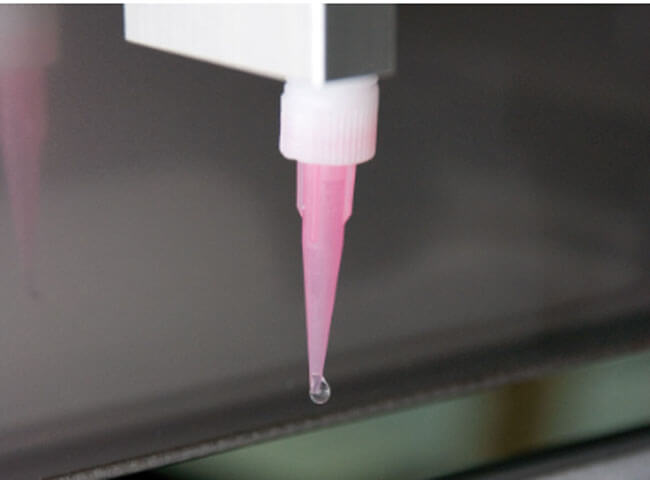

Paste Height Detection

The paste height detection monitors the paste quantity. If the paste falls below the set level, an automatic dispensing process is initiated.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky