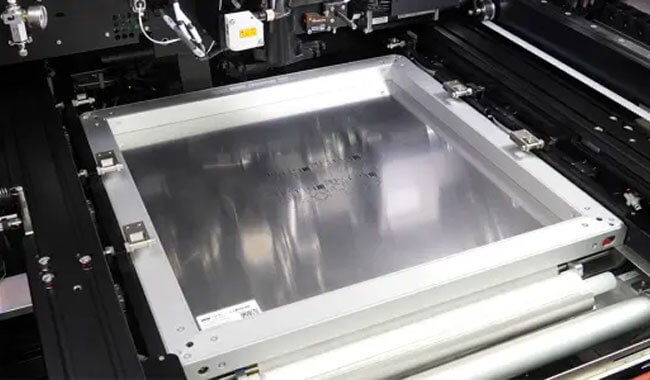

DEK TQ Solder paste printer

Maximum quality and performance paired with high flexibility.

The DEK TQ is superfast (core cycle time: only 5 to 6.5 seconds), highly precise (±17.0 microns @ 2 cmk), and a real space-saver. With two model versions, the platform now also features outstanding flexibility: the DEK TQ for boards measuring up to 400 by 400 millimeters, and the DEK TQ L for boards measuring up to 600 by 510 millimeters.

New three-stage conveyors, the unique ASMPT NuMotion controller with fiber-optic cabling and up to 50 percent faster cleaning processes guarantee high-speed operation. New drives, off-belt printing and innovative clamping systems deliver unprecedented accuracy and an exceptionally stable printing process. With the Dual Access Cover for paste cartridge changeover without stopping the printer, automatic Smart Pin Support and a series of more smart features, the printers run on average for more than eight hours without a single user assist. With its many interface standards, the DEK TQ printer platform fits seamlessly into the intelligent factory while its growing number of options automates setup changeovers and minimizes operator assists.

Highlights

Maximum printing quality: New clamping process for off-belt printing, an innovative printhead and drive, and full-area pneumatic stencil clamping

Maximum precision: Wet-print accuracy of up to ±17.0 microns @ 2 cpk Paste printing for 0201m components

Maximum throughput: Core cycle time of 5 seconds (DEK TQ) and 6.5 seconds (DEK TQ L)

Fast 3-stage transport: Linear drives, innovative clamping systems, off-belt printing, ASMPT NuMotion controller

Up to 8 hours without assists: Understencil cleaning system with 22-meter fabric roll and 7-liter cleaning fluid supply, automatic paste management, and automatic Smart Pin Support

Efficient programming: New instinctive software and offline programming with WORKS software

Best floorspace performance: Footprint of only 1.3 square meters (DEK TQ) and 1.95 square meters (DEK TQ L)

Back-to-back: The perfect solution for dual-conveyor lines

Options

Automatic Smart Pin Support: DEK TQ 30-pin magazine or DEK TQ L up to 60-pin magazine (4-mm and 12-mm pins)

DEK Automatic Paste Dispenser: Automatic paste application with paste height control

Dual Access Cover: Easy paste cartridge/pot exchange without printer and line stop

DEK All Purpose Clamping: Flexible and totally software-controlled vertical and lateral clamping

High Flow Vacuum: Special large-area vacuum system incl. flexible tooling box – ideal for carriers

Closed-loop link to SPI systems: Expanded solder paste control with ProDEK DEK TQ printer platform

Specifications

Maximum print area:400 mm (X) × 400 mm (Y) (1-stage conveyor)

Machine dimensions:1000 x 1300 x 1600 mm (L x W x H)

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky