Automatick Ultrasonic Stencil Cleaner QT-1200

Features:

▶All stainless steel body: beautiful, wear resistance, corrosion resistance, acid, alkaline and other cleaning fluid. Meet environmental protection requirements and standards.

▶Full pneumatic operation, no electricity, no fire and other safety hazards, has passed the European Union safety regulations certification.

▶Specially used for cleaning printing ink, glue, paddle material, etc.

▶Cleaning + rinsing process to ensure cleanliness, liquid pressure can be shown by the panel pressure gauge.

▶The cleaning surface is large, suitable for 47 *47 net plate placement.

▶Cleaning pressure can be adjusted independently, suitable for any material screen.

▶Unique S-type exhaust device design, lower liquid consumption.

▶Equipment adopts precision six 100um- 10um filtration system, solvent circulation use.

▶Humanized design: one-button operation and automatic adding and draining function, the operation is very simple.

▶System integration of global high-quality devices: to ensure good quality, stable performance, long service life.

▶Configuration of an authoritarian professional air gun, increase humanized design manual drying and other functions.

▶Equipped with 2 80L solution cleaning tank, solution cleaning tank with filter ink removable filter screen, easy maintenance.

Product Details

Automatick Ultrasonic Stencil Cleaner QT-1200

What is stencil cleaning machine in the SMT process?

A kind of machine equipment for cleaning stencil in SMT work, mainly used for cleaning residues such as solder paste, red glue and silica gel on the stencil after printing

Application fields:

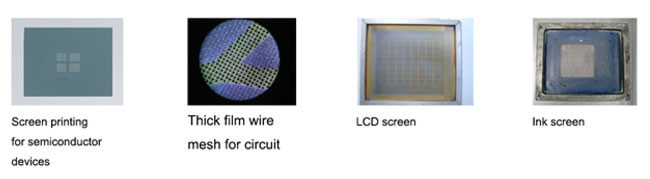

●Suitable for cleaning various screens such as wire mesh, glue mesh, microporous mesh and wafer trays

Cleaning method: 360° rotary cleaning fluid injection and high pressure air injection (cleaning → drying)

Technical parameters

Dimensions: 1600mm(L) ×1350mm(W) × 2200mm(H)

Cleaning method: 360° rotary cleaning fluid injection and high pressure air injection (cleaning → drying)

Max Applicable screen size: 1200mm(L) ×1200mm(W) × 40mm(H) ,special size needs to be customized

Liquid storage tank capacity: 80 liters *2PCS

Liquid is added for optimum usage:65L * 2 PCS

Filtration mode :(circular filtering)

Cleaning area filtration system eight precision filtration:

Primary filter: 1mm (filter particles, tape, etc.)

Two, three, four, five, six filters: 200 mesh (ink deep material)

7-stage filter: 10μm (filter element: ink, silver paste)

8 stage filter: 10μm (filter element: ink, glue, silver paste)

Exhaust outlet size: Φ75(D)×30mm(H)

Gross weight: 400 KG

Compressed air required pressure: 4.5kg /cm³ - 7Kg

Air consumption: 800-1000L/Min

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky