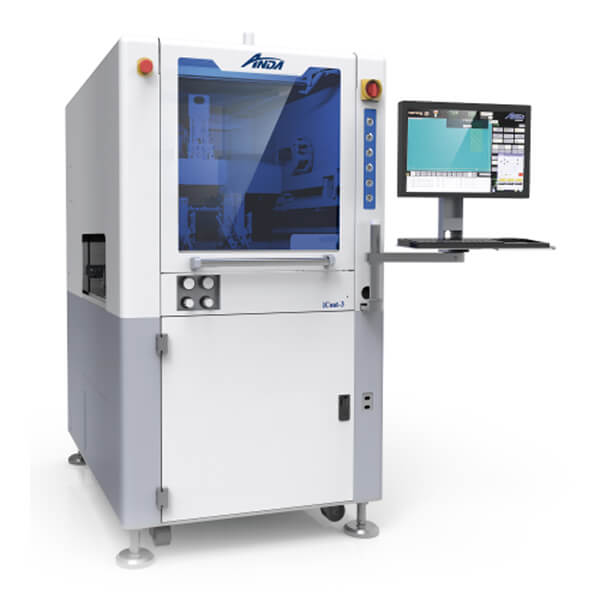

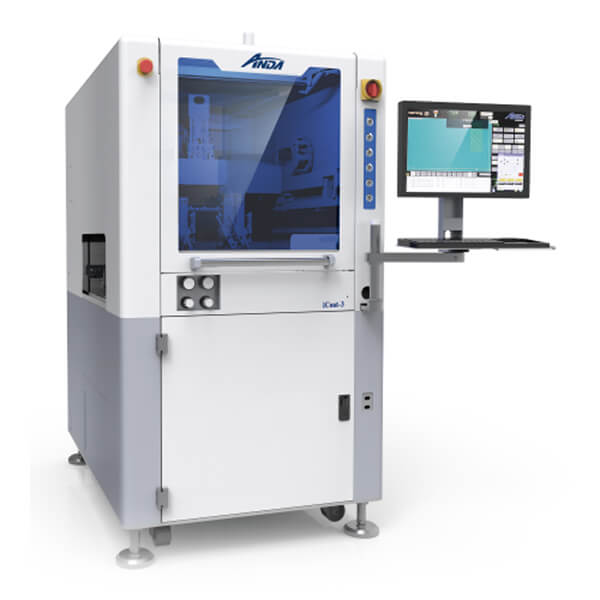

Anda iCoat-3 Conformal Coating Machines

Selective Conformal Coating Machine

ANDA’s iCoat-3 is a high-speed precision selective conformal coating machine that’s designed to strike a balance between cost and performance. Perfect for automating high volume/throughput or high mix low volume (HMLV) coating processes which don’t require valve rotation and 35° tilt (see iCoat-5 Series). Suitable for panelized or palletized printed circuit board assemblies (PCBAs) and large area coating applications.

- Running accuracy of ± 0.02 mm (20 µm) (± 0.0007ʺ)

- Three axes of movement (X,Y,Z)

- Supports up to four selective conformal coating valves in a variety of different nozzle arrangements including dual or quad valve configurations

Features

Standard Features

Running accuracy ± 0.02 mm (20 µm)

Gantry axes: X,Y,Z

Gantry: servo motors, ball screw drive

Steel structure smooth motion platform

Stainless steel interior

Hatch door with observation window

Adjustable height pivoting computer arm

Fluorescent inspection lighting (UV black light)

Auto dipping and purging waste collection

Programmable valve cleaning

Board presence sensors

Board clamping during coating

Unlimited program storage

USB communication ports

Light Tower Beacon

Optional Features

- Valve and / or fluid heating

- Dispense needle calibration sensor

- Inline material metering

- Laser film fan spray width control monitoring

- Material changeover (manual)

- Material level detection (low fluid level scale)

- Material tank AMSE certified: 1 / 3 / 5 / 10 gal

- Barcode program selection, 1D or 2D

- CCD vision programming camera w/ auto coating UV light spot inspection

- Fiducial find camera

- Non-contact laser height sensor

- Heavy duty conveyor 10 kg (22 lbs) max weight

- Dual lane conveyor

Multi-stage or multi-zone conveyor

Pre-queue board station

Return conveyor (underneath)

iCoat-3 Specifications

|

Motion System |

|

|

Gantry |

Servo motors, ball screw drive |

|

Gantry Axes |

X,Y,Z |

|

X-Travel |

450 mm (Standard), 580 mm (Optional) |

|

Y-Travel |

450 mm (Standard), 580 mm (Optional) |

|

Z-Travel |

100 mm |

|

XY Maximum Speed |

800 mm/sec |

|

XY Acceleration |

0.8 g with smooth control |

|

XYZ Repeatability |

± 0.02 mm (20 µm) (± 0.0007") |

|

Board Handling |

|

|

Standard Work Area |

X 450 × Y 450 × Z 100 mm |

|

(X 17.71" × Y 17.71" × Z 3.93") |

|

|

Large Work Area (Optional) |

X 580 × Y 580 × Z 100 mm |

|

(X 22.83" × Y 22.83" × Z 3.93") |

|

|

Maximum Components Height |

± 90 mm (± 3.54") from PCB |

|

PCB Edge Clearance |

≥ 5 mm (≥ 0.19") |

|

Minimum Conveyor Width |

50 mm (1.95") |

|

Max Standard Conveyor Width |

450 mm (18.11") |

|

Max Large Conveyor Width (Optional) |

580 mm (22.83") |

|

Process Flow (bidirectional) |

L to R (Standard), R to L (Optional) |

|

Chain Conveyor Weight Limit |

4 kg (9 lbs) [Standard], 10 kg (22 lbs) [Optional] |

|

Conveyor Motor Power |

DC 24 V 69 W × 2 |

|

Conveyor Speed (XY) |

0.5 – 5 m/min (1.6 – 16.4 ft/min) |

|

Conveyor Height |

900 ± 20 mm |

|

(35.43" ± 0.79") |

|

|

Conveyor Width Adjustment |

Automatic (motorized) |

|

Operation Configuration |

|

|

Valve Configuration (Standard) |

Dual valves in a row (fixed width) |

|

Valve Configurations (Optional) |

Quad valves; dual row (adjustable width) |

|

Dispense Valve Widths |

0.2 – 2 mm (0.0078" – 0.078") |

|

Spray Valve Widths |

1.6 – 30 mm (0.06" – 1.2") |

|

Maximum Speed |

800 mm/s |

|

Repeatability |

± 0.02 mm (20 µm) (± 0.0007") |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky