Hanwha Decan L2 Pick and Place Machine

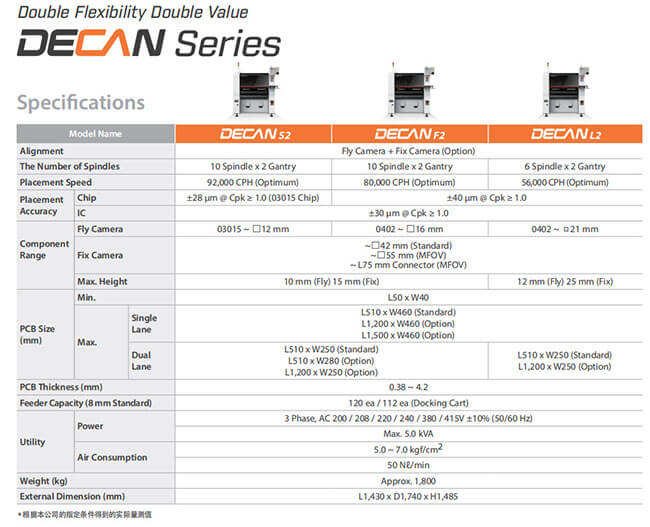

▶ Speed : 56,000 CPH (Optimum)

▶ Structure : 2 Gantry x 6 Spindles/Head

▶ Accuracy : ±40μm Cpk≥1.0 (0402 Chip)

±30μm Cpk≥1.0 (IC)

▶ Parts Size : 0402~□55mm, L75 (H25mm)

▶ PCB Size : L510xW460mm (Standard)

L1,200xW460mm (Option)

▶ Wide Part Handling Capability

▶ Various PCB Transfer Systems

▶ Verified Production History Management Solution

High Speed Placement

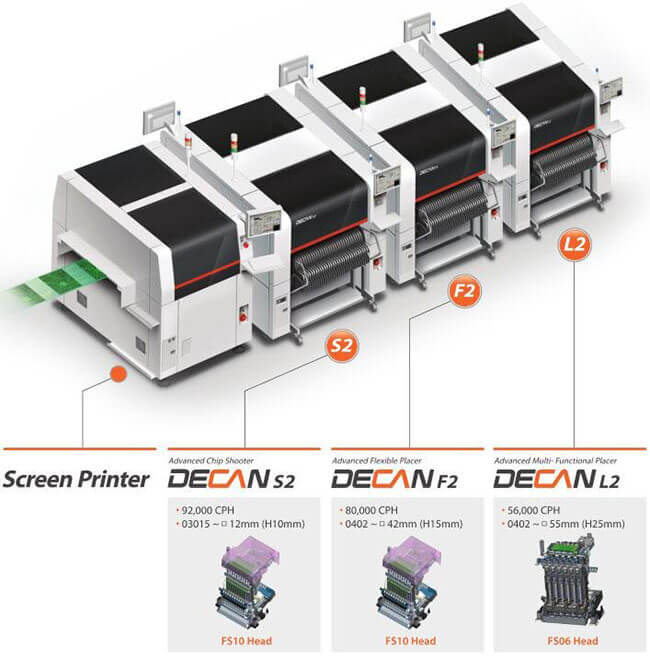

■ Optimal line configuration from chips to uniquely-shaped components according to options setup

Equipment capable of responding to large-scale PCBs, which can be remodeled on site

■ Standard equipment can be remodeled on site to equipment capable of large-scale PCB handling

– Responsive to a maximum 1,200 x 460mm PCB

Responsive to uniquely-shaped components (including tray components)

■ Responsive to a maximum 52mm(H25mm) IC when the stage vision option is applied

■ LED & LED lens placement with LED flipped & lens protrusions cognition

EASY OPERATION

Strengthened equipment software operation convenience

■ Convenient production and editing of work programs with built-in equipment optimization software

■ Provision of a range of work data and information on a large-scale LCD screen

High-precision, convenient electric feeder

■ Calibration and maintenance-free electric feeder

■ Improved work convenience with a single reel bank mounted feeder

■ Improved productivity through the provision of automatic parts pick-up position alignment between feeders

Reduced work load through parts connection automation (smart feeder)

■ Automatic loading and splicing capabilities implemented as an industry first

– Significantly reduction in work time through feeder preparation and parts connection operation automation which were previously carried out manually

■ Zero consumables costs for parts connection attained

■ Optimal line configuration from chips to uniquely-shaped components according to options setup

Equipment capable of responding to large-scale PCBs, which can be remodeled on site

■ Standard equipment can be remodeled on site to equipment capable of large-scale PCB handling

– Responsive to a maximum 1,200 x 460mm PCB

Responsive to uniquely-shaped components (including tray components)

■ Responsive to a maximum 52mm(H25mm) IC when the stage vision option is applied

■ LED & LED lens placement with LED flipped & lens protrusions cognition

EASY OPERATION

Strengthened equipment software operation convenience

■ Convenient production and editing of work programs with built-in equipment optimization software

■ Provision of a range of work data and information on a large-scale LCD screen

High-precision, convenient electric feeder

■ Calibration and maintenance-free electric feeder

■ Improved work convenience with a single reel bank mounted feeder

■ Improved productivity through the provision of automatic parts pick-up position alignment between feeders

Reduced work load through parts connection automation (smart feeder)

■ Automatic loading and splicing capabilities implemented as an industry first

– Significantly reduction in work time through feeder preparation and parts connection operation automation which were previously carried out manually

■ Zero consumables costs for parts connection attained

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky