Nordson AXI X# Series AXI SMT X-ray Inspection Machine

Overview

The X#-platform series is an inline automated X-ray system which covers a wide range of AXI applications. It is a flexible platform with very versatile fields of use depending on the application requirements. The inspectable applications range from component level inspection for wire bonds, large SMT boards, high-power electronic modules up to fully assembled modules.

Four In One - Advanced Technology

X-ray System Features

Flexible AXI system for inline and island of automation configurations

Microfocus X-ray tube (sealed tube / maintenance free)

Multiple programmable motion system with servo drives

Digital CMOS flatpanel detector

Automatic grey-level and geometrical calibration

Barcode scanner for serial number and product type selection

Full product traceability via customized MES-Interface

Highlights

Flexible setup for inline pass through or same-side in/out configuration

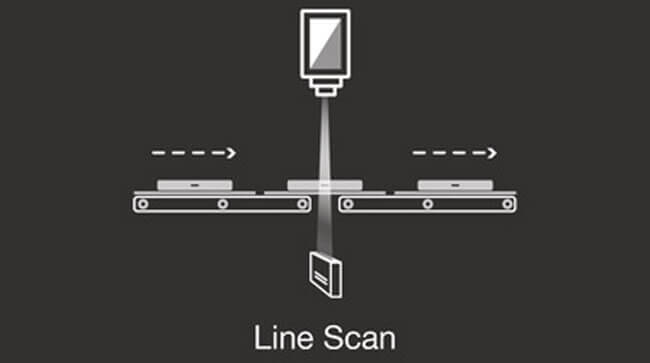

Combination with line scan camera for high throughput

Auto BCR scanning station (x-y gantry)

Low-dose radiation filter

Available Configurations

Depending on the type of product & inspection task

X2# Transmission (2D) + SFT™

X2.5# Transmission (2D) + SFT™ + Off-Axis (2.5D)

X3# Transmission (2D) + SFT™ + Off-Axis (2.5D) + 3D SART

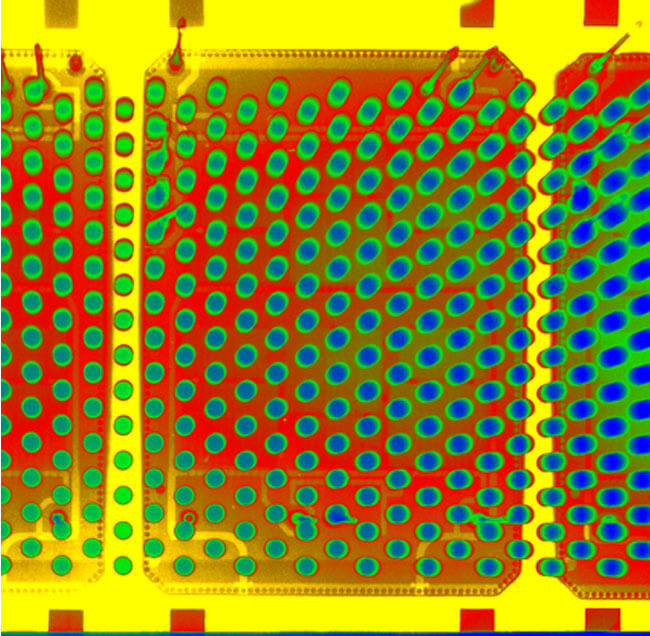

Applications

Inspection Technologies

The modular AXI system concept provides the unique capability to use several inspection technologies in one system. Depending on the specific application request the optimum inspection technique can be selected and/or combined.

2D Transmission

Transmission is two-dimensional image capturing with a fixed detector position

SFT Slice Filter Technique

High-speed technique using first side image to filter out from double-side image

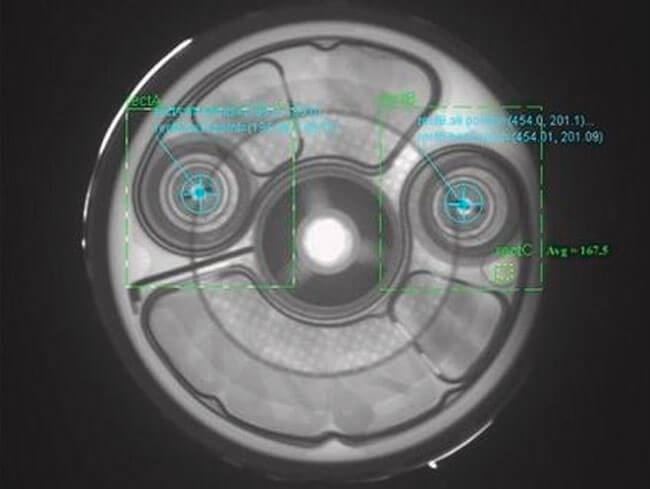

2.5D-Oblique View

AXI on programmable angle-shots up to 40 dgr (used for high performance BGA and PTH inspection)

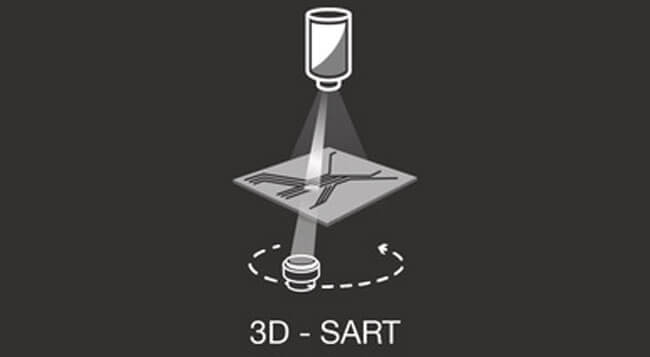

3D-SART

3D-Tomosynthesis to generate multiple horizontal slices used for high-dense double-sided and multi-chip-modules (MCM,LGA,…)

Line Scan

Fastest inspection technique using continuous scan via Line-Scan Detector to generate a large area X-ray image

Specifications at a Glance

| System | |

| Footprint | 1755 mm (H) x 3100 mm (W) x 1760 mm (D) |

| System Weight | 2,800 kg |

| Power Consumption | max.6 kW |

| Line Voltage | 400 VAC, 50/60 Hz 3 phase, 16 A/ |

| 208 VAC, 50/60 Hz 3 phase, 25 A/ | |

| Air Supply | 5-7 Bar, < 21/min, filtered (30μ), dry, oil free |

| Operation Temperature | 15°- 28 ° C optimal 20°-25°C |

| Adjustable conveyor height (SMEMA) | 890 - 980 mm |

| Inspection speed | |

| Transmission (X2#, X2.5#, X3#) | up to 3-4 views /s |

| Off-Axis (X2.5#, X3#) | up to 2-3 views /s |

| 3D Planar CT (X3#) | up to 3 s / FoV |

| Options | |

| Barcodereader | |

| Low-dose radiation filter | |

| Auto BCR scanning station (x-y gantry) | |

Jacky

Jacky Jacky

Jacky