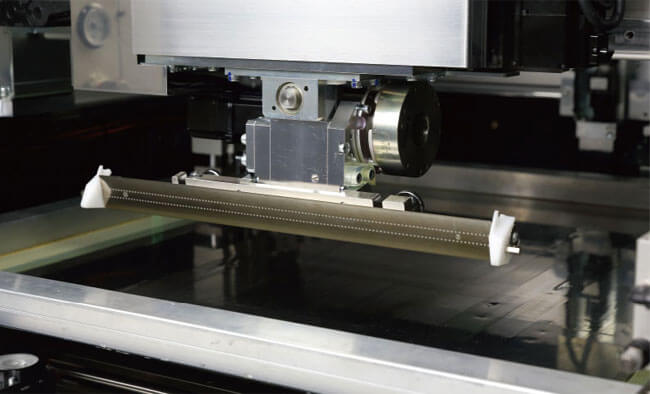

YAMAHA YCP10 Solder paste printer

Printing quality similar to flagship models, compatible with large PCBs and a wide variety of stencil frames

Built-in features from high-end machine models deliver high print accuracy and quality!

Multiple functions and extreme versatility all wrapped into 1 compact unit!

Support for Yamaha SMT production line network, delivers highly efficient production.

Built-in Features from High-end Machine Models Deliver High Print Accuracy and Quality!

YAMAHA’s original 3S head[3S:Swing Single Squeegee]

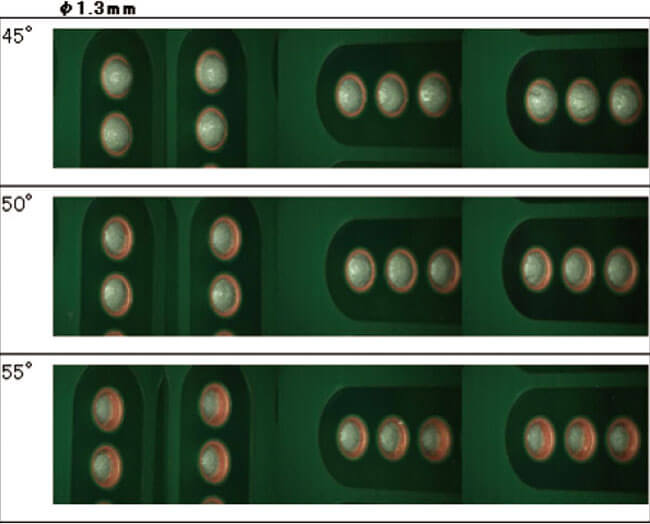

Program change squeegee attack angle (1 degree units between 45 to 65°) and speed to an ideal setting to provide optimal printing conditions that match the solder being used.

3S head: attack angle and volume

Also solder prints the thru-holes (view from rear side)

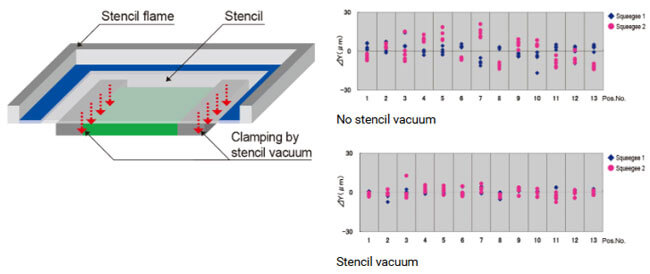

Stencil vacuum

A stencil vacuum mechanism delivers consistent high accuracy printing with no effects from stencil droop. Also drastically cuts the setup time since no offset entry is needed during back and forth printing movement.

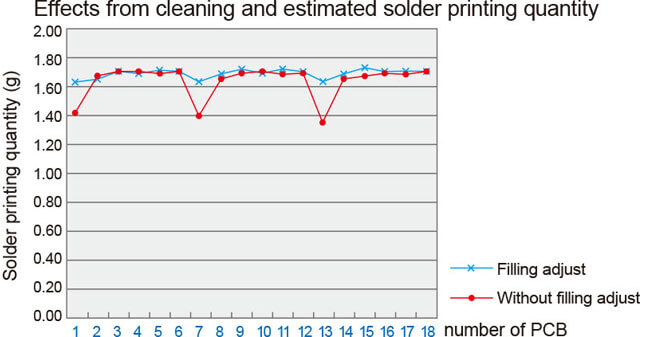

Filling adjust

Handy function corrects solder fill amount for the PCBs which have just finished cleanings and in this way cuts down on solder print irregularities.

Multiple Functions and Extreme Versatility All Wrapped into 1compact Unit!

Ideal for large-size boards and extra-wide stencils!

Though housed in a compact body, it handles large PCBs of L510×W460mm as well as a variety of stencils sizes to boost line productivity to the max!

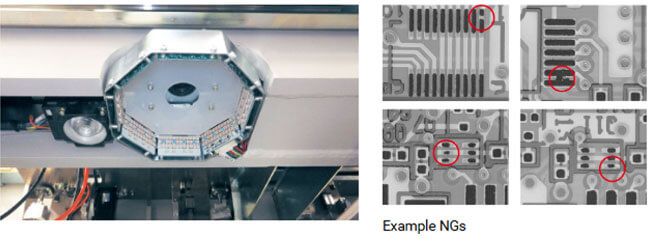

Printing inspection function(option)

Make full-on print inspections with a dedicated inspection camera offering a wide field of view and excellent resolution.

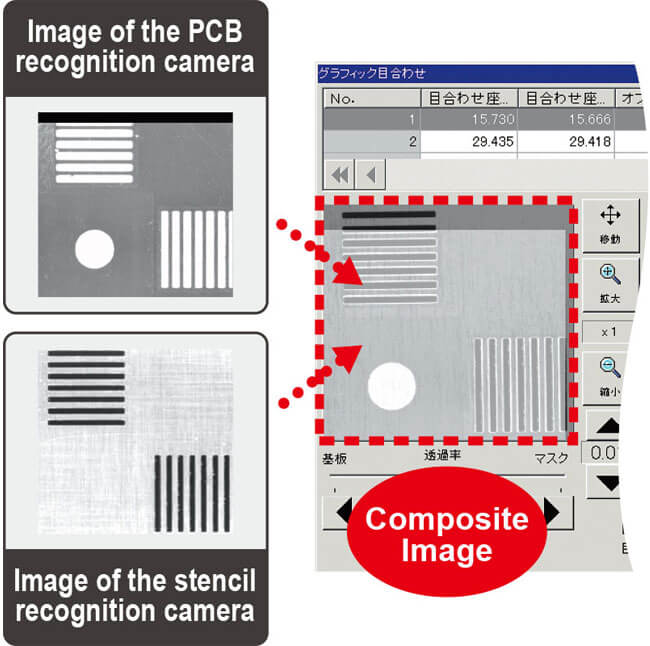

Graphic layer base alignment function

Advanced feature, superimposes 2 images in layers on the monitor, so position alignment can be checked at a glance. Now even a beginner can instantly make fine parameter adjustments for print position alignment.

Auto cleaning system

This system ensures cleaning that matches work conditions after making settings such as cleaning type, speed and suction.

Cleaner fluid bottle

Cleaner fluid is easily replaceable during production from a large capacity bottle mounted on front side of machine. The fluid remaining in the bottle can be easily checked at a glance.

Support for YAMAHA SMT Production Line Network, Delivers Highly Efficient Production.

IT option(Option)

ID monitoring of solder, stencil, and squeegees via barcodes prevents entry setting errors during setups and changeovers by matching PCB data with actual work task. This also lets the operator check solder expiration dates (humidity, oxidation, Guaranteed Time Limit).

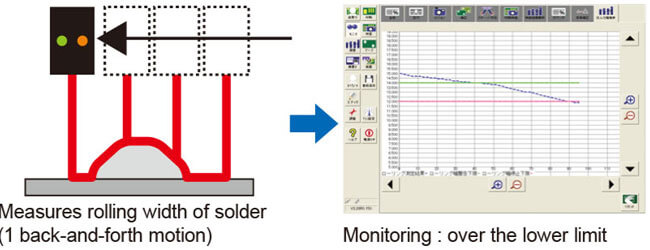

Solder remaining quantity detection function(Option)

Function periodically measures (1 back-and-forth motion) rolling width of solder on stencil. An alarm notifies the operator when resupply is needed to prevent missing resupply periods and eliminate irregular resupply timing.

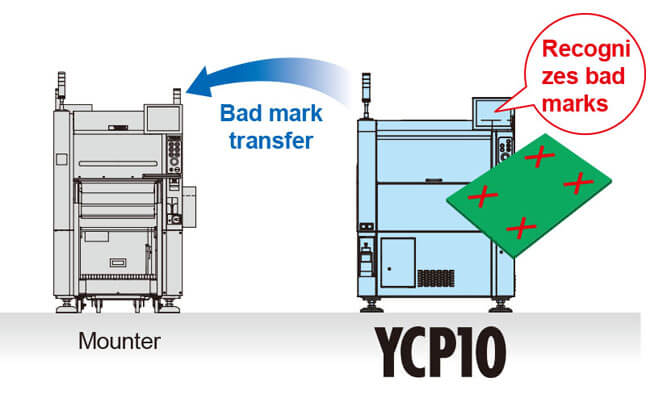

Bad mark transfer(Option)

Bad mark data recognized by the YCP10 is transferred to the mounter to drastically cut total line loss and boost production

YAMAHA SMT

High durability SMT products with “made-in-Japan” extra-high standards! YAMAHA makes the most of its stance as a “full lineup manufacturer” of mounting equipment including printers, dispensers, surface mounters, inspectors to offer a higher degree of efficiency and quality spanning the entire production line.

Specifications

| YCP10 | |

| Applicable PCB | L510 x W460mm to L50 x 50mm |

| Printing head | 3S head (3S : Swing Single Squeegee) |

| Double squeegee head (Option) | |

| Printing accuracy | Positioning repeatability (6σ) : +/- 0.010mm |

| Cycle time | 8sec (Standard printing : under optimum condition, except for printing time) |

| Applicable stencil size | L750 x W750mm, L736 x W736mm, L750 x W650mm, |

| L650 x W550mm, L600 x W550mm (Option), | |

| L550 x W650mm (Option), L584 x W584mm (Option) | |

| Power supply | Single-phase AC 200/208/220/230V +/- 20V 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension | L1,130mm x W1,760mm x H1,370mm |

| Weigh | Approx. 1,100kg |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky