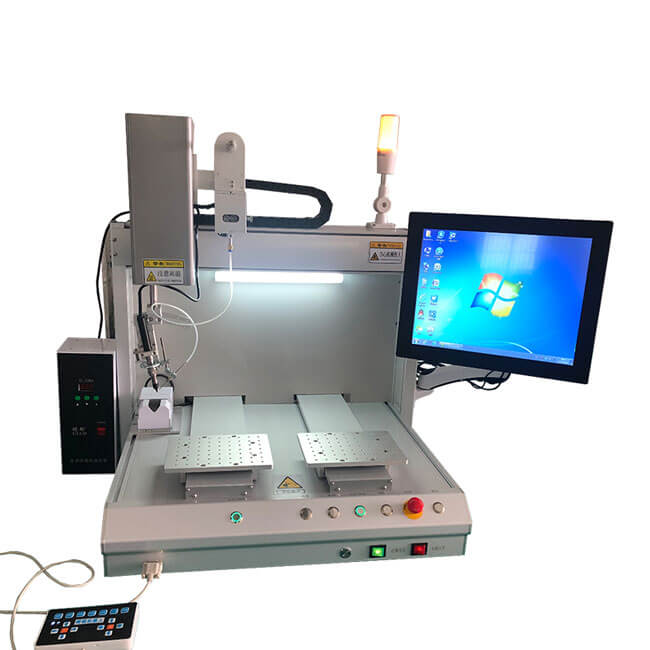

With computer version of automatic soldering machine

Functional features

1、Novel appearance of the machine, the main body using special surface treatment, beautiful and generous

2、New lean design, the same size brings greater effective travel.

3、Based on the Windows operating system development of user software, more consistent with the user's operating habits.

4、Real digital program, modify parameters directly input, the same tin point once change, insert point delete point a key operation.

5、12 "hd touch screen interface, dynamic display of running track;Make your soldering process more intuitive.

6、Can start tin feeding at any time, fully meet various soldering technology and improve machine efficiency, authority management mode, prevent operators from modifying parameters by mistake.

Solder joint type parameters flexible switching,

7、solder joint running speed can be set independently, do not affect each other.With the function of correction, the position deviation generated after the re-positioning of the mold can be corrected

8、The compensation point can be calculated automatically and can be compensated in any direction.

Support array mode, direct and short programming time, improve production efficiency,

File name can be freely created, copied, deleted and support English, numeric, character mixture

Standard hand held teaching device, programming is not limited by the screen, unlimited intelligence

9、Select 4G module, free lifetime remote upgrade.

10、High power high frequency heater with 350W, fast temperature return, ensure minimum temperature change during soldering.

11、Soldering can be started from any point, or separately soldering any point, no need to start welding from scratch.

specification

|

Name |

Computer version of the standard intelligent solder machine |

|

Number of equipment shaft |

4 axis +1 tin feed /5 axis +1 tin feed |

|

Device stroke (X*Y*Z*R)mm |

350*350*100*340° 500*350*100*340° |

|

Operating speed (X/Y/Z/R) |

X/Y/Z:500mm/s R:180°/s |

|

Repeated positioning accuracy |

±0.02mm |

|

Equipment load |

10KG |

|

Program recording capability |

unlimited |

|

Display mode |

12 "LCD display |

|

Mode of operation |

Touch screen + handheld teaching device |

|

The motor system |

Stepper motor/closed-loop stepper motor/servo motor |

|

Temperature range |

100℃~480℃ |

|

Tin system |

Independent drive + stepper motor |

|

Minimum length of tin feed |

0.1mm |

|

Applicable tin wire range |

0.6 ~ 1.6mm (other specifications can be customized) |

|

Input power |

220V AC/50HZ |

|

Air pressure |

0.4 ~ 0.8mpa, clean and dry |

|

Work environment |

0 ~ 40℃, humidity 20% ~ 95% (no condensation) |

|

Machine size mm |

(W*D*H)650*650*900/(W*D*H)650*750*900 |

|

Machine weight |

80KG/100KG |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky