VISCOM iS6059 3D SPI Machine

Viscom’s powerful SPI system inspects solder paste application in SMD production with maximum speed and precision. 3D features, such as volume, height, and shape as well as surface area, displacement, and smearing are accurately examined. The 3D inline system demonstrates decades of Viscom's experience in reliable, high-throughput solder paste inspection. The latest sensor technology with an orthogonal camera and four lateral views results in the highest inspection quality. Realistic color images ensure quick and clear verification. The FastFlow handling guarantees an extremely high throughput thanks to synchronous in- and outfeed of the assemblies. The system can achieve minimal handling times with minimal mechanical impact loads. Intelligent networking in the SMT line enhances process stability and efficiency.

ADVANTAGES AT A GLANCE

Latest 3D camera technology

Ultra-fast inspection – also with dual-lane operation

Shadow-free, seamless solder paste inspection

Closed loop functions with solder paste printer and pick-and-place machine

Effective process control and optimization in real time

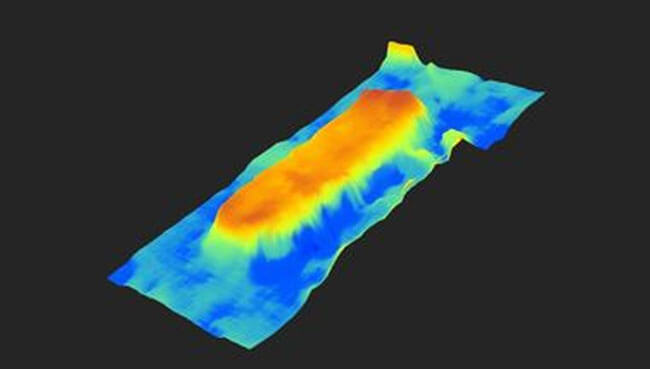

Color-assisted 3D solder paste volume calculation

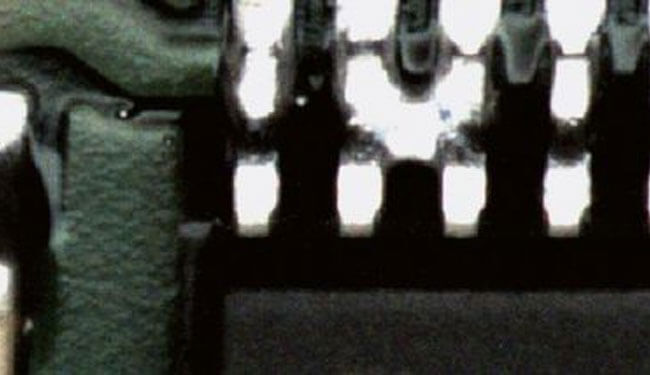

Paste bridge after soldering

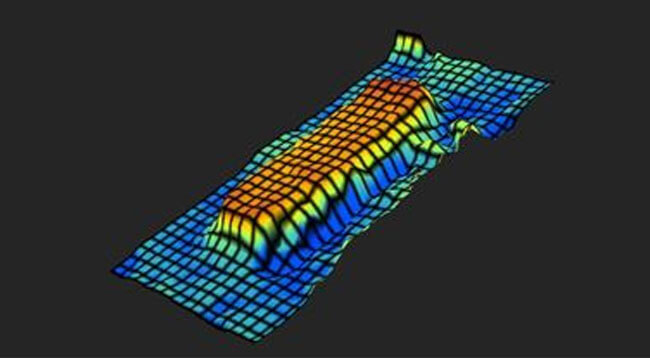

3D solder paste volume calculation with grid pattern

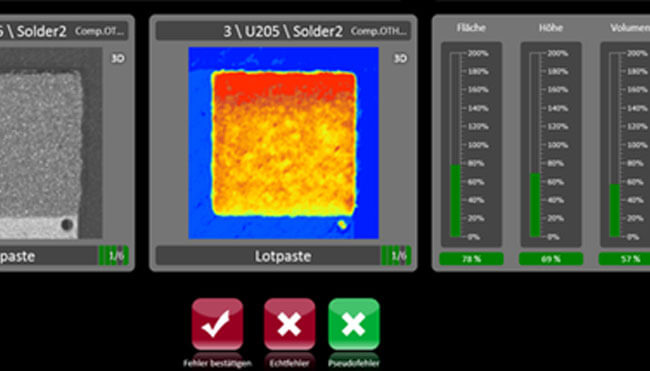

User-friendly overviews in vVision

HIGHLIGHTS

Excellent defect identification for ultimate reliability

Cutting-edge 3D camera technology

High inspection speed

Fast handling of PCBs

End-to-end process analysis with Viscom Quality Uplink

Closed-loop functions enhance quality and efficiency

Integrated verification

Flexible integration into existing productions

Improved ergonomic design

CONNECTIVITY

Global libraries, global calibration: transferability to all systems

Traceability, offline programming, statistical process control

Viscom Closed Loop: Intelligent communication between Viscom inspection systems and the paste printer and placement machine

Independent real-time image processing with Viscom analysis tools

Simple process analysis

Optional connection to the digital multi-purpose platform vConnect

INSPECTION

Inspects solder paste deposits (pad sizes of 01005 components) and dispenser paste for surface, height and shape

Defects/defect features: too much/too little solder, missing solder, print displacement (X/Y offset), paste smearing

Optional: coplanarity, open area analysis, OCR, DMC

|

Specifications |

|

|

size |

|

|

System Shell: |

997 mm x 1756 mm x 1753 mm |

|

|

(39.3" x 69.1" x 69") (W x L x H) |

|

Camera Technology |

XM Solder Paste Inspection |

|

3D sensor technology |

|

|

Z Resolution: |

.1 µm |

|

Z Range: |

Max. 5 mm(.2") |

|

|

|

|

Tilt-angle camera |

|

|

Megapixel Camera: |

4 |

|

|

|

|

Right angle camera |

|

|

Resolution: |

12 µm |

|

Field of view: |

58 mm x 58 mm(2.2" x 2.2") |

|

|

|

|

Detection speed |

Up to 80 cm²/s |

|

|

|

|

deal with |

|

|

PCB (Printed Circuit Board) Size: |

508 mm x 508 mm (20" x 20") |

|

|

|

|

software |

|

|

user interface: |

Viscom vVision |

|

Statistical process control: |

Viscom vSPC / SPC, open interface (optional) |

|

Verify the repair station: |

Viscom vVerify |

|

Remote Diagnosis: |

Viscom SRC (optional) |

|

Programming Station: |

Viscom PST34 (optional) |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky