OMRON VP9000 3D SPI Machine

The VP9000, is High Performance cutting-edge solution designed to minimize waste in PCB production while advancing towards smaller and higher density components. This state-of-the- art system enhances inspection efficiency through innovative 3D image processing and industry- leading high-speed inspection capabilities. The VP9000's distinctive Smart SMT Style not only analyses but also optimizes printing conditions, offering the highest performance to effectively prevent printing defects for a seamless production process.

High-Speed 100% 3D Solder Paste Inspection including 12MP camera

Highly Accurate Solder Paste Volume Measurement (within 2%)

Multiple Resolution Setting with 3-Mode Zoom Function (down to 5µm)

User-Friendly Software with Integrated, Graphical Use Interface

Simple Program Creation from GERBER and or Mount Data (compatible with ePM)

Complete Offline Program Generation without Interrupting Production.

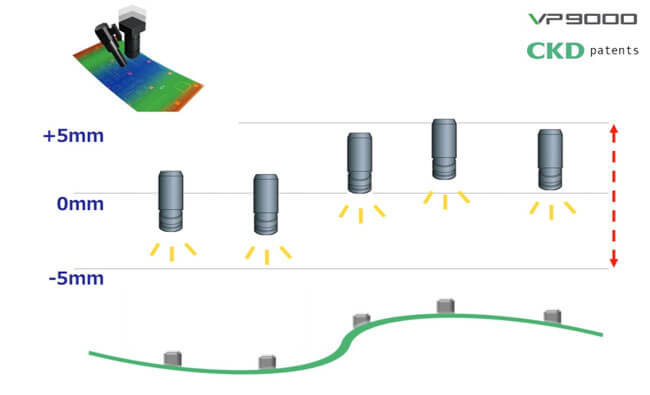

Active Warp compensation

Closed-loop with printer and feed-forward with Placement systems

Dual lane SPI available soon end of 2024

Glue and Foreign Material Inspection.

Unique Connection to: Omron Q-upNavi: Combine Omron SPI, AOI and AXI Result Data Together for True Root-Cause Analysis.

Unique Connection to: Omron Q-upOpti: Skill-less SPI Setting and Optimisation calculated from AOI Solder Values.

Unique Connection to: Omron Q-upAuto-I: Production Quality Analysis across your Entire Production Line.

The VP9000 touch-screen, color interface and fluid 2D/3D modeling provides operators immediate, interactive inspection result feedback. Inspection results can be reviewed while the next PCB is being inspected to improve productivity. The advanced data analysis software provides comprehensive quality data for continuous manufacturing process improvement and trend monitoring.

specification

| Inspection Method | Phase Shift Method |

| PCB Size | (M)50 x 50mm~330 x 250mm |

| (L)50 x 50mm~510 x 460mm | |

| PCB Thickness | 03~5.0mm |

| Accuracy (volume 3σ) *1 | Within 2% |

| PCB Warping Compensation | ± 5mm |

| Outline Dimensions | (M)724x970x1500mm |

| (L)904x1180x1600mm | |

| Power Supply | Single Phase AC200~230V 50~60Hz MAX 1KVA |

| Pneumatic Supply | Not Required |

| Weight | (M)460kg |

| (L)550kg | |

| UPS | Standard Equipment (only PC) |

| Environmental Standard | RoHS |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky