VISCOM iS6059 3D AOI Machine

iS6059 PCB Inspection Plus: Smartly networked with exceptional computing power and reliable measurement accuracy

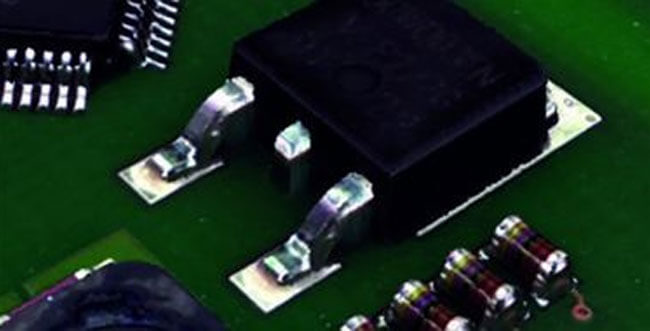

The iS6059 PCB Inspection Plus system rapidly checks that electronic components are in place, takes exact measurements of the heights on an assembly and inspects solder joints with high reliability. Nine views in first-class resolution and up to 26% more pixels, variable illumination, larger angled image fields with the same resolution, even further increased data transfer rates combined with 25% faster image capture and extensive networking options provide a solid basis for unbeatable line-integrated performance. Processes can be significantly improved and returns consistently avoided. Manufacturing costs can be trimmed in the long term and the high quality of even very sophisticated electronic products can be ensured.

ADVANTAGES AT A GLANCE

Effective process optimization and avoidance of returns

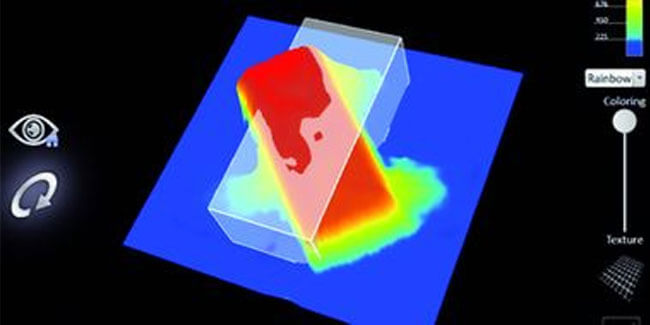

Latest 3D camera technology with XMplus-II sensor module

High depth of field from every angle

Variable illumination and larger angled fields of view at the same resolution

Complete 360-degree views in 3D

Higher data transfer rates with up to 25% faster image capture

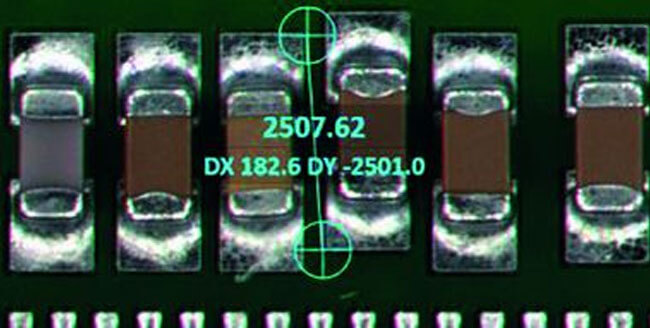

Exact height measurements of the smallest components

Comprehensive networking options (vConnect, IPC/CFX, Hermes, and more)

Inspection scope

Simple measurement of standards and exceptional cases

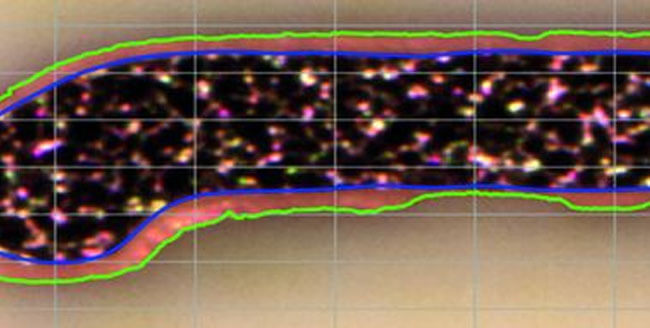

Inspection of cut voids using a combined 2D, 2½D and 3D approach

Complete rendering with 360View for verification tasks

Component body detection using 3D methods

HIGHLIGHTS

Uncompromisingly good imaging thanks to state-of-the-art sensor technology

High resolution for the precise inspection of microscopic components

Large angled views for the most accurate analyses

Smart verification with optional AI integration

Intuitively simple operation and creation of inspection programs

Fast data processing with powerful frame grabber

Extremely fast handling of the inspection objects

Expert service worldwide – online, by phone and on site

CONNECTIVITY

Global libraries, global calibration: importability to all systems

Traceability, offline programming, statistical process control

Autonomous Viscom real-time image processing with analysis tools

Simple process analysis with the Viscom Uplink Analyzer

INSPECTION

Solder joints, placement, open surfaces, character recognition, solder paste, configuration, assembly defects

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky