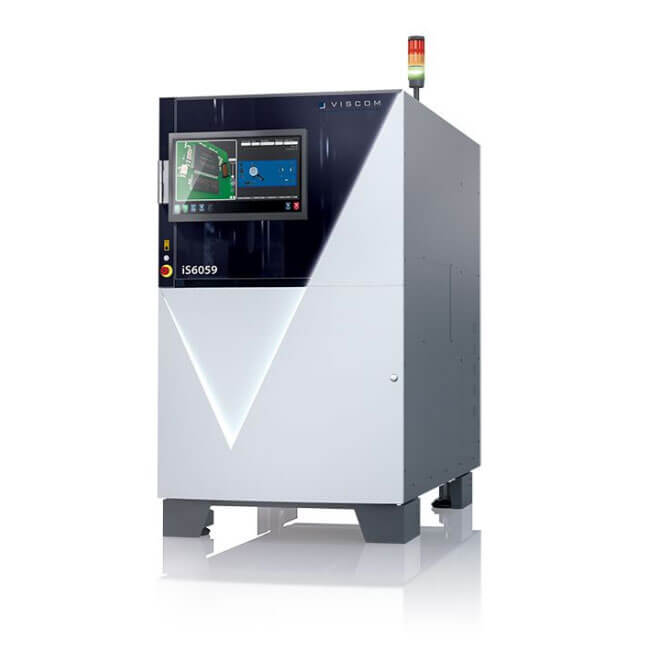

VISCOM iS6059 PCB 3D AOI Machine

iS6059 PCB Inspection – first-class inspection results for efficient SMT manufacturing

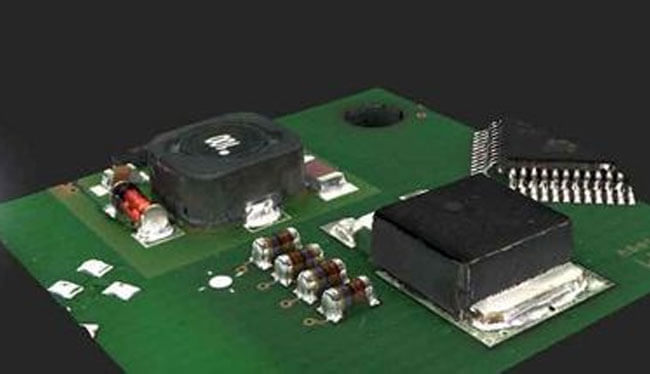

The iS6059 PCB Inspection combines the advantages of special high-speed 3D camera technology with excellent inspection quality and extremely fast inspection speed. The 3D AOI system, which was developed for the economical large-scale production of assemblies, reliably inspects both components and solder joints. Within the manufacturing process, it can be intelligently networked for Industry 4.0 applications.

Advantages at a glance

IPC-compliant 3D assembly inspection

Designed specifically for cost-effective mass production

Meets the most demanding cycle time requirements

Integrated verification for fewer false calls

Inspection scope

Realistic inspection images with 360View

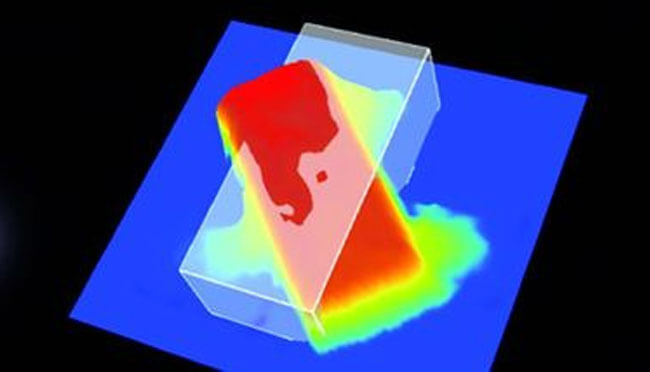

Reliable detection of defects such as tombstoning

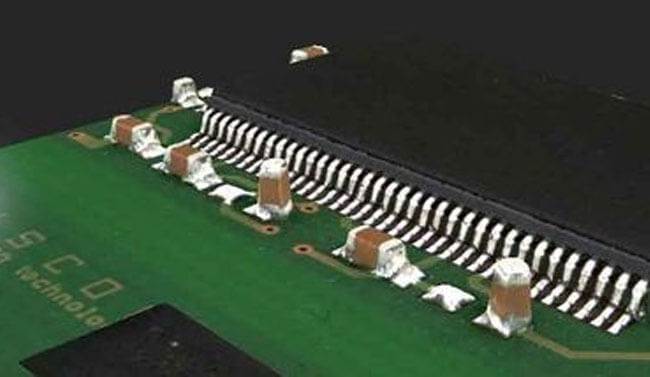

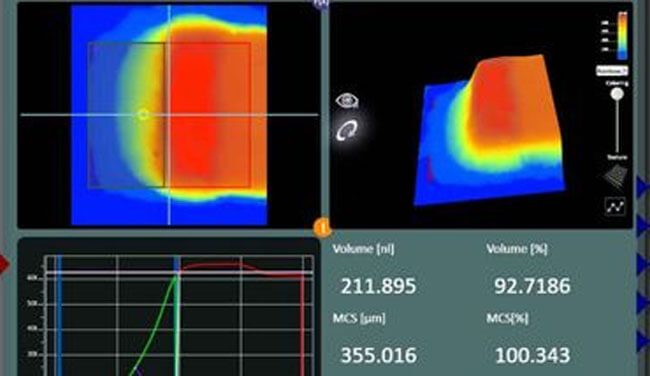

3D solder joint measurement

Component body detection using 3D methods

HIGHLIGHTS

Robust system design

Ideal system configuration with respect to costs/benefits

High inspection speed

One orthogonal camera and eight angled-view cameras provide virtually shadow-free 3D inspections

Verified zero defect slippage thanks to integrated verification

Flexible integration into existing productions

Improved ergonomic design

CONNECTIVITY

Global libraries, global calibration: transferability to all systems

Intelligent software add-ons such as integrated verification or Viscom Quality Uplink for effective networking

Traceability, offline programming, statistical process control

Communication with MES systems

Independent real-time image processing with Viscom analysis tools

High-performance OCR software

optional connection to the digital multi-purpose platform vConnect

INSPECTION

Components: up to 03015 and fine-pitch components

Solder paste, solder joint and assembly control

Defects/defect features: excessive/insufficient solder, missing solder/solder skip, component missing, component offset, wrong component, component damaged, component overpopulated, billboarding, component on back, damaged pin, bent pin, solder bridging/short circuit, tombstoning, lifted lead, soldering defects, nonwetting, contamination, polarity error, rotation, imperfect shape

Optional: free area analysis, color ring analysis, wobble circle error, OCR, blow holes in the solder joint, solder ball/solder sputter

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky