MIRTEC GENESYS-CC 3D AOI Machine

The GENESYS-CC AI Based Conformal Coating AOI Series represents a monumental advancement in inspection technology, pushing the boundaries of conformal coating inspection within the electronics manufacturing industry. Powered by MIRTEC's Exclusive 15MP CoaxPress Camera Technology, complemented by four 18MP Side-Angle Cameras, this series also offers an optional Internal PCB Flipper Conveyor designed for Double Sided PCB Inspection.

This cutting-edge series leverages the prowess of artificial intelligence (AI), delivering unmatched precision and accuracy in the inspection of conformal coatings on printed circuit boards (PCBs). Advanced AI algorithms meticulously analyze coating thickness, coverage, and uniformity, ensuring optimal protection for sensitive electronic components. With high-resolution cameras and intelligent software, the GENESYS-CC Series swiftly identifies defects and anomalies, enhancing inspection speed and efficiency, and reducing the risk of coating failures. This guarantees superior product quality.

exclusive 15 Megapixel CoaXPress High-Speed Camera System, a Precision 10µm Telecentric Lens, and an Advanced Eight (![]() Phase RGB / UV Lighting System. This extraordinary system is available with a Programmable Multi-Focus Z-Axis System for the Inspection of taller devices and an Internal PCB Flipper Option to inspect double-sided PCBs.

Phase RGB / UV Lighting System. This extraordinary system is available with a Programmable Multi-Focus Z-Axis System for the Inspection of taller devices and an Internal PCB Flipper Option to inspect double-sided PCBs.

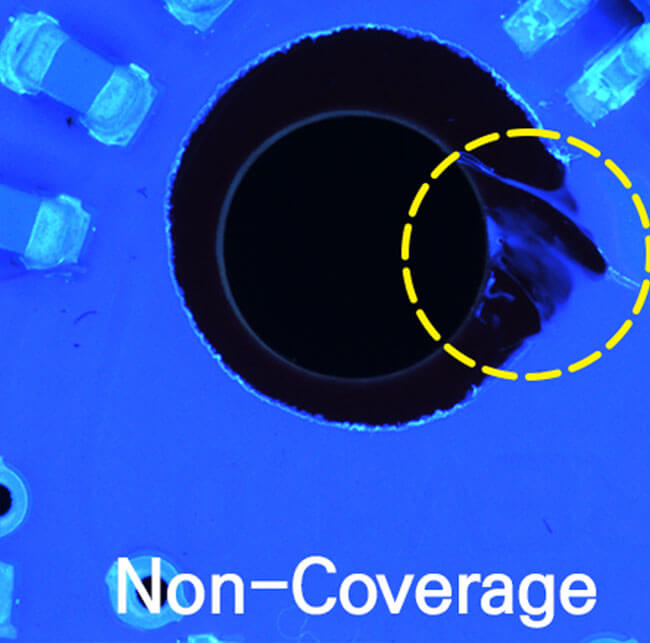

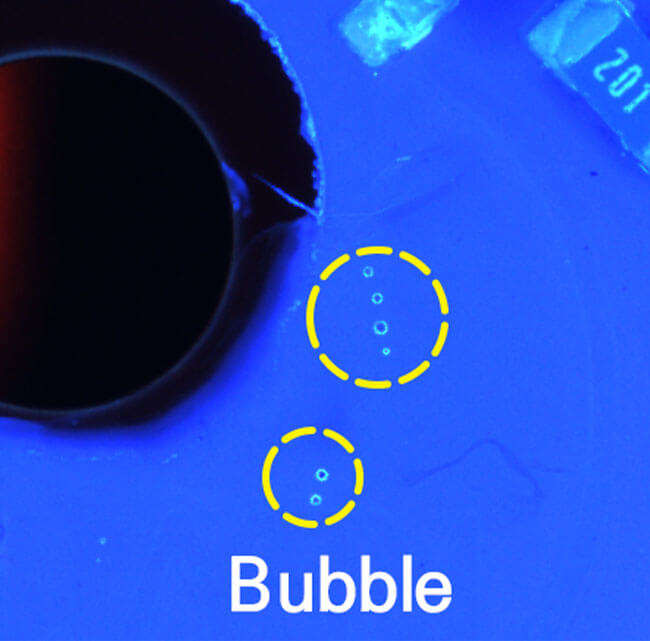

The GENESYS-CC can detect Conformal Coating defects such as bubbles, coverage, and non-coverage with extreme accuracy. Additionally, it offers the option of four (4) 18 Megapixel Side Cameras for lateral CC Inspection. This multi-purpose inspection machine is capable of both Conformal Coating Inspection and full 2D AOI for assembled PCBs.

3D/2D Coating Inspection

15M high speed camera

Deep learning based AI bubble inspection

Coating thickness inspection

Double sided PCB inspection with built-in flipper

Precise mark recognition with coaxial light

GENESYS-CC is specifically developed for conformal coating inspection. GENESYS-CC can detect conformal coating defects such as bubbles, coverage, and non-coverage with extreme accuracy.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky