VISCOM iS6059 3D THT AOI Machine

iS6059 THT Inspection – unmatched 3D AOI for underside quality control

With innovative 3D camera technology, the iS6059 THT Inspection 3D AOI system inspects THT components, THT solder joints, press-fit and SMD components shadow-free and at high precision on the underside of the printed circuit board. PCBAs as well as inspection objects on workpiece carriers are inspected at high speed in 2D, 2½D and 3D. As a result, the iS6059 THT Inspection stands for maximum defect detection and highest throughput. Different lighting can be used flexibly and so provide inspection results in excellent quality.

ADVANTAGES AT A GLANCE

Maximum defect detection

Flexible handling options

Unmatched 3D camera technology

Different illuminations

Complete process tracking

Inspection scope

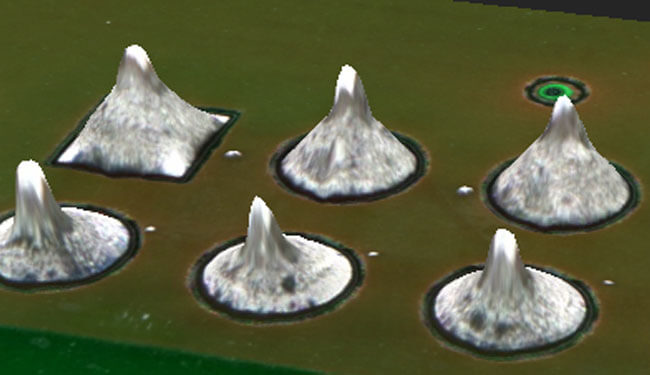

Height profiles of THTs

Insufficient wetting (front) and missing pin (back)

Reliable 3D pin length inspection

3D quality control of THT solder joints

HIGHLIGHTS

Maximum performance: Featuring a powerful 3D XM sensor system concept for performing quality inspections from below

First-rate inspection quality: Shadow-free inspection thanks to 8 angled cameras

System flexibility: reliable handling of a wide range of different inspection objects

Optimum process design due to extended handling possibilities such as long board option

Minimal time and training requirements thanks to Viscom standard software

Flexible integration into existing productions

Improved ergonomic design

CONNECTIVITY

Global libraries, global calibration: Transferability to all systems

Outstanding inspection program optimization thanks to flexible single and multiline verification solutions

Simple operation and inspection program generation with EasyPro/vVision

High-performance OCR software

Connection via horizontal interfaces along the production line

Viscom Quality Uplink: intelligent networking of Viscom inspection systems along the production line

Production line control and product traceability

Flexible integration of additional production-relevant modules: buffers, label printers, etc.

Connection to vertical interfaces for communication with MES systems

Statistical process control with Viscom SPC/vSPC

Offline programming stations for increased efficiency

Optional connection to the digital multi-purpose platform vConnect

INSPECTION

Components: THT, press-fit and SMD

Solder joints: 3D inspection of PCB bottom sides after wave soldering or selective soldering

Defects/characteristics:

SMD: Presence, XY position, rotation, component height, polarity, missing solder, soldering defects, lifted heads/tombstoning, bridging

THT: Presence, XY position, missing solder, soldering defects, bridging, pin height, non-wetting on pins, non-wetting on pads

Optional: Free area analysis, wobble circle error, color ring analysis, OCR, blow holes in the solder joint, solder ball/solder sputter

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky