VISCOM S3088 ultra chrome 3D AOI Machine

S3088 ultra chrome: maximum inspection results for efficient SMT fabrication

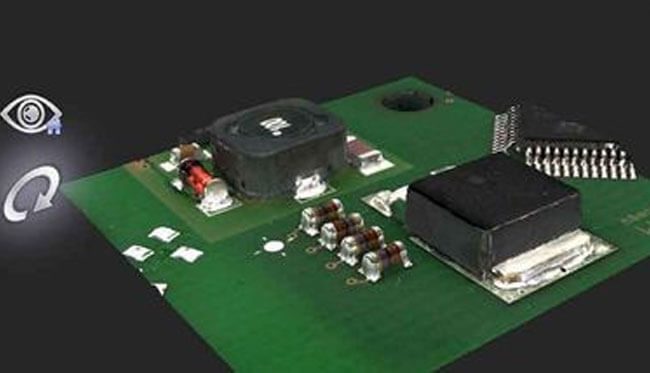

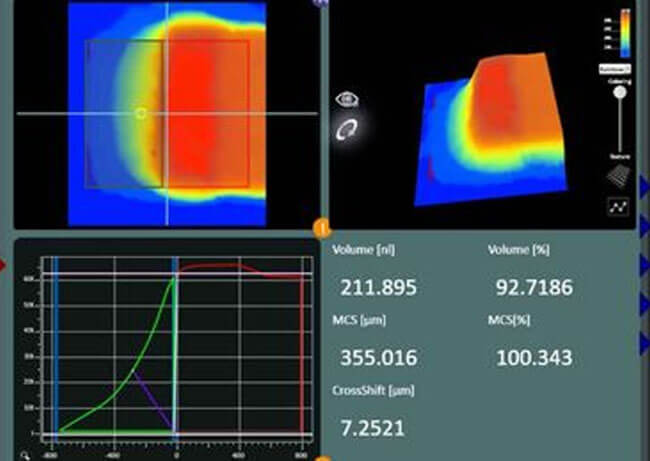

Viscom has developed a best-of system configuration on the basis of the successful, flexible S3088 ultra premium system. Outstanding inspection quality and extremely fast inspection speed are combined in a compact housing design with special high-speed 3D camera technology. Developed for cost-effective mass production of printed circuit boards, the S3088 ultra chrome offers reliable component inspection and measures solder joints at a resolution of 10 µm. The 3D AOI system can be intelligently networked within the production process via Quality Uplink for Industry 4.0 applications.

Advantages at a glance

IPC-compliant 3D assembly inspection

Designed specifically for cost-effective mass production

Meets the most demanding cycle time requirements

Integrated verification for fewer false calls

Inspection scope

Realistic inspection images with 360View

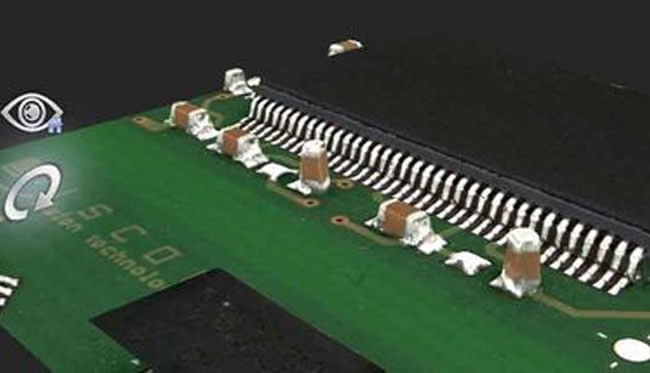

Reliable detection of defects such as tombstoning

3D solder joint measurement

HIGHLIGHTS

Space-saving system design

Ideal system configuration with respect to costs/benefits

Rapid inspection speeds of up to 65 cm²/s

One orthogonal camera and eight angled view cameras provide virtually shadow-free 3D inspections

Verified zero defect slippage thanks to integrated verification

CONNECTIVITY

Global libraries, global calibration: transferability to all systems

Intelligent software add-ons such as integrated verification or Viscom Quality Uplink for effective networking

Traceability, offline programming, statistical process control

Communication with MES systems

Independent real-time image processing with Viscom analysis tools

High-performance OCR software

INSPECTION

|

Components: |

03015 components and fine pitch parts |

|

Solder paste, solder joint and patch inspection |

|

|

Defects/Features: |

Too much/not enough solder, missing solder, missing parts, misplaced parts, wrong parts, damaged parts, over-assembly of parts, parts lying on their sides, parts lying on their backs, damaged pins, bent pins, solder bridges/shorts, tombstoning, lifted pins, soldering defects, wetting, dirt, wrong polarity, deflection, wrong shape |

|

Optional: |

Blank area analysis, color ring analysis, bevel circle defects, OCR, voids in solder joints, solder balls/tin slag |

SPECIFICATIONS

|

Specifications |

|

|

size |

|

|

System Shell: |

994 mm x 1565 mm x 1349 mm (W x H x D) |

|

Detection |

|

|

Sensing system: |

XMs |

|

Inspection method: |

2D, 2.5D, 3D AOI |

|

Megapixels: |

Maximum total quantity 65 units |

|

Oblique Angle Camera: |

8-megapixel camera |

|

Orthographic camera resolution: |

10 μm |

|

Image field size: |

50 mm x 50 mm |

|

Detection speed: |

Up to 65 cm²/s |

|

deal with |

|

|

Board size: |

508 mm x 508 mm |

|

software |

|

|

Operation interface: |

Viscom vVision/EasyPro |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky