UNICOMP AX9100 Max X-ray Inspection Machine

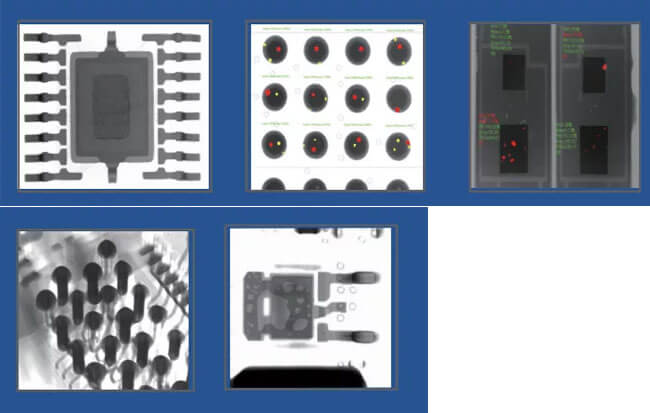

Widely applied for BGA , CSP , Flip Chip, LED , Fuse,Diode, PCB, Semiconductor, Battery Industry, Small Metal Casting, Electronic Connector Module, Cables, Photovoltaic Industry, etc.

Application Fields

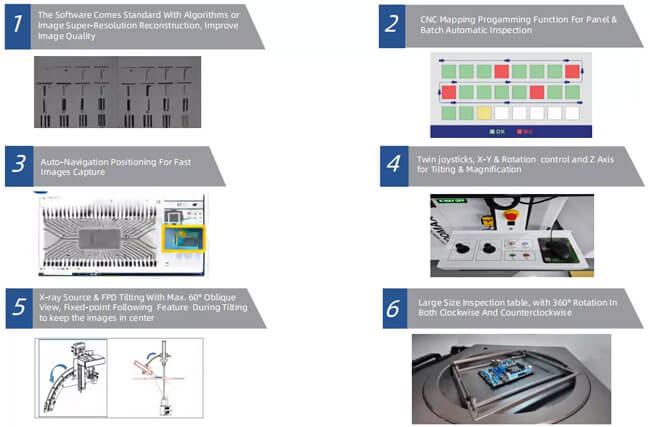

Functions and Features

Inspection Image

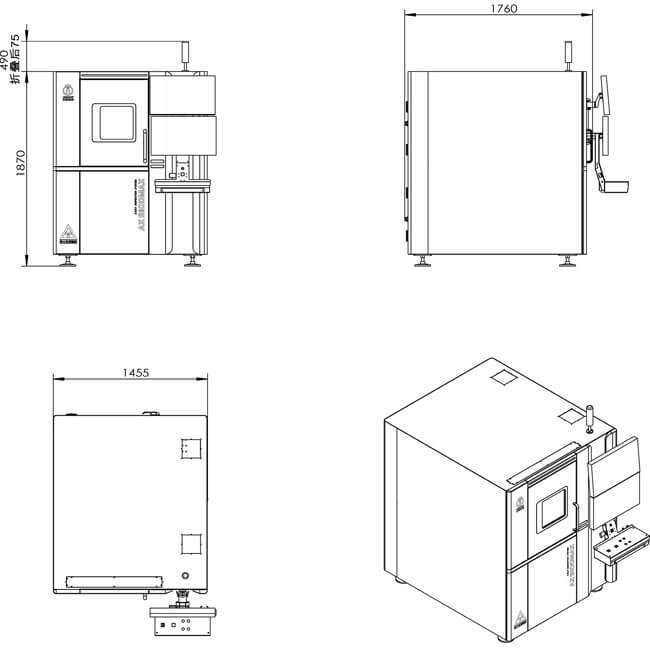

Dimensions and Appearance

|

System Summary |

|

|

Footprint |

1455(W)×1760(D)×1945(H)mm |

|

Machine Weight |

2400 kg |

|

Power Supply |

AC 110~220V, 50/60Hz |

|

Packaging Dimension |

2280(W)×1750(D)×2100(H)mm |

|

Packing Weight |

2600 kg |

|

Power Consumption |

4 kW |

|

X-Ray Tube |

|

|

Tube Type Type |

Sealed type |

|

Max. Power Output |

65W |

|

Voltage |

0~130kV (Adjustable) |

|

Focus Spot Size |

≤7μm |

|

Imaging System |

|

|

Detector |

High Resolution FPD |

|

Pixel Size |

84μm |

|

Effective Detection Area |

129*129mm |

|

Frame Rates |

20fps |

|

Pixel |

1536*1536 |

|

System Magnification |

1600X |

|

Software |

|

|

One-click Zoom in & out |

Fast & Automatic navigation of ROI region |

|

Fixed-point following during FPD tilting |

Table automatic following while Axis tilting seperately |

|

Algorithms For Image Super-Resolution Reconstruction |

Intelligently improve the overall image clarity with one-click |

|

Automatic images comparison |

Intelligently adjust overall image contrast with one-click |

|

Variety of filter processing algorithms |

Sharpening, enhancement, color reversal, denoising image preprocessing functions |

|

Motion Control System |

|

|

Movement Control Method |

Dual Joystick, Keypad & Mouse |

|

Max. Loading size |

Ф620mm |

|

Max. Inspection size |

600*450mm |

|

Tilting Inspection |

Maximum 60°(Tube & Detector) |

|

Objective Stage |

Horizontal Rotation 360° |

|

Industrial PC |

|

|

Monitor(Dual) |

27 "4K HD display |

|

Operating System |

Windows 10 64 |

|

Hard disk |

1TB |

|

RAM |

16G |

|

CPU model |

i7 |

|

Other Features |

|

|

Door Open |

Manually |

|

Safety Operation |

Electromagnetic Interlock, Warning Light and Real-time Radiation Leakage Monitor |

|

Authority Management |

Fingerprint Access Management System, and Support Password Accessing |

|

X-Ray Safety |

<1μSv/h |

|

(Meets All International Standards) |

|

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky