UNICOMP AX8200 X-ray Inspection Machine

Lithium battery pole piece solder joint defect detection,

Lithium battery batteries coiling case detection,

BGA, CSP , LED , Flip Chip , Semiconductor,

Battery Industry,Small Metal Casting,

Electronic Connector Module,

Aerospace Components , Photovoltaic Industry,

Other Special Industries.

Application

Lithium battery pole piece solder joint defect detection,

Lithium battery batteries coiling case detection,

BGA, CSP , LED , Flip Chip , Semiconductor,

Battery Industry,Small Metal Casting,

Electronic Connector Module,

Aerospace Components , Photovoltaic Industry,

Other Special Industries.

Features

●Large Size Inspection Table, Laser Locator for Precise Location

●±60° Oblique Views Table

●Pseudo 3D Function

●CNC Programming, Automatic BGA Voids Measurement, Results Can be Exported

●Mark Irregular Graphics

●Safety Electromagnetic Interlock

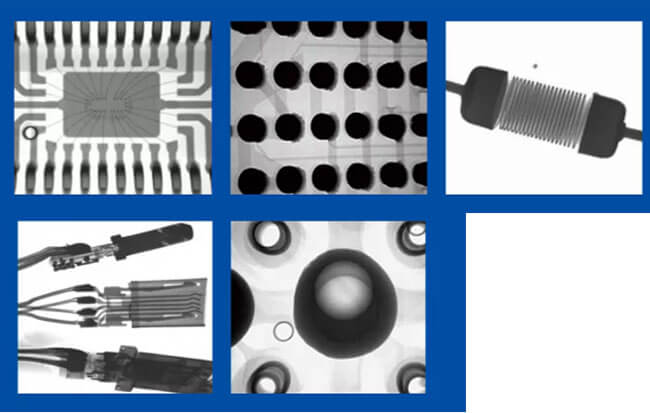

X-Ray Images

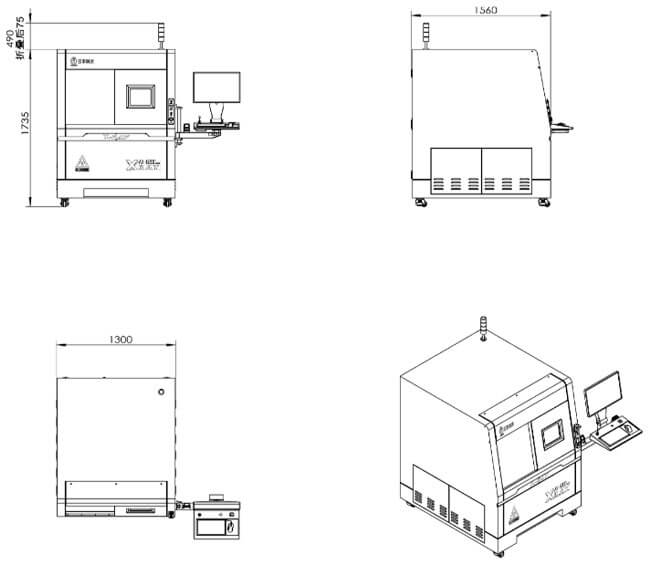

Dimensions and Appearance

| System Summary | |

| Footprint | 1090(W)×1265(D)×1810(H)mm |

| Machine Weight | 1000 kg |

| Power Supply | AC 110~220V, 50/60Hz |

| Plywood Packing Size | 1500(W)×1300(D)×1950(H)cm |

| Packing Weight | 1050 kg |

| Power Consumption | 1.5 kW |

| X-Ray Tube | |

| Tube Type | Sealed |

| Max. Power | 8W |

| Voltage | 0~90kV (Adjustable) |

| Focus Spot Size | 5μm |

| Imaging System | |

| Detector | Flat Panel Detector |

| Pixel Size | 84μm |

| Effective Detection Area | 129*129mm |

| Frame Rates | 20fps |

| Pixel Matrix | 6lp/cm |

| System Magnification | 600X |

| Motion Control System | |

| Movement Control | Joystick, Keypad & Mouse |

| Max. Loading Area/Weight | 510*420mm / 10kg |

| Max. Inspection Area | 420*380mm |

| Oblique Views | Max. ±60° |

| Manipulator | 5-axis with X / Y / Z1 / Z2 |

| Industrial PC | |

| Monitor | 21.5’’ FHD LCD Display |

| System OS | Windows 10 64bit |

| Hard disk | 1TB |

| RAM | 8GB |

| CPU model | Intel i7 Processor |

| Other Features | |

| Energy Saving | X-Ray Auto-off when it's out of work over than 5 minutes |

| Safety Operation | Electromagnetic Interlock and warning Light |

| Portable Design | Mounted with Wheels on Machine Bottom |

| X-Ray Safety | <1μSv/h (Meets All International Standards) |

| * Specifications are subject to change without notice, All trademarks are the property of the system maker. | |

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky