Panasonic NPM-GW Pick and place machine

Key features and functions

Support large components and large PCBs to meet the increasing demand for Electric Vehicles (EV) and DX

5M process control “APC-5M” for good production and stable operation

Various skill-less and manpower-saving features including Auto Setting Feeder

* 5M: The variable elements of a production site: huMan, Machine, Material, Method, and Measurement

Features

Modular mounter with wide range of components/PCBs compatibility

The basic performance of this modular mounter has been improved by renewing the core units, such as the placement head and recognition camera. It now supports a wide range of components and various components supply configurations, and can also handle larger PCBs. It also supports various automation and manpower-saving functions, including the Auto Setting Feeder (ASF), which automates the components supply operation, to flexibly meet the requirements of each mounting site.

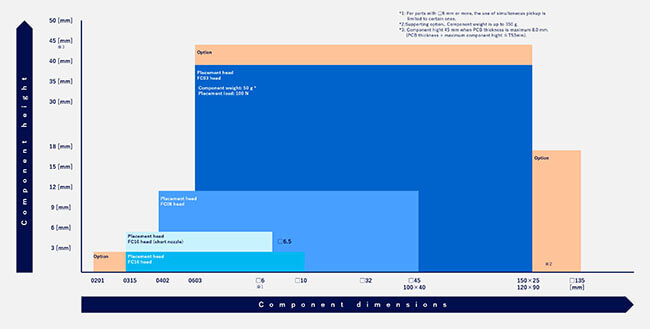

Supported components range

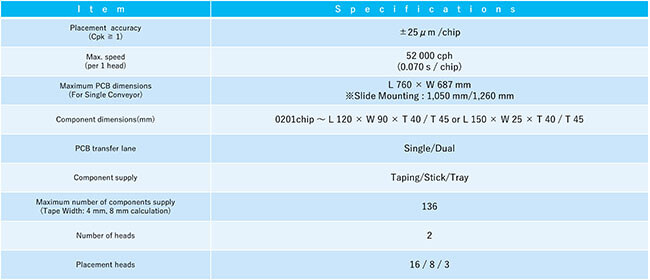

Maximum speed and placement accuracy

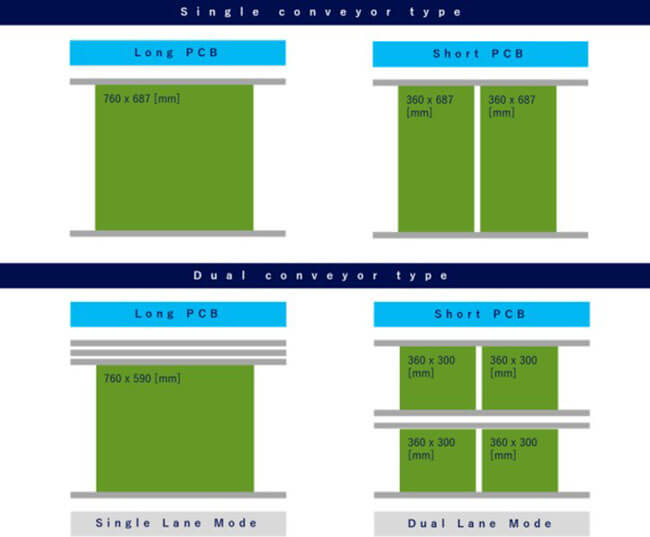

Supported PCB size

Configuration example

Example configuration

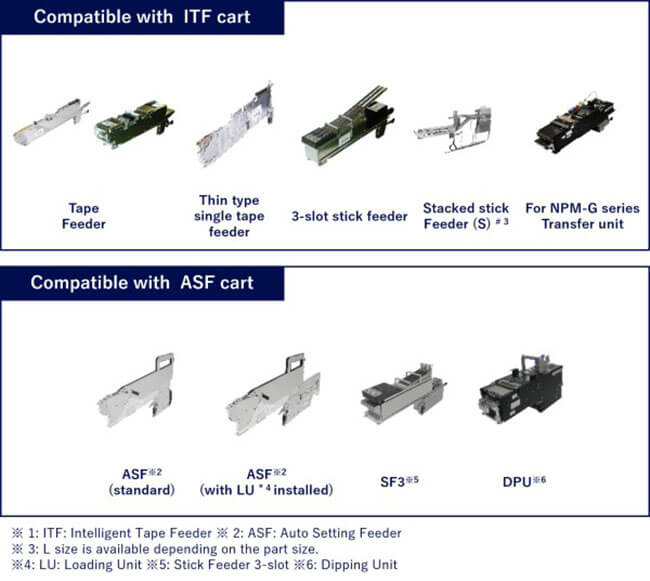

Component supply units

Wide variety of components

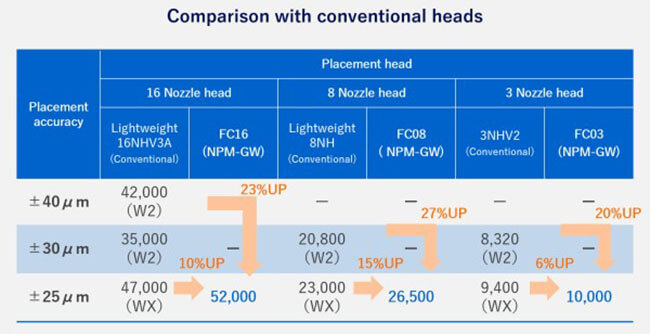

High productivity mounting of a wide range of components Placement head (new design)

Flexible head configuration for 0201 to large and tall components. Production can be performed with high productivity. When compared with the catalog speed (CPH), the NPM-GW is approximately 10% better than our conventional model NPM-WX at ±25μm condition.

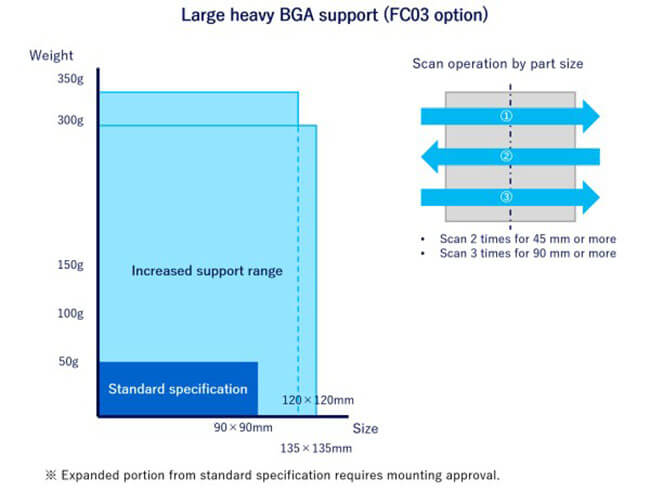

Large heavy BGA components

Large, heavy components placement

The nozzle is designed for large, heavy components, and scanning operations are tailored to the component size. And 15,000 BGA balls are detected, a trend in the server industry.

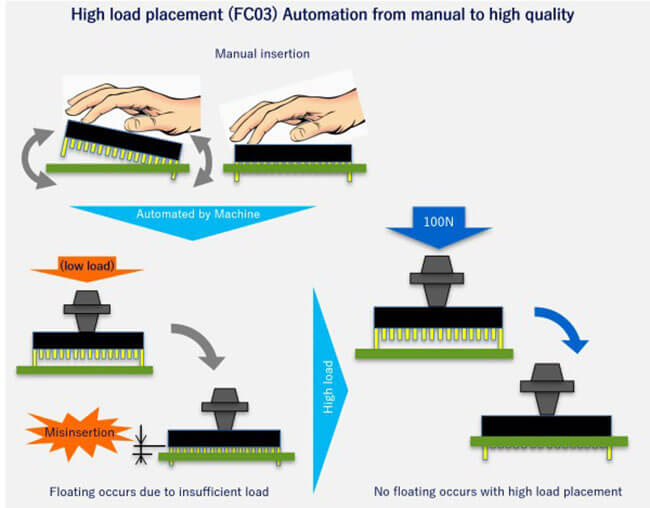

Automated DIMM connector placement

Automated DIMM connector placement

High load placement / Tall component mounting

High load placement of 100N is able to eliminate pin floating, and tall component mounting up to 53mm (including PCB thickness) allows automated DIMM connector placement. (*Please consult us for applicable components.)

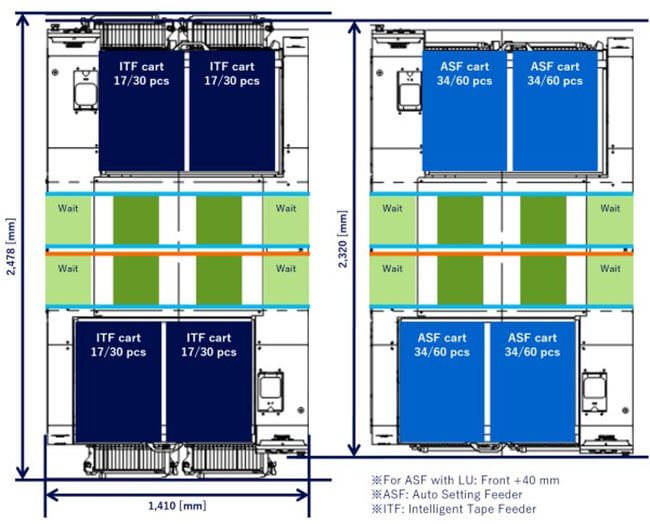

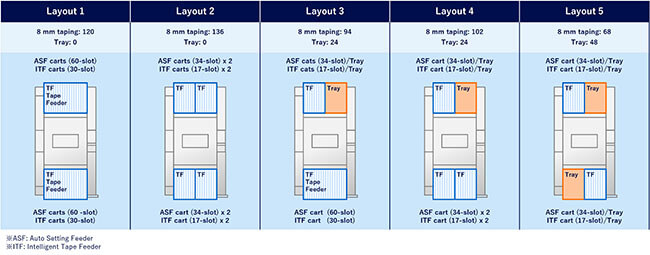

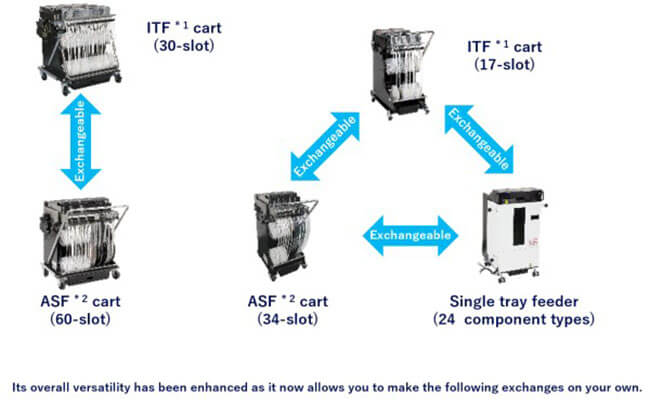

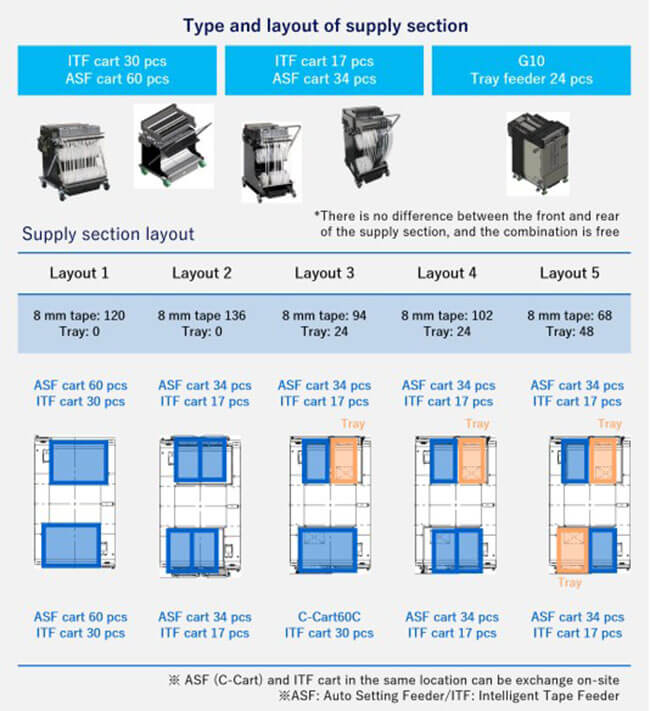

Adaptable to various supply section layouts

Three types of supply section units

By combining three types of supply section units, you can select a variety of supply section layouts.

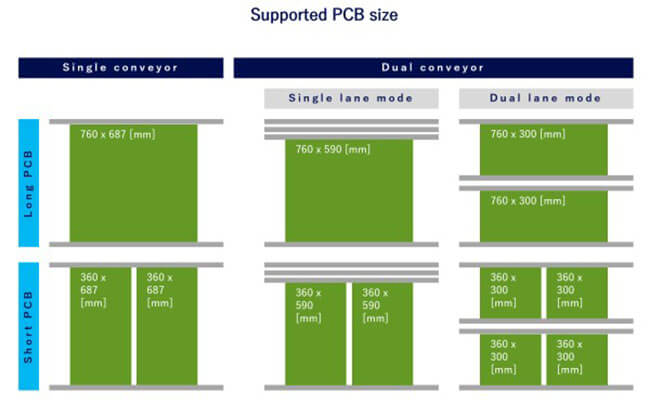

Wide range of PCB types and industries

Supported PCB sizes

The number of PCB sizes supported has been expanded from previous models to accommodate a wider range of PCB types, satisfying the needs of customers in a number of industries.

Support for large PCBs

When the transfer direction dimension (L) exceeds 760 mm, the supported PCB size can be expanded up to 1,050 mm. When equipped with a front/rear extension conveyor, it can be expanded up to 1,260 mm.

High quality placement

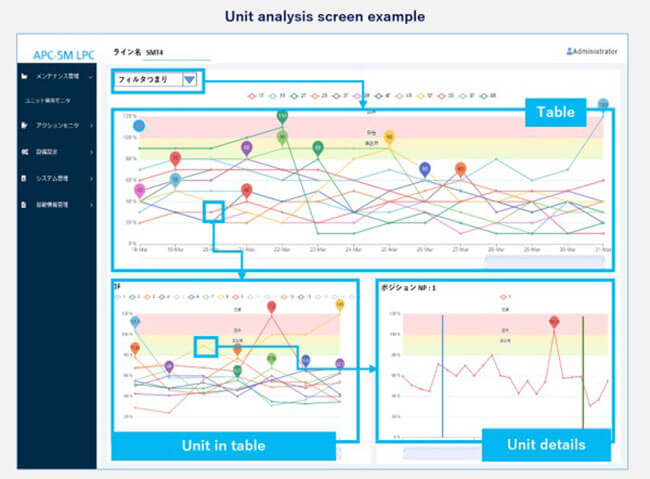

Unit condition monitoring~analysis to optimize maintenance APC-5M (option)

To ontrol 5M variation autonomously, unit condition can be monitored, analyzed easily to ensure proper maintenance.

5M Unit conditions are monitored in real time to control variations autonomously, enabling predictive maintenance before conditions deteriorate and preventing errors due to lack of maintenance.

Not only showing the status of each equipment, but also the entire line can be displayed on the LPC (Line Process Controller) screen for line status monitoring, and the status of target units in the line can be broken down for time-series analysis. The status after maintenance can also be checked to determine if maintenance is appropriate.

※5M : huMan, Machine, Material, Method, Measurement

| SKU | NM-EJM2F |

| Model ID | NPM-GW |

| Model No. | NM-EJM2F |

| PCB Dimensions (mm) | Single conveyor: |

| Batch mounting :L 50 mm × W 50 mm to L 760 mm × W 687 mm | |

| 2 position mounting : L 50 mm × W 50 mm to L 360 mm × W 687 mm | |

| Dual conveyor: | |

| Please refer to the specification booklet for details* | |

| Electric Source | 3-phase AC 200、220、380、400、420、480 V 2.5 kVA |

| Pneumatic Source | Min.0.5 MPa、200 L / min ( A.N.R. ) [*1] |

| Dimensions (mm) [*2] | W 1 410 mm × D 2 320 mm × H 1 444 mm[*3] / W 1 410 mm × D 2 468 mm × H 1 444 mm[*4] |

| Mass | 2 810 kg [*3] / 2 840 kg [*4] |

1. Only for main body

2. Excluding the monitor and signal tower

3. Machine dimensions and mass for standard configuration ( NPM-GW and ASF cart ( 60-slot ) × 2 or cart ( 34-slot ) × 4 ).They differ depending on the optional configuration.

4. Dimensions and mass of the machine and two ITF carts ( 30-slot ).

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky