Panasonic NPM-D3 Pick and place machine

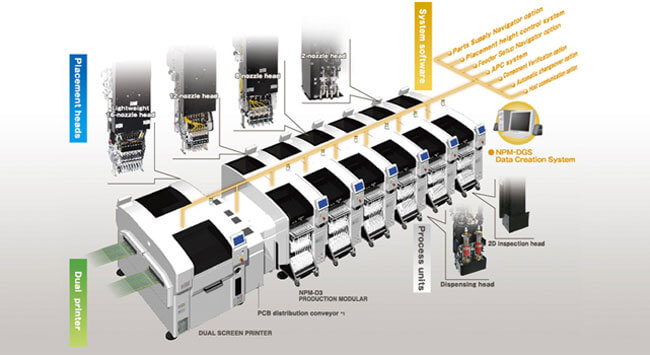

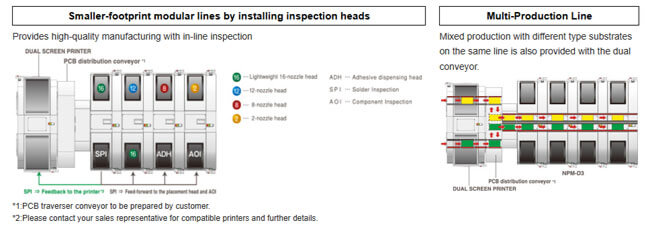

Panasonic NPM-D3 Electronic Production Modular is a new concept machine designed and manufactured by Panasonic according to electronic mounting changes. It integrated higher productivity and quality with printing, placement and inspection process. Configurable modules allow flexible line setup. Comprehensive control of electronics production lines, floor and factory with system software. It is the best choice for customers who require high production capacity, fast line transfer and wide variety of components.

Key Features

Single head (single beam) capable of placing an impressive component array including: 0402mm to 120x90x28mm

Capable of placing large connectors, odd-shaped components, and advanced packaging types such as PoP

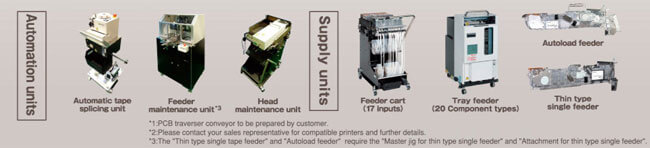

Interchangeable feeders, multi-functional nozzles, and chucks with the CM and NPM series

Cost-effective and high quality production

Total line solution

| Product name | Panasonic Chip Mounter NPM Series SMT Placement | ||||

| Model | NPM-D3 | NPM-W2 | NPM-TT2 | NPM-W2S | |

| Concept | Dual-gantry, multi-head, | Dual-gantry, multi-head, | Dual-gantry, multi-head, | Single-gantry, multi-head, | |

| process-driven module | process-driven module | process-driven module | process-driven module | ||

| Drive system | High-accuracy, low-maintenance, linear-motor driven gantry(s) system | ||||

| Component alignment | Multi-recognition digital camera | ||||

| Head design options | Inline array of 16, 12, 8, 3 and 2(D3) nozzle heads | ||||

| Applicable heads | 16, 12, 8, 2 | 16, 12, 8, 3 | 8, 3 | 16, 12, 8, 3 | |

| Board dimensions (Single lane) | L 510mm x W 590mm | L 750mm x W 550mm | L 510mm x W 590mm | L 750mm x W 550mm | |

| 1200mm long PCB opt | 1200mm long PCB opt | ||||

| Board dimensions (Dual lane) | L 510mm x W 300mm | L 750mm x W 260mm | L 510mm x W 300mm | L 750mm x W 260mm | |

| L 510mm x W 550mm *1 | L 750mm x W 510mm *1 *2 | L 510mm x W 550mm *1 | L 750mm x W 260mm *1 *2 | ||

| Placement accuracy | Chip | ±25μ Cpk ≥ 1.0 *4 | ±25μ Cpk ≥ 1.0 *4 | ±40μ Cpk ≥ 1.0 | ±25μ Cpk ≥ 1.0 *4 |

| QFP | ±30μ Cpk ≥ 1.0 | ±30μ Cpk ≥ 1.0 | ±30μ Cpk ≥ 1.0 | ±30μ Cpk ≥ 1.0 | |

| Throughput | Ideal | Up to 84,000 CPH | Up to 77,000 CPH | Up to 36,000 CPH | Up to 38,500 CPH |

| IPC9850 | 63,300 CPH (1608C) *3 | 59,200 CPH (1608C) *3 | 8,300 CPH (208 QFP) *3 | 30,000 CPH (1608C) *3 | |

| Component range | Min | 03015 microchip *4 | 03015 microchip *4 | 0402 microchip | 03015 microchip *4 |

| Max | 100mm x 90mm | 150mm x 25mm | 150mm x 25mm | 150mm x 25mm | |

| Height | 28mm | 30mm | 30mm | 30mm | |

| Special height | - | 40mm | - | 40mm | |

| Insertion force | .5N ~ 50N | .5N ~ 100N | .5N ~ 100N | .5N ~ 100N | |

| Feeder capacity | Reels w/ no tray feeder | 68 | 120 | 120 | 120 |

| Reels w/ tray tower | 24 | 86 | 86 | 86 | |

| Reels w/ twin tower | N/A | 60 | N/A | 60 | |

| Reels w/ 2 tray towers | N/A | N/A | 52 | N/A | |

| Trays w/ tray tower | 20 | 20 | 20 | 20 | |

| Trays w/ twin or 2 tray towers | N/A | 40 | 40 | 40 | |

| Facilities | Electric | Voltage: 3 Phase AC 200/220 ±10V; AC 380 400 420 480V ±20V Frequency: 50/60 Hz | |||

| 2.7KVA | 2.8KVA | 2.5KVA | 2.0KVA | ||

| Peak current 30A @ 200V | Peak current 40A @ 200V | Peak current 38A @ 200V | Peak current 22A @ 200V | ||

| Pneumatic | .5 ~ .8MPa, 100L/min | .5 ~ .8MPa, 200L/min | .5 ~ .8MPa, 200L/min | .5 ~ .8MPa, 200L/min | |

| Mass | 1900kg w/ 2 carts | 2850kg w/ 2 carts | 3090kg w/ 2 carts | 2850kg w/ 2 carts | |

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky