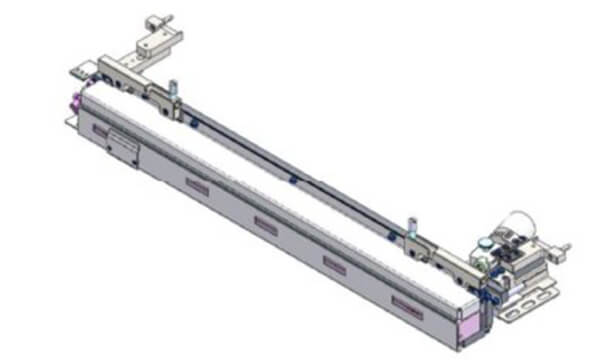

Panasonic NPM-GP/L Solder paste printer

The new NPM G Series

Industry's top edge class device

The high-precision NPM-GP/L stencil printer is part of the new NPM G Series to help making autonomous factories a reality. The NPM G Series offers flexibility and customisable options to address production needs and extend automation in manufacturing. This includes its auto setting feeder (ASF), NPM-GP/L stencil printer, and NPM-GH pick and place machine, allowing to set up individual, flexible, efficient, and economical production lines.

Key features

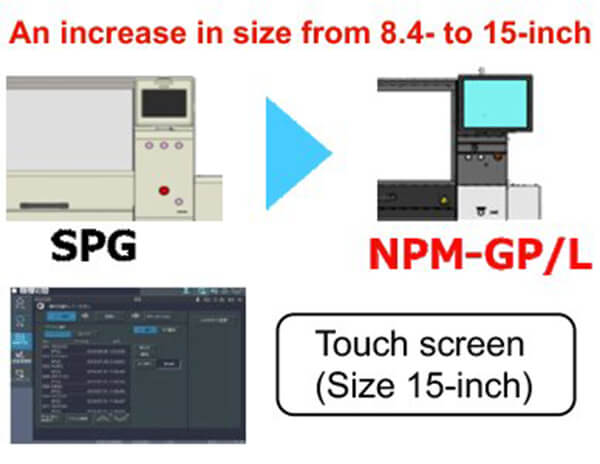

- New operation panel

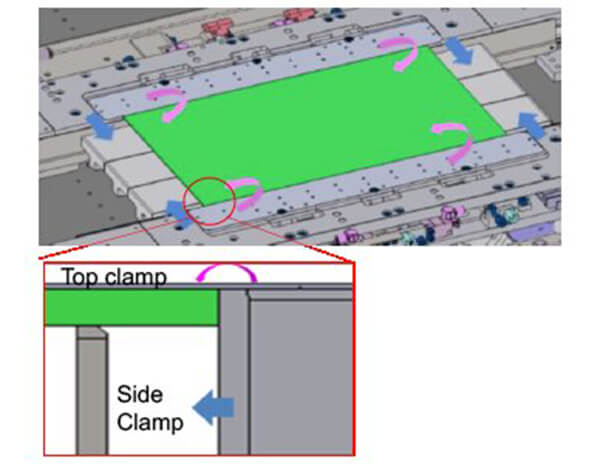

- Moveable Top / side clamper

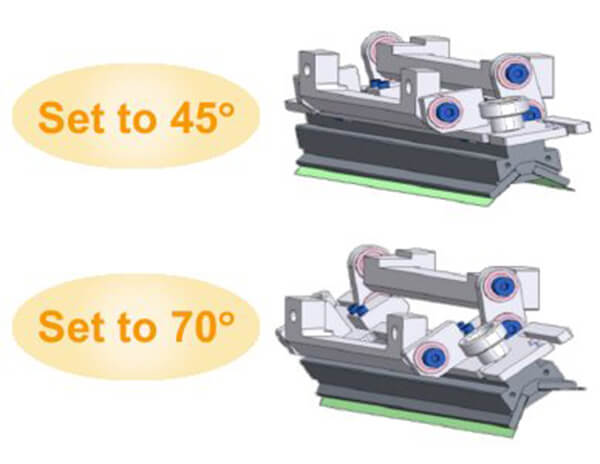

- Attack angle variable squeegee

- Curved edge high filling pressure squeegee

- Process Control & traceability

- PCB pickup blower

- APC-5M Option

Autonomous Factory & Smartification

The fully automated printing solution is part of the "Autonomous Factory" Concept - a factory that immediately responds to every situation and continues to evolve autonomously. Ensuring the production of non-defective items through the integrated control of autonomous uninterrupted mounting lines and floors independent of any human intervention and judgment.

Features

Increased Production Time:

(1) Reduces machine availability losses through automation of operations required for model changeover.

(2) Reduces machine performance losses through automation of operations involved in production.

(3) Increases production time by monitoring machine conditions and thereby performing maintenance at right times.

Maintenance of printing quality at a consistently high level:

Reduces losses due to defective items through various functions that actualizes consistently high-quality printing capable of responding to any changes in 5M.

Support for line solution:

Realizes high-quality line production through M2M (APC-5M) closed loop advances process control

Edge devices, automation functions, and 5M process control to make autonomous factories a reality

5M process control

- Material and machine condition monitoring to automatically change machine parameters

- M2M function with inspection machines to optimize printing position and volume

Supporting automation functions

- Automated model changeover work

- Automated work during production

Improved basic performance

- Printing cycle time: 12 seconds, repeatability of positioning: ± 3.8 μm

- Supporting high accuracy/density printing

Features and Benefits of “Screen Printer NPM-GP/L”

Monitoring and control of material and machine condition using APC-5M

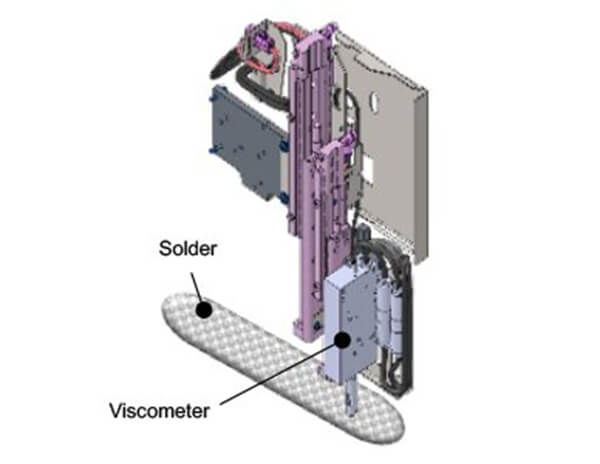

Solder viscosity feedback (optional)

The viscosity of solder on the mask is measured and controlled to maintain the proper viscosity.

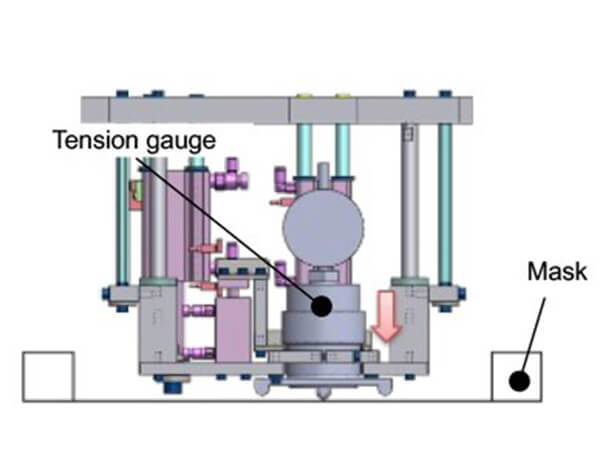

Mask tension feedback (option)

Measure mask tension before screen printing and change plate snap off operation.

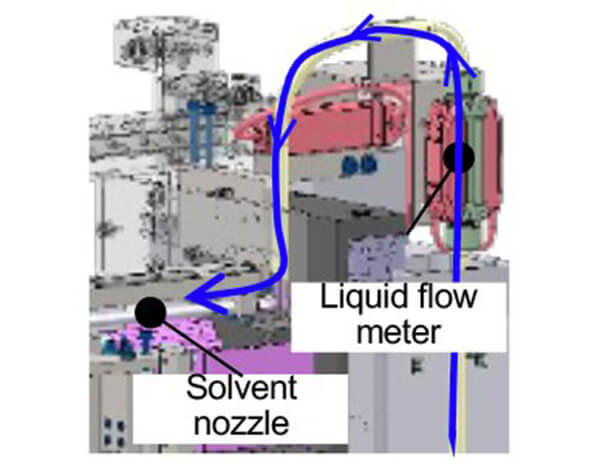

Cleaning solvent discharge feedback (option)

Monitor solvent discharge when wet-cleaning to maintain the proper discharge.

M2M function with inspection machines to optimize printing position and volume

Changing each condition (printing pressure, squeegee speed, and snap-off speed) based on SPI results makes it possible to reach and maintain optimum printing conditions.

Printing position and volume are automatically corrected based on SPI results. Two options are available: Position correction and volume correction.

APC-FB (volume) controls volume by changing the squeegee angle, making it possible to smoothly reach and maintain optimum printing conditions.

APC-FB (position) (option)

APC-FB (volume) (option)*

* The angle variable squeegee (option) is required.

Enhancement of automation and labor-saving functions

Options for automated changeover

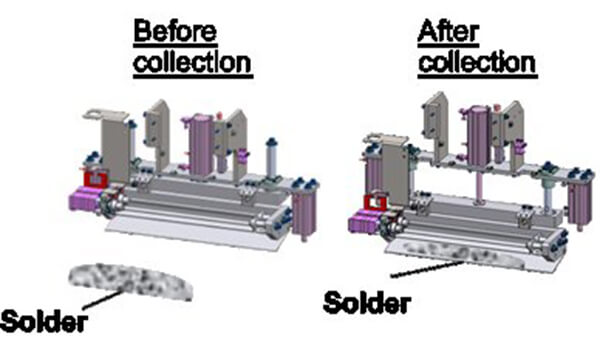

Solder transfer (option)

Automatic collection of solder on mask after printing and automatic feeding of solder on mask for the next production model.

Metal Mask changer (option)

Automatic storing of the mask after the end of production in a magazine at the rear of the machine, and placement of another mask to be used for the next production model in the machine. Capable of stocking up to 10 masks in the magazine and taking masks in and out during production.

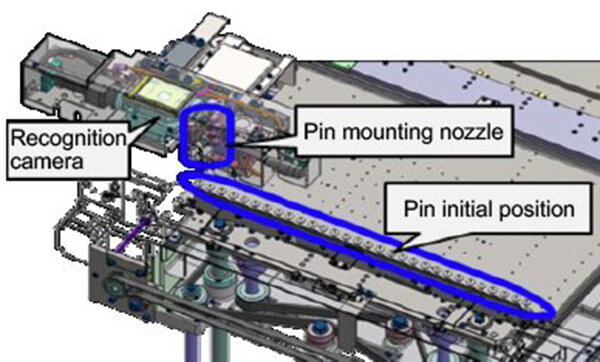

Support pin automatic exchange (option)

Automated collection/arrangement of support pins during changeover to save manpower.

Options for automated production

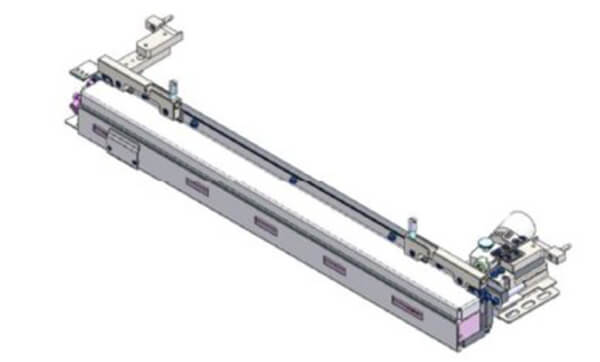

Perforated pot type automatic solder supply (option)

Solder supply automated to promote labor saving and operation without interruption.

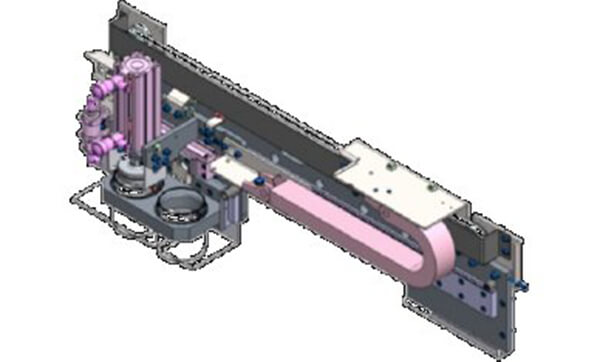

Paper-free wiping unit (option)

Cleaning without using cleaning paper or solvents Use of paper and solvents can be reduced.

Paper-free wiping unit (option)

Cleaning without using cleaning paper or solvents Use of paper and solvents can be reduced.

Solder leak prevention block (option)

Magnet reaction force achieves contact with the mask to reduce lateral solder leakage in printing. Simple structure for easy cleaning.

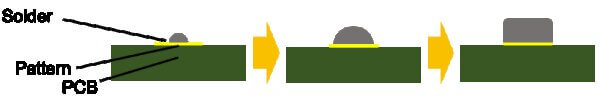

Supporting high accuracy/density printing

Attack angle variable squeegee (option)

The set squeegee angle can be adjusted, using the front and rear squeegee vertical axes, between 45° and 70° in 1 degree increments.

Top/side clamper (movable type) (Option)

Pressing down on PCB edge faces increases screen printing quality of warped PCB.

Either PCB upper or side face can be selected for correction.

New operation panel

A large-sized panel (15-inch) introduced to increase ease of use and visibility.

Screen configuration reviewed (a reduction in the number of screens) to decrease the screen handling time required.

| Model Number | NM-EJP2B |

| PCB dimensions (mm) | L 50 mm × W 50 mm to L 510 mm × W 510 mm |

| PCB exchange | 12.0 s including transport , PCB positioning , PCB recognition , printing , each cleaning operation (When PCB = L 250 mm × W 150 mm) |

| Repeatability | 2 Cpk ± 3.8 μm ± 3σ (Panasonic-specified condition) |

| Printing Accuracy | 2 Cpk ±15.0 μm ± 6σ (Panasonic-specified condition) _x000D_ *CeTaQ measuring machine used |

| Screen frame dimensions | L 736 mm × 736 mm_x000D_ L 750 mm × 750 mm_x000D_ L 650 mm × 550 mm_x000D_ L 600 mm × 550 mm_x000D_ L 550 mm × 650 mm_x000D_ L 584 mm × 584 mm_x000D_ L 736 mm × 584 mm_x000D_ L 584 mm × 736 mm |

| Electric Source | Single-phase AC 200 V ±10 V / AC 220 V ±10 V / AC 230 V ±10 V / AC 240 V ±10 V (Taps can be changed), Max.3.3 kVA |

| Pneumatic Source | 0.5 Mpa, 30 L / min (A.N.R.) (motor vacuum specs), 400 L / min (A.N.R.) (ejector vacuum specs) |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky