Nordson SQ3000™ Multi-Function for 3D AOI SPI & CMM SMT Inspection Machine

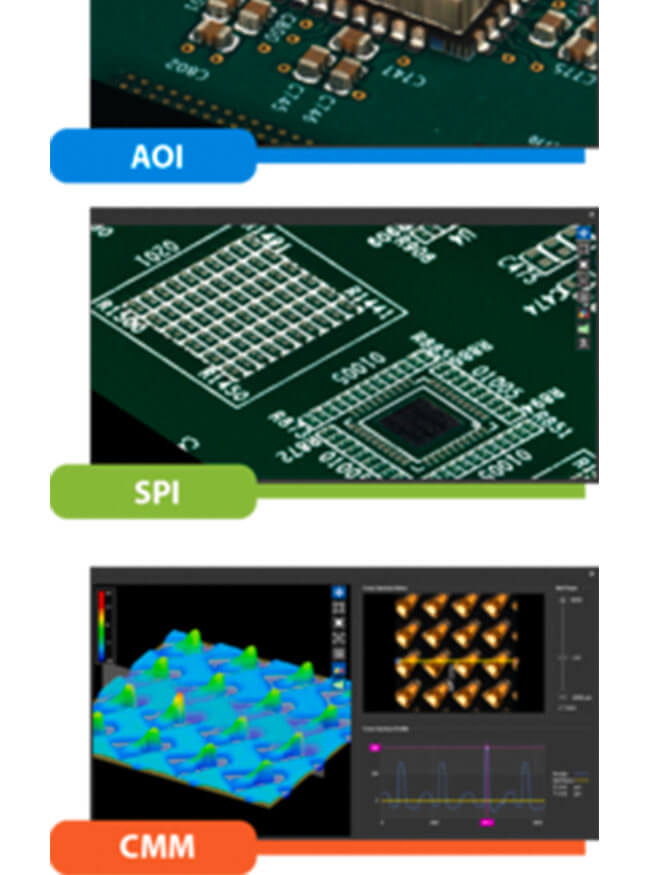

The SQ3000 is an all-in-one solution that’s loaded with powerful tools that cover inspection and measurement for Automated Optical Inspection (AOI), Solder Paste Inspection (SPI) and coordinate measurement (CMM) applications.

SQ3000 for an AOI system is also available.

Overview

Metrology Grade Accuracy

Attain highly accurate data with the industry-leading Multi-Reflection Suppression® (MRS®) sensor technology that meticulously identifies and rejects reflections caused by shiny components and reflective solder joints. Effective suppression of multiple reflections is critical for highly accurate measurement, making MRS an ideal technology for a wide range of applications including those with very high quality requirements.

High Speed Inspection

Speed inspection with the MRS sensor that simultaneously captures and transmits multiple images in parallel, while highly sophisticated fusing algorithms merge the images together, delivering microscopic image quality at production speed.

Fast, Smart, Easy-to-use software

Reduce training efforts and minimize operator interaction with the AOI software’s intuitive interface, multi-touch controls and 3D image visualization tools take ease of use to a whole new level.

Speed programming with AI2 (Autonomous Image Interpretation) to keep it simple – no parameters to adjust or algorithms to tune.

Attain full-fledged machine-level to factory-level SPC capability with powerful historical analysis and reporting tools included in CyberReport™. Improve traceability for process verification and yield improvement.

|

Specification MRS Sensors |

||

|

Inspection Speed |

Standard MRS Sensor: 40 cm²/sec (2D+3D) |

High-Resolution MRS Sensor: 20 cm²/sec (2D+3D) |

|

High-Speed MRS Sensor: 50 cm²/sec (2D+3D) |

Ultra-High Resolution MRS Sensor: 15 cm²/sec (2D+3D) |

|

|

Field of View (FOV) |

Standard MRS Sensor: 36 x 30 mm |

High-Resolution MRS Sensor: 26 x 26 mm |

|

High-Speed MRS Sensor: 36 x 36 mm |

Ultra-High Resolution MRS Sensor: 21 x 21 mm |

|

|

X Y Resolution |

Standard MRS Sensor and High-Speed MRS Sensor: 10µm |

|

|

High-Resolution MRS Sensor and Ultra-High Resolution MRS Sensor: 7µm |

||

|

Component Types Inspected |

Standard SMT (chips, J-lead, gull-wing, BGA, etc.), through-hole, odd-form, clips, connectors, header pins, and more |

|

|

Solder Joint and Other Defects |

Gold finger contamination, excess solder, insufficient solder, bridging, through-hole pins |

|

|

Z Resolution |

0.5µm |

|

|

Component Defects |

Missing, polarity, tombstone, billboard, flipped, wrong part, gross body and lead damage, and more |

|

|

Coordinate Measurement |

Line / Distance / X,Y / Mid Line, Inter Point / Regression Shifted, Datum X,Y / LSF X,Y Offset, |

|

|

Capability |

X,Y Offset / Value / Location / List of X,Y Values, Height / Local Height / Regression / Radius, Coplanarity/ Distance to plane / 2nd Order fitting, Difference / Absolute / 2sqrt / VC, Max / Min / Ave / Sigma / Plus / Minus / Multiple |

|

Multi-Function for 3D AOI, SPI & CMM

The SQ3000 offers unmatched accuracy with the revolutionary Multi-Reflection Suppression (MRS) technology by meticulously identifying and rejecting reflections caused by shiny components. Effective suppression of multiple reflections is critical for accurate measurement, making MRS an ideal technology solution for a wide range of applications including those with very high quality requirements.

SQ3000-X™ 3D AOI

SQ3000-X offers expanded capabilities supporting large boards up to 710 x 610 mm, inspecting the most demanding assemblies without compromising measurement accuracy and repeatability.

SQ3000™ 2D AOI

The SQ3000™ with the new high-resolution 2D sensor with enhanced illumination provides perfect, crisp quality images at a 3μm resolution. The four independent white light LED ring light channels provide a great degree of flexibility for inspection and defect review.

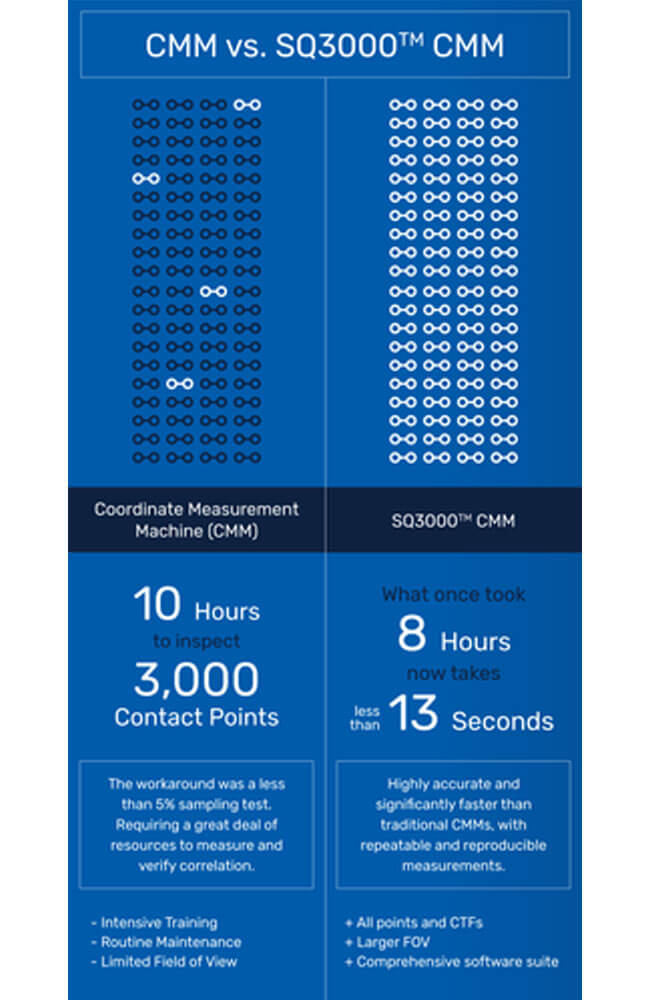

SQ3000™ 3D CMM for AOI

The Ultra High-Resolution MRS sensor enhances the SQ3000 CMM platform, delivering superior performance ideally suited for Socket Metrology and micro-electronics applications where an even greater degree of accuracy and inspection reliability is critical.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky