Mycronic MYPro A40SX Pick and place machine

Flexibility. Turbocharged.

Looking to expand your product mix and your production volumes? Now you can. The MYPro A40™ delivers the high accuracy and fast changeovers you expect from the icon of agility. Whatever jobs tomorrow might throw your way, there’s never been a more versatile way to scale up production and grow your business.

Handle the widest possible range of components and batch sizes with the highest productivity and fastest cycle times.

Key benefits:

Up to 224 feeder positions

Top speed of 29,000 CPH

Full range of components in one machine

Full traceability

Fastest set-ups and changeovers in the industry

Electrical verification of resistors, capacitors, diodes and transistors (optional)

MX7™ mounthead

Flexibility. Turbocharged.

At the heart of the MYPro A40™ is the next-generation MX7™ mounthead technology. The result of several years of in-house development, it packs a powerhouse of independent motors, sensors and servo control technologies into a remarkably compact footprint.

| NEXT-LEVEL FLEXIBILITY | HIGH-SPEED PERFORMANCE | PRECISION ENGINEERING |

| • Mount six times larger components up to 45x45x15 mm | • 48% faster top placement speeds | • Low-maintenance modular design |

| • 14 independent Z and Theta motors | • 7 high-precision vacuum sensors for low-force placement of less than 2N | |

| • Mount long components up to 150x40x15 mm | ||

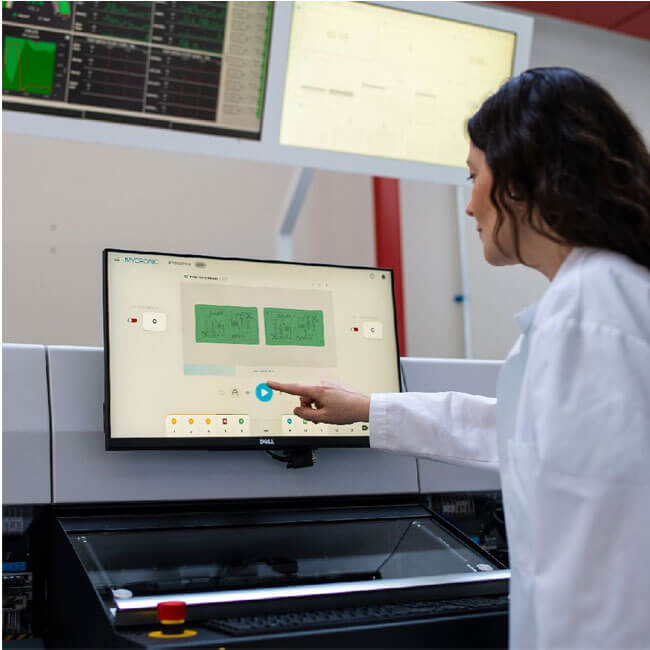

Graphical user interface

Intuitive interface design

No modern production environment is complete without the most streamlined user interface. On the MYPro A40™, this means a GUI that raises the visibility of vital process data while providing simple, intuitive touchscreen guidance. It makes operator training simple, day-to-day functions more accessible and program settings virtually foolproof.

Agilis™ - The most efficient feeding system

Mycronic’s modular Agilis™ component feeding system is designed for accuracy, ease of use and convenience. It gains unrivalled flexibility from a combination of intelligent feeders and magazines for tapes and sticks.

Our unique Agilis™ feeders with no moving parts are easier and quicker to load than any other on the market. And by keeping preloaded Agilis feeders on hand, you can perform set-ups and changeovers even faster.

Since all Mycronic magazines can be replenished while the machine is running, you never have to stop production if you run out of components.

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky