Manncorp MC1200 Solder paste printer

The MC1200 semi-automatic stencil printer fills application requirements of large-board assemblers with print areas ranging from two feet to nearly four feet in length, making it ideal for LED, backplane, and multi-panel assemblies. This big-board printer is a faster, more accurate replacement for manual printers. It allows the use of the most common frame systems, from 470 x 300mm to 1480 x 470mm and an optional camera system makes for easier alignment of PCB to stencil.

Advanced Features Included as Standard

The MC1200 has double-sided board capability & provides outstanding repeatability of ±0.01 mm. Vertical board/stencil separation ensures clean prints with excellent registration. Plus, the print speed control permits complex, fine-pitch circuit boards to be processed at slower speeds than simpler, less densely populated ones.

An optional dual-camera vision system shows X, Y, and theta alignments on an LCD screen. Once set, all adjustments remain locked-in during the entire run. Once the start button is activated, solder paste application and print stroking take place automatically. Squeegee movement and stencil separation speeds are fully programmable using the control panel.

Oversized Print Area——Custom Sizes Available

The MC1200 features an oversized print area of 1200 x 400 mm (47.3" x 15.75"). Custom print area sizes are also

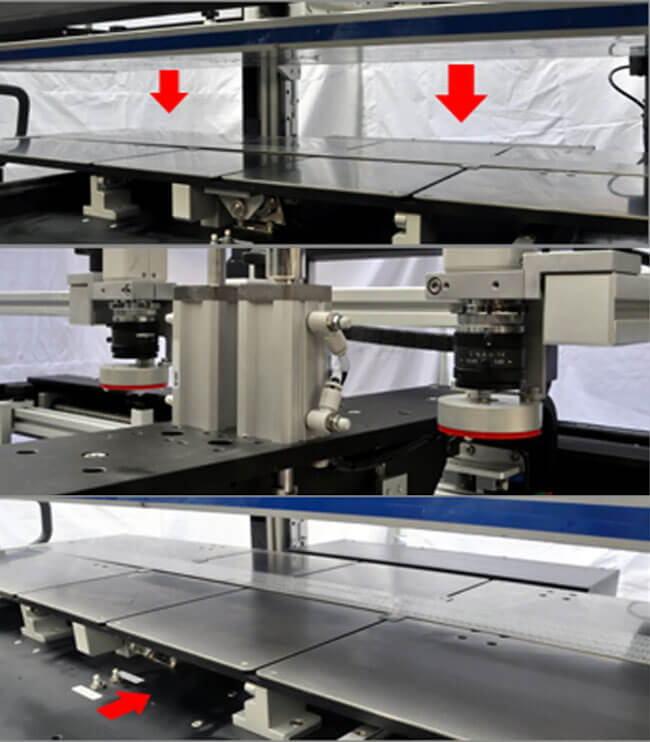

Printing with the MC1200 in Five Easy Steps

Step 1:

Place the PCB board on the slidable working table.

Step 2:

Press the IN button. The working table will move inside automatically.

Step 3:

Press the DOWN button and the stencil will automatically move downward.

Step 4:

Use the magnifying camera to adjust X, Y and theta alignment easily & precisely.

Step 5:

Press the START button to begin printing. The squeegee will then automatically begin to spread the solder paste.

Specifications

| AP1200/AP1500 Specifications | |

| Printing Speed | 20 to 120 mm/s (servo controlled) |

| Vision Alignment | Automatic (AT-Align system) |

| Stencil Frame Size (External Dimensions) | AP1200: 300 x 300 mm to 560 x 1500 mm |

| (11.8" x 11.8" to 22" x 59") | |

| AP1500: 300 x 300 mm to 560 x 1800 mm | |

| (11.8" x 11.8" to 22" x 71") | |

| Board Size | AP1200: Min: 100 x 50 mm Max: 1200 x 300 mm |

| AP1500: Min: 100 x 50 mm Max: 1500 x 300 mm | |

| Board Thickness | 0.4 to 5 mm |

| Board Warpage | Max PCB 1% of diagonal line |

| Blade Type | Metal |

| XY Adjustment | ±10 mm |

| Radial Adjustment | ±2° |

| Printing Accuracy | ±0.04 mm |

| Registration Repeatability | ±0.01 mm |

| PCB Fixation | Screw clamping system and vacuum |

| CCD FOV | 5 x 7 mm |

| Vision Fiducial | Standard fiducial and any pads, 0.5 to 3 mm |

| Air & Power Requirements | 220VAC 50-60 Hz power, 75psi (5 bar) air |

| Dimensions (L x W x H) | AP1200: 91" x 67" x 74" (2300 x 1704 x 1878 mm) |

| AP1500: 103" x 49" x 61" (2600 x 1225 x 1530 mm) | |

| Weight | AP1200: 2646 lbs (1200 kg) |

| AP1500: 3300 lbs (1500 kg) | |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky